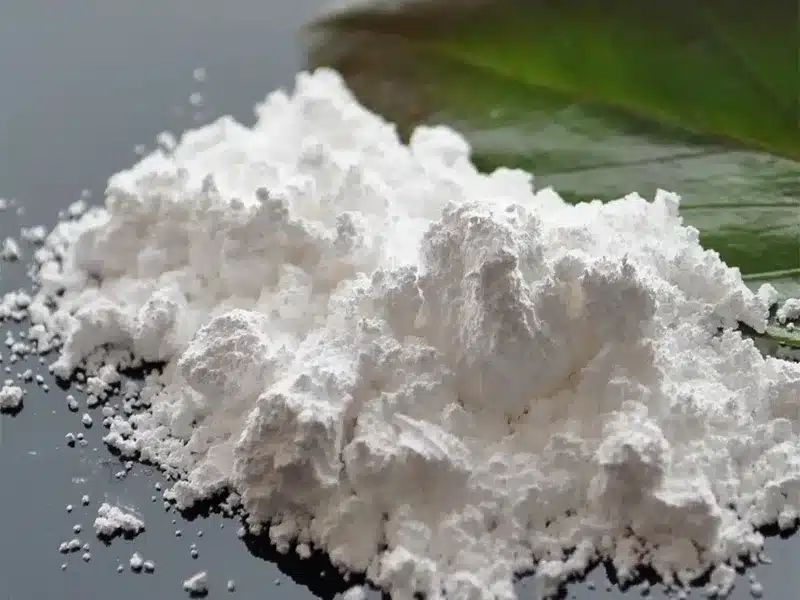

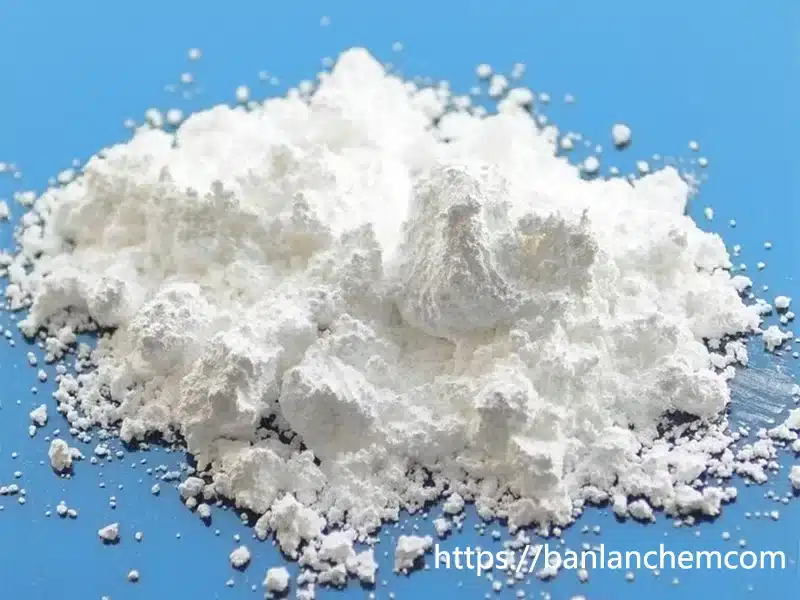

Aluminium Hydroxide Fire Retardant (ATH) – Halogen-Free Flame Retardant Filler for Cables & Polymers

Banlanchem is a professional manufacturer of aluminium hydroxide fire retardant (ATH)—a halogen-free, high-whiteness mineral flame retardant and smoke suppressant for LSZH cable compounds, plastics, rubber, thermosets, coatings and sealants. Our engineered grades are optimised for extrusion and moulding with controlled particle size distributions, low alkalies, and optional surface treatments to improve dispersion and mechanical properties. Free samples and COA/TDS are available on request.

Common search terms: aluminium hydroxide fire retardant, aluminium hydroxide flame retardant, ATH flame retardant filler.

1) Why Choose Aluminium Hydroxide (ATH) as a Fire Retardant?

Aluminium hydroxide—also known as alumina trihydrate (ATH)—is the most widely used halogen-free mineral flame retardant. When processed into polymer compounds, ATH increases resistance to ignition, reduces peak heat release rate, and notably suppresses smoke and toxic gas. Compared to halogenated systems, ATH helps formulators meet modern environmental and regulatory requirements while maintaining favourable cost-performance.

- Halogen-free: compliant with RoHS/REACH-oriented specifications and LSZH targets.

- Smoke suppression: water release dilutes combustible gases and cools the substrate.

- High whiteness: ideal for light-coloured cable jackets, profiles, and artificial stone.

- Broad compatibility: widely used in EVA/PE, EPDM, XLPE, UPR, acrylics, epoxies, and more.

- Scalable cost: competitive compared with speciality non-halogen systems.

2) Flame Retardant Mechanism & Benefits

ATH decomposes endothermically around 200–220 °C, absorbing heat and releasing chemically bound water:

2 Al(OH)3 → Al2O3 + 3 H2O (g)

This mechanism provides three synergistic effects:

- Cooling – heat absorption slows temperature rise and delays ignition.

- Dilution – water vapour reduces combustible gas concentration and oxygen near the flame.

- Barrier – residual alumina promotes a protective inorganic layer that hinders mass/heat transfer.

As a result, aluminium hydroxide flame retardant can improve ratings in tests such as LOI, UL-94 (material-dependent), and contribute to cable standards for low smoke zero halogen (LSZH) performance when properly formulated with synergistic additives and optimal particle sizes.

3) Product Grades & Typical Specifications of

Aluminium Hydroxide Fire Retardant

Banlanchem supplies multiple ATH grades tailored for different processing and performance requirements. Typical parameters include D50 particle size, whiteness, Na2O, moisture, and surface treatment.

|

Specification |

Brand |

|||||

|

H-WF-8 |

H-WF-10 |

H-WF-10LV |

H-WF-14LV |

H-WF-14 |

||

|

Chemical Composition % |

Al(OH)3 |

99.6 |

99.6 |

99.6 |

99.6 |

99.6 |

|

SiO2 |

0.05 |

0.05 |

0.03 |

0.05 |

0.05 |

|

|

Fe2O3 |

0.02 |

0.02 |

0.015 |

0.02 |

0.02 |

|

|

Na2O |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

|

|

Na2O(s) |

0.03 |

0.03 |

0.15 |

0.03 |

0.03 |

|

|

Absorption of oil ml/100g |

33 |

33 |

30 |

29 |

32 |

|

|

Whiteness |

96 |

96 |

92 |

95 |

95 |

|

|

Particle size |

D50 |

6-10 |

8-12 |

8-12 |

10-16 |

13-19 |

|

+60mesh |

- |

- |

- |

- |

- |

|

|

+100mesh |

0 |

0 |

0 |

0 |

0 |

|

|

+325 mesh |

3max |

4max |

1max |

15max |

12 |

|

|

Moisture |

0.4 |

0.3 |

0.3 |

0.3 |

0.3 |

|

4) Applications & Formulation Guidance

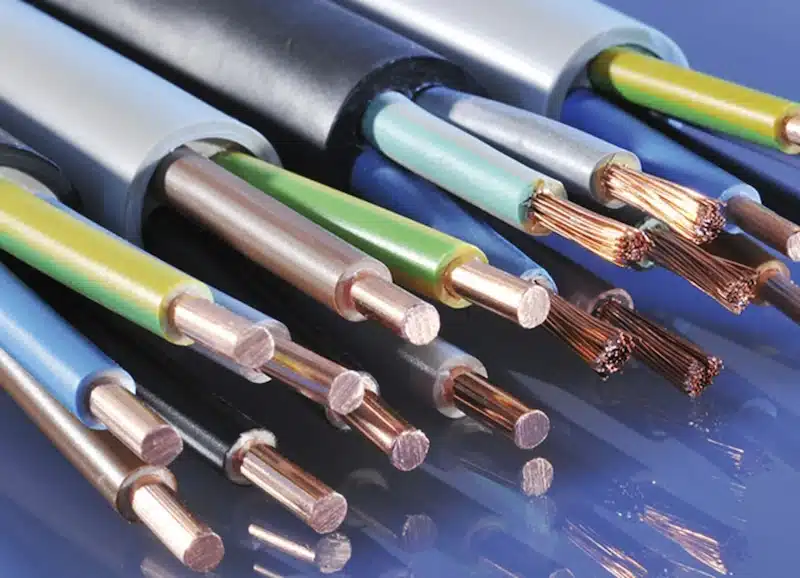

4.1 LSZH Wire & Cable Compounds

ATH is the leading mineral system for low smoke zero halogen cable jackets and insulation. High loadings are typically used—often in the range of 30–60 wt% depending on resin, mechanical targets, and regulatory requirements. Microfine and surface-treated grades improve extrusion smoothness, elongation, and tear strength.

- Resins: EVA, PE, EPDM, XLPE (with crosslinking considerations).

- Synergy: metal hydroxide blends, mineral synergists, lubricants, and coupling agents.

- Processing: ensure adequate screw design, venting, and temperature control to prevent moisture/porosity.

4.2 Plastics, Thermosets & Rubber

In UPR, epoxy, acrylics, TPU, PVC-free formulations, and rubber, aluminium hydroxide flame retardant enhances UL-94 behaviour and reduces smoke. Use microfine grades to balance mechanical properties and surface finish. Silane/stearate treatments may reduce viscosity and improve filler-matrix bonding.

4.3 Coatings, Sealants & Adhesives

ATH provides non-halogen smoke suppression and matting in intumescent and protective coatings, and improves flame-retardant sealants used in construction. Consider low-moisture, narrow PSD grades for stable rheology and smooth films.

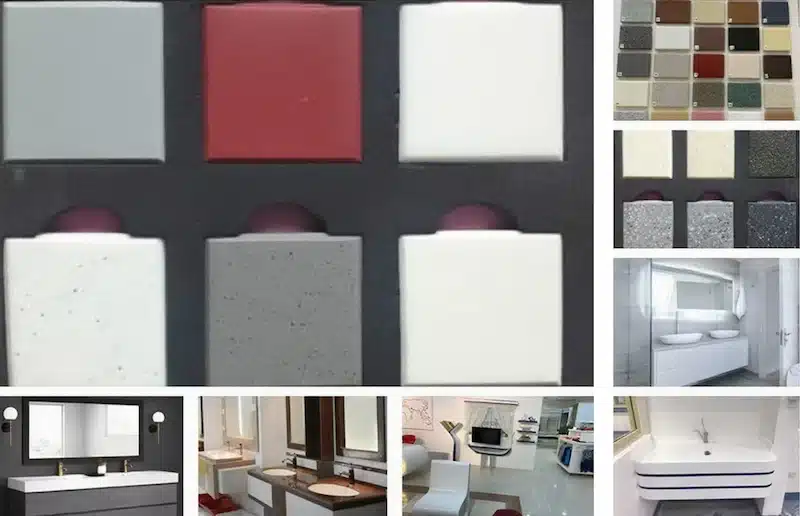

4.4 Artificial Marble / Solid Surface

High-whiteness ATH yields bright, uniform castings with comfortable tactile feel. Proper dispersants and vacuum casting help achieve low voids and consistent gloss. Particle size selection controls translucency and polishability.

5) Processing, Dispersion & Surface Treatment

Successful compounding depends on dispersion and interfacial compatibility:

- Surface treatment: Silane and stearate coatings can reduce compound viscosity, improve filler wet-out, and enhance tensile/elongation at high loadings.

- Feeding: Use reliable gravimetric feeding for consistent loading; pre-dry if ambient humidity is high.

- Shear/temperature: Maintain adequate shear for deagglomeration while avoiding resin degradation; process below onset of ATH dehydration when required.

- Masterbatch approach: For small-scale lines, a high-filler masterbatch can stabilise dispersion and simplify dosing.

6) Quality, COA/TDS, Packaging & Storage

Each batch is tested against specified limits for particle size, moisture, whiteness, and impurities. COA is provided with shipment; TDS and MSDS are available upon request. Standard packaging is 25 kg bags on pallets, with 500–1000 kg FIBCs available for bulk users.

- Storage: Keep dry, sealed, and off the floor; avoid moisture uptake.

- Shelf life: 12 months in original, sealed packaging under recommended conditions.

- Logistics: Export-ready packing; support for documentation and compliance.

7) Aluminium Hydroxide Fire Retardant vs Other Flame Retardants

ATH vs Magnesium Hydroxide (MDH): ATH decomposes ~200–220 °C, suitable for lower-temperature polymers (EVA/PE). MDH decomposes at higher temperature (~330 °C), fitting some higher-processing resins but usually with different rheology and cost. For light colours and smoke performance, ATH remains a first choice in LSZH wiring.

ATH vs Halogenated Systems: Halogens can offer high FR efficiency but face regulatory and smoke/toxicity concerns. ATH meets halogen-free expectations with reliable supply and established know-how in cables, construction and consumer applications.

8) Frequently Asked Questions of Aluminium Hydroxide Fire Retardant

Q1. Is aluminium hydroxide the same as alumina?

No. Aluminium hydroxide is Al(OH)3 (ATH). When heated, it dehydrates to alumina (Al2O3). They serve different functions: ATH is a flame retardant/smoke suppressant, while alumina is used in ceramics, abrasives and refractories.

Q2. What loading levels do I need in LSZH cable?

Formulation-dependent. Many LSZH jackets/insulations use 30–60 wt% ATH. Particle size, surface treatment, and synergists influence mechanicals and extrusion behaviour.

Q3. Do I need surface-treated grades?

Often recommended for high loadings or when you need better dispersion and mechanical balance. Silane or stearate treatments reduce viscosity and improve tensile/elongation.

Q4. Can Banlanchem provide free samples and technical support?

Yes. We are the factory/manufacturer and can provide free samples, TDS/COA, and formulation guidance for your application.

Q5. Is aluminium hydroxide flame retardant safe and compliant?

ATH is halogen-free. Our grades are produced to meet typical industrial compliance needs; contact us for region-specific requirements and documentation.

9) Related Products & Internal Links

- Wet Aluminum Hydroxide for Flame Retardant (LSZH)

- High-Whiteness Aluminum Hydroxide for Filler

- 3N High-Purity Aluminum Hydroxide

- If you need alumina-based abrasives: White Fused Alumina

- Background reading: Surface Modification of Aluminum Hydroxide Powder

- Fundamentals: What is Alumina Trihydrate (ATH)?

- Process differences: Dried vs Wet Aluminum Hydroxide

10) Request Samples & Pricing

Banlanchem is your reliable manufacturer of aluminium hydroxide flame retardant fillers. Tell us your resin system, target standards, and preferred particle size—we will recommend a suitable grade and send free samples with COA/TDS. For bulk orders, OEM/ODM and custom surface treatments are available.