Aluminum hydroxide powder is a widely used inorganic material across flame-retardant, plastics, rubber, cable, and construction industries. It is valued for its excellent flame retardant performance, chemical stability, low toxicity, and environmental safety.

As a professional aluminum hydroxide powder manufacturer, BanlanChem supplies high-purity aluminum hydroxide powder to global industrial customers, compounders, and material distributors. We support factory-direct supply, wholesale orders, and OEM / ODM solutions with stable quality and reliable delivery.

What Is Aluminum Hydroxide Powder?

Aluminum hydroxide powder is an aluminum-based inorganic compound with the chemical formula Al(OH)₃. It appears as a white, fine powder with good dispersion, stable structure, and low toxicity.

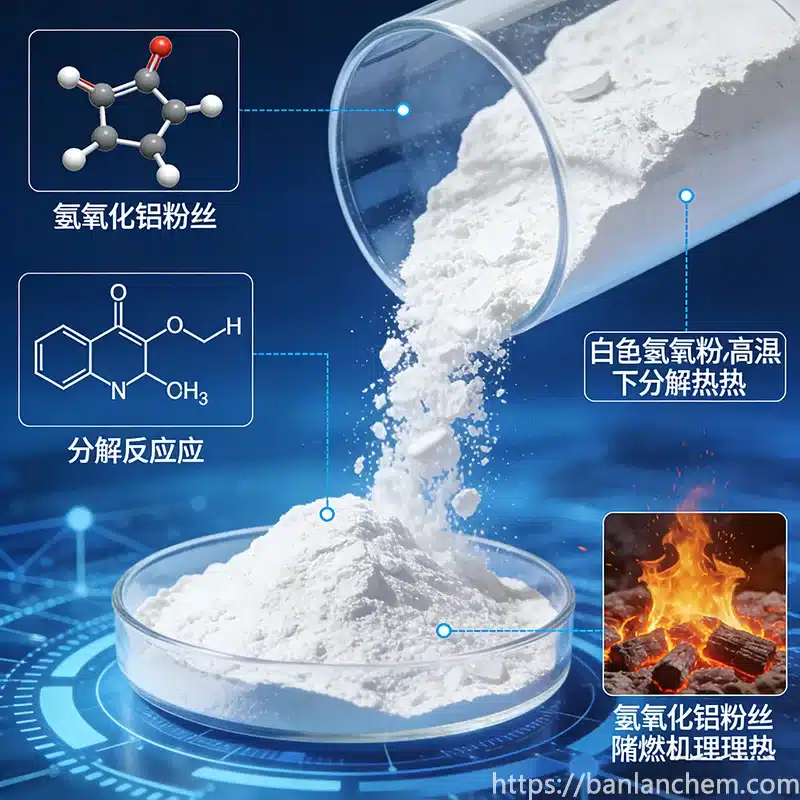

When heated, aluminum hydroxide powder undergoes thermal decomposition and releases water vapor. This endothermic reaction helps absorb heat, dilute flammable gases, and slow down fire spread. Because of this mechanism, aluminum hydroxide powder is widely used as a halogen-free flame retardant filler.

At higher temperatures, aluminum hydroxide powder can be further processed into aluminum oxide materials. For high-temperature or ceramic applications, some customers choose alumina powder with controlled purity and particle size.

At higher temperatures, aluminum hydroxide powder can be further processed into aluminum oxide materials. For high-temperature or ceramic applications, some customers choose alumina powder with controlled purity and particle size.

For a detailed explanation of the definition, properties, and basic uses, you can read our article What Is Aluminum Hydroxide Powder?

Key Properties of Aluminum Hydroxide Powder

Aluminum hydroxide powder combines safety and performance, making it suitable for both industrial and consumer applications.

Key properties include:

- High purity and stable chemical composition

- Excellent flame retardant performance

- Low smoke generation and low toxicity

- Good electrical insulation

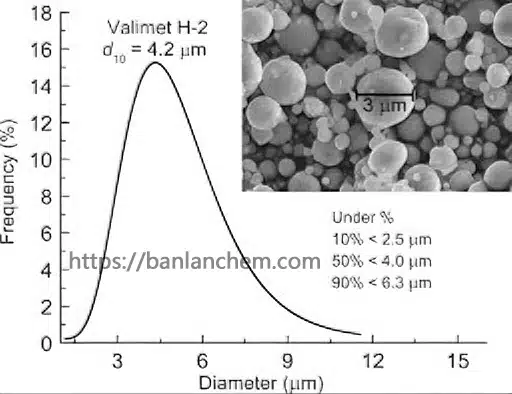

- Fine particle size with good dispersion

These characteristics make aluminum hydroxide powder a preferred material for flame-retardant systems that require environmental compliance and processing stability.

Why Aluminum Hydroxide Powder Is Used as a Flame Retardant

Aluminum hydroxide powder functions as a physical flame retardant. When exposed to high temperatures, it decomposes and releases water vapor.

This flame-retardant mechanism:

- Absorbs heat from the fire source

- Cools down the material surface

- Reduces flammable gas concentration

- Forms a protective residue layer

Unlike halogen-based flame retardants, aluminum hydroxide powder does not release toxic or corrosive gases during combustion. This makes it an ideal choice for halogen-free flame-retardant formulations, especially in cables, plastics, and building materials.

In flame retardant plastics and cable compounds, a dedicated aluminum hydroxide flame retardant grade is often used to achieve better dispersion and stable fire performance.

Main Applications of Aluminum Hydroxide Powder

1. Plastics and Polymers

Aluminum hydroxide powder is widely added to PVC, PE, PP, and engineering plastics. It improves flame resistance while reducing smoke density.

2. Rubber Industry

In rubber compounds, aluminum hydroxide powder enhances fire safety and improves long-term stability.

3. Wire and Cable

Aluminum hydroxide powder is commonly used in cable insulation and sheathing. It helps meet strict fire-safety and electrical standards.

4. Building Materials

It is used in panels, coatings, adhesives, and construction materials to improve fire resistance and thermal performance.

5. Chemical and Industrial Uses

Aluminum hydroxide powder also functions as a filler, pH regulator, and chemical intermediate in various industrial processes.

To explore a wider range of applications across different industries, refer to our comprehensive overview of uses of aluminum hydroxide .

Aluminum Hydroxide Powder Grades

Different applications require different grades of aluminum hydroxide powder.

Common grades include:

- Standard grade for general flame-retardant applications

- Fine particle grade for better dispersion in polymers

- Low sodium grade for high-end and electrical uses

- Surface-treated grade for improved polymer compatibility

At BanlanChem, we help customers select the most suitable aluminum hydroxide powder grade based on processing conditions and performance requirements.

Aluminum Hydroxide Powder vs Alumina Trihydrate

Aluminum hydroxide powder and alumina trihydrate (ATH) are often considered the same material. In most industrial applications, alumina trihydrate is another common name for aluminum hydroxide powder.

However, differences may appear depending on:

- Purity level

- Particle size distribution

- Application focus

For flame-retardant plastics and cables, aluminum hydroxide powder / ATH is commonly used. For high-temperature or ceramic applications, calcined alumina is usually selected instead.

Production Process Overview

Aluminum hydroxide powder is typically produced through a controlled precipitation process. High-purity sodium aluminate solution reacts under carefully controlled conditions.

Key production steps include:

- Precipitation and crystal growth

- Filtration and thorough washing

- Drying and particle size control

- Final quality inspection

A stable factory process ensures consistent quality, uniform particle size, and reliable performance in downstream applications.

After controlled calcination, aluminum-based materials show different physical properties such as higher hardness and thermal stability. In such cases, calcined alumina supplier is often selected for advanced refractory and polishing applications.

Quality Control and Standards

As an experienced aluminum hydroxide powder manufacturer and supplier, BanlanChem places strong emphasis on quality control.

Typical inspection items include:

- Chemical purity

- Particle size distribution

- Moisture content

- Whiteness and appearance

Each batch of aluminum hydroxide powder is tested to meet customer specifications and international industry standards.

Why Choose BanlanChem as Your Aluminum Hydroxide Powder Manufacturer?

BanlanChem is a professional manufacturer, supplier, and wholesale provider of aluminum hydroxide powder.

Our advantages include:

- Factory-direct supply with stable capacity

- Consistent quality and batch stability

- OEM / ODM customization support

- Export experience for global markets

- Technical support for application selection

We focus on building long-term, reliable partnerships with customers worldwide.

When selecting a long-term partner, supplier reliability is an important factor. To better understand key evaluation points, you may also read our guide How to Choose a Reliable Aluminum Hydroxide Powder Supplier .

Packaging, Supply & Wholesale Options

Aluminum hydroxide powder is available in:

- Standard industrial packaging

- Bulk supply for wholesale orders

- Customized packaging upon request

We support large-volume supply, flexible MOQ, and stable long-term cooperation.

Frequently Asked Questions

Is aluminum hydroxide powder safe?

Yes. Aluminum hydroxide powder is non-toxic and environmentally friendly when used correctly.

What is aluminum hydroxide powder used for?

It is mainly used as a flame retardant filler in plastics, rubber, cables, and building materials.

Is aluminum hydroxide powder the same as ATH?

Yes. ATH (alumina trihydrate) is another common name for aluminum hydroxide powder.

What particle size is best for flame retardant applications?

Fine and ultra-fine grades are typically preferred for better dispersion and stable fire performance.

Do you provide OEM or wholesale supply?

Yes. We provide OEM, ODM, and wholesale aluminum hydroxide powder with reliable quality and supply capacity.

For detailed specifications, technical support, or quotation requests, please contact BanlanChem’s technical team.

We are ready to support your aluminum hydroxide powder sourcing needs.