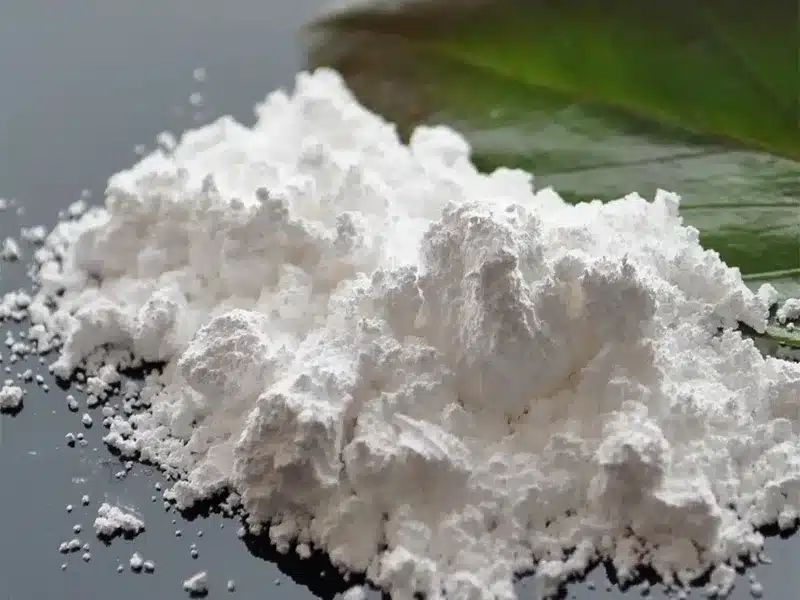

Banlanchem supplies 3N high purity aluminum hydroxide, with Al(OH)₃ purity ≥99.9%, low sodium (Na₂O), and ultra-low impurity content. This high-grade aluminum hydroxide is an ideal precursor for high purity alumina (HPA), ceramic substrates, catalysts, and other advanced applications where material consistency is critical.

CAS No.: 21645-51-2

Chemical Formula: Al(OH)₃

Grade: 3N (99.9%)

Key Features

- Aluminum hydroxide purity ≥ 99.9% (3N)

- Low Na₂O, SiO₂, and Fe₂O₃ impurities

- Excellent thermal stability and crystal phase uniformity

- Suitable for ultra-high purity alumina production

- Consistent particle size distribution

For a scientific overview of aluminium hydroxide compounds including ATH, visit our article: What is Alumina Trihydrate (ATH)?

Physical and chemical index of 3N high purity Aluminum Hydroxide

| Product name | Sippm | Feppm | Nappm | Cappm | Nippm | Mgppm | Cuppm | Crppm | Tippm | Particle sizeD50(um) | Moisture% |

| H-P-999 | 15 | <3 | 2000 | <3 | <1 | <1 | <1 | <2 | 1 | 35~45 | 15-20 |

Applications of 3N High Purity Aluminum Hydroxide

3N High-Purity Aluminum Hydroxide (≥99.9% Al(OH)3) is a premium-grade material used in advanced technical applications requiring ultra-low impurities and excellent thermal stability. It serves as a key raw material in the production of high-purity alumina (HPA), electronic ceramics, catalysts, LED substrates, and polishing abrasives.

1. High-Purity Alumina (HPA) Production

3N aluminum hydroxide is calcined to produce high purity alumina used in LED substrates, lithium battery ceramic coatings, optical glass, and semiconductors. The ultra-low impurity level ensures consistency in high-end ceramic and electronic applications.

2. LED Sapphire Substrates

As a critical feedstock for sapphire crystal growth, 3N-grade Al(OH)3 is converted to alumina, then used to produce LED substrates. High purity improves crystal clarity, thermal performance, and chip efficiency.

3. Electronic Ceramics & Technical Ceramics

It is used in the fabrication of ceramic insulators, MLCC capacitors, and high-frequency substrates. Its chemical stability and low sodium content are essential for dielectric reliability.

4. Polishing Applications

After calcination, 3N aluminum hydroxide is used to produce alumina abrasives for CMP (Chemical Mechanical Polishing), glass lens polishing, and surface finishing in semiconductors and optics.

5. Catalyst Carriers

Used to synthesize high-purity pseudoboehmite and activated alumina for petrochemical, gas purification, and fine chemical applications. The low metal oxide content ensures superior catalyst support performance.

6. Lithium Battery Ceramic Coatings

3N aluminum hydroxide acts as a precursor for ceramic-coated separators in lithium-ion batteries. This enhances thermal stability, puncture resistance, and overall safety during charge/discharge cycles.

7. Optical & Precision Glass Manufacturing

Ideal for manufacturing IR windows, fiber optic components, and specialty glass due to its transparency, purity, and low contamination risk.

8. Scientific & Research Applications

Due to its 99.9% purity, it is often used as a laboratory-grade reagent and base material in the development of next-generation ceramic and alumina technologies.

Summary Table: Key Application Areas

| Application | Typical Use | Purity Requirement |

|---|---|---|

| HPA Production | LED substrates, lithium batteries, optics | ≥99.9% |

| LED Industry | Sapphire crystal growth | ≥99.9% |

| Electronic Ceramics | Capacitors, insulators, substrates | ≥99.9% |

| Polishing Materials | CMP slurry, glass, metals | ≥99.9% |

| Catalyst Supports | Pseudoboehmite, activated alumina | ≥99.9% |

| Battery Coatings | Ceramic-coated separators | ≥99.9% |

| Optical Glass | IR windows, fiber optics | ≥99.9% |

| Scientific Use | Reagents, nano-alumina, research | ≥99.9% |

Banlanchem – Trusted Supplier of High-Purity Aluminum Hydroxide for Advanced Materials.

Packaging & Storage

Standard packaging includes 25kg kraft paper bags with PE lining, 500kg or 1000kg jumbo bags upon request. Store in dry, ventilated area to avoid moisture absorption.

Why Choose Banlanchem?

- ISO-certified production with strict quality control

- Custom specifications available on request

- Stable global supply chain and fast shipping

- Technical support from experienced materials engineers

FAQ

What does 3N mean in aluminum hydroxide?

3N refers to 99.9% purity (three nines) in the aluminum hydroxide composition. This is critical for high-end applications requiring minimal trace impurities.

How is 3N aluminum hydroxide used in LED substrates?

3N aluminum hydroxide is calcined to form high-purity alumina, which is then processed into sapphire substrates used in LED production for its thermal and electrical insulation properties.

Can you provide customized particle sizes?

Yes, Banlanchem offers particle size control according to customer requirements, including D50 and D90 distributions.

What is the difference between 3N and 4N aluminum hydroxide?

The key difference lies in purity: 3N is ≥99.9%, while 4N is ≥99.99%. The higher the purity, the more suitable it is for critical semiconductor and optical applications.

Related Products

- 4N High Purity Aluminum Hydroxide

- High Purity Alumina (HPA)

- Pseudoboehmite Alumina

Get a Quote

Interested in 3N High Purity Aluminum Hydroxide? Contact Banlanchem today to receive technical support, pricing, and a sample.