Alumina Trihydrate (ATH), chemically known as Aluminum Hydroxide (Al(OH)3), is a high-purity inorganic material widely used in flame retardant systems, smoke suppression applications, and industrial filler formulations. As a professional alumina trihydrate manufacturer and supplier, BanlanChem provides stable-quality ATH products for global industrial buyers seeking reliable supply, consistent specifications, and factory-direct pricing.

Our alumina trihydrate products are manufactured in China under controlled production processes to ensure consistent particle size, high whiteness, and stable chemical composition. We support bulk orders, wholesale distribution, and long-term supply contracts for customers in plastics, cables, rubber, coatings, and construction material industries.

Contents

- What Is Alumina Trihydrate (ATH)?

- Chemical & Physical Properties

- ATH Production Process Overview

- Flame Retardant & Smoke Suppression Mechanism

- Industrial Applications of Alumina Trihydrate

- ATH Grade Selection Guide

- Typical Specifications & Technical Data

- Processing & Performance in Compounds

- Packaging, Logistics & Export Supply

- Quality Control & Documentation

- Why Choose BanlanChem as Your ATH Supplier

- Frequently Asked Questions

- Request Price, Samples & Technical Support

What Is Alumina Trihydrate (ATH)?

Alumina trihydrate is a hydrated form of aluminum oxide, containing three molecules of water chemically bonded to aluminum hydroxide. In industrial markets, ATH is primarily valued for its endothermic decomposition behavior, which releases water vapor when exposed to high temperatures.

This property makes ATH one of the most widely used halogen-free flame retardant fillers in polymer-based materials. Unlike halogen-containing flame retardants, alumina trihydrate does not release corrosive or toxic gases during combustion, making it suitable for environmentally regulated and safety-sensitive applications.

In addition to flame retardancy, ATH functions as a functional filler that improves whiteness, surface finish, and cost-efficiency in a wide range of industrial formulations.

Chemical & Physical Properties of Alumina Trihydrate

Understanding the chemical and physical properties of ATH is essential for selecting the correct grade for specific industrial uses. While exact values may vary depending on production method and grade, alumina trihydrate generally exhibits the following characteristics:

- High aluminum hydroxide purity

- White powder appearance

- Low impurity levels

- Stable chemical structure under normal conditions

- Endothermic decomposition starting around 200°C

Because ATH decomposes before many polymers ignite, it helps delay ignition, reduce flame spread, and lower smoke density during fire exposure.

ATH Production Process Overview

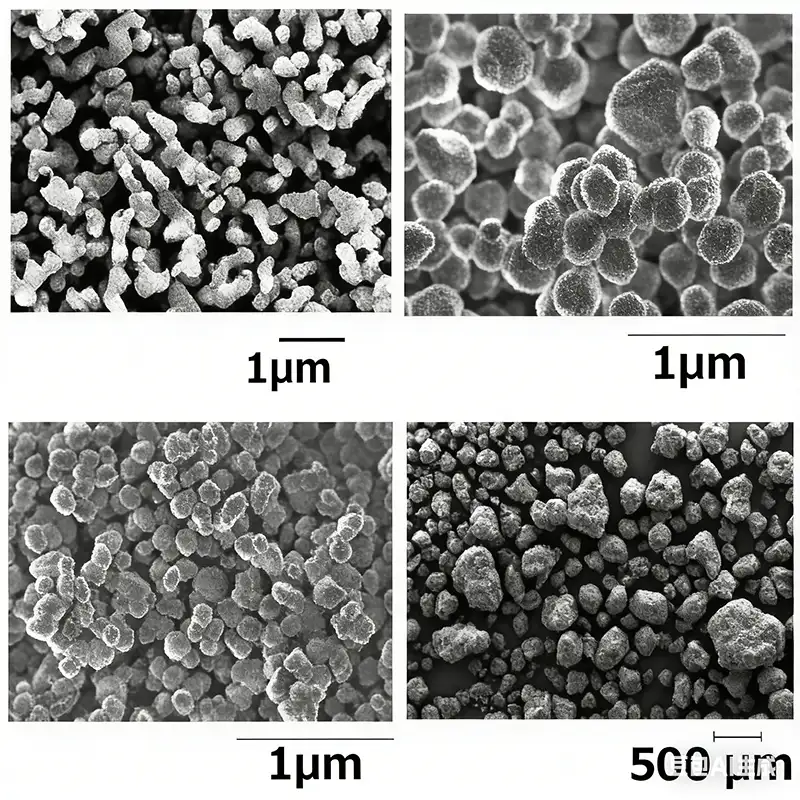

Industrial alumina trihydrate is typically produced through controlled precipitation from aluminum-containing solutions. The production process directly affects particle morphology, particle size distribution, and surface characteristics.

At BanlanChem, ATH production focuses on:

- Controlled crystal growth

- Consistent filtration and drying

- Strict impurity control

- Batch-to-batch stability

These steps ensure that each shipment meets industrial processing requirements and delivers predictable performance in downstream applications.

Flame Retardant & Smoke Suppression Mechanism

The flame retardant effect of alumina trihydrate is primarily based on its endothermic decomposition. When ATH is exposed to heat, it absorbs energy and releases chemically bound water in the form of steam.

This process provides multiple protective effects:

- Heat absorption lowers material temperature

- Water vapor dilutes flammable gases

- Residue forms a protective barrier

- Reduced smoke and toxic gas release

Because ATH is inorganic and halogen-free, it is widely used in low-smoke, low-toxicity material systems required by modern safety regulations.

Industrial Applications of Alumina Trihydrate

1. Wire & Cable Compounds (LSZH / HFFR)

One of the largest application areas for alumina trihydrate is in low-smoke zero-halogen (LSZH) cable compounds. ATH helps cable materials meet flame retardancy and smoke density requirements while maintaining acceptable mechanical properties.

2. Plastics & Polymer Compounds

ATH is commonly used in polyethylene (PE), EVA, polypropylene (PP), and other polymer systems as a flame retardant filler or functional additive.

3. Rubber & Elastomer Systems

In rubber compounds, ATH improves flame resistance and contributes to smoke suppression without introducing corrosive combustion byproducts.

4. Coatings, Sealants & Adhesives

In coatings and sealant formulations, alumina trihydrate enhances whiteness, viscosity control, and fire resistance.

5. Construction & Artificial Stone Materials

ATH is used in solid surface materials, FR panels, and construction products to improve fire performance and aesthetic appearance.

For a broader explanation of industrial uses, you may also refer to: Aluminum Hydroxide Uses in Industrial Applications.

ATH Grade Selection Guide

Selecting the correct alumina trihydrate grade is critical for achieving optimal performance. Grade selection is typically based on:

- Particle size distribution

- Surface treatment requirements

- Target loading levels

- Processing temperature

BanlanChem provides technical guidance to help customers match ATH grades to their specific processing conditions and performance goals.

In flame-retardant applications, alumina trihydrate is often compared with aluminum hydroxide in terms of thermal behavior and smoke suppression. To better understand the difference between alumina trihydrate and aluminum hydroxide, this detailed comparison explains how each material performs in industrial use.

Typical Specifications & Technical Data

| Model | Al(OH)3 ≥ | AL2O3 ≥ | SiO2 ≤ | Fe2O3 ≤ | Na2O ≤ | D50 (μm) | Oil Absorption Ml/100g≤ | PH | Moisture % | Whiteness % |

| H-WF-1 | 99.6 | 64.5 | 0.05 | 0.02 | 0.25 | 1.5-1.8 | 37.5 | 8.5 | 0.25 | 99.2 |

| H-WF-3 | 99.6 | 64.5 | 0.05 | 0.02 | 0.25 | 2.5-3.5 | 33.8 | 8.5 | 0.25 | 95 |

| H-WF-5 | 99.6 | 65 | 0.03 | 0.02 | 0.25 | 4.965 | 33.6 | 8.5 | 0.25 | 95 |

| H-WF-8 | 99.6 | 65 | 0.03 | 0.02 | 0.25 | 8.532 | 32 | 8 | 0.25 | 92/98 |

| H-WF-10 | 99.7 | 65 | 0.03 | 0.02 | 0.25 | 9.684 | 29 | 8 | 0.25 | 92/96/98 |

| H-WF-15 | 99.6 | 65 | 0.03 | 0.02 | 0.25 | 14.932 | 22 | 8 | 0.25 | 92/95/98 |

| H-WF-20 | 99.7 | 65 | 0.03 | 0.02 | 0.25 | 19.731 | 21 | 8 | 0.25 | 90/95/98 |

| H-WF-25 | 99.8 | 65 | 0.03 | 0.02 | 0.25 | 26.138 | 21 | 8 | 0.25 | 98 |

| H-WF-75 | 99.8 | 65 | 0.02 | 0.02 | 0.25 | 74.654 | 20 | 7.5 | 0.25 | 97 |

| H-WF-100 | 99.8 | 65 | 0.02 | 0.02 | 0.25 | 90.537 | 19 | 7.5 | 0.25 | 96 |

Processing & Performance Considerations

In polymer and rubber processing, ATH loading levels can be adjusted based on flame retardancy requirements and mechanical property targets. Proper dispersion and compounding techniques are essential for achieving consistent performance.

Packaging, Logistics & Export Supply

- 25kg bags

- 1,000kg jumbo bags

- EXW / FOB / CIF terms

- Global export experience

Quality Control & Documentation

- Certificate of Analysis (COA)

- MSDS / SDS

- Product specification sheets

- Batch traceability

Why Choose BanlanChem as Your Alumina Trihydrate Supplier

- Factory-direct supply from China

- Stable production capacity

- Customized grade support

- Export-ready documentation

- Professional B2B service team

Frequently Asked Questions

Is alumina trihydrate the same as aluminum hydroxide?

In industrial markets, alumina trihydrate typically refers to high-purity aluminum hydroxide used as a flame retardant filler. Terminology may vary by region and application.

Can ATH replace halogen flame retardants?

In many low-smoke and halogen-free systems, ATH is widely used as an alternative to halogen-based flame retardants.

Request Price, Samples & Technical Support

For factory pricing, technical consultation, or bulk supply inquiries, please contact BanlanChem:

Related product: Aluminum Hydroxide Product Page