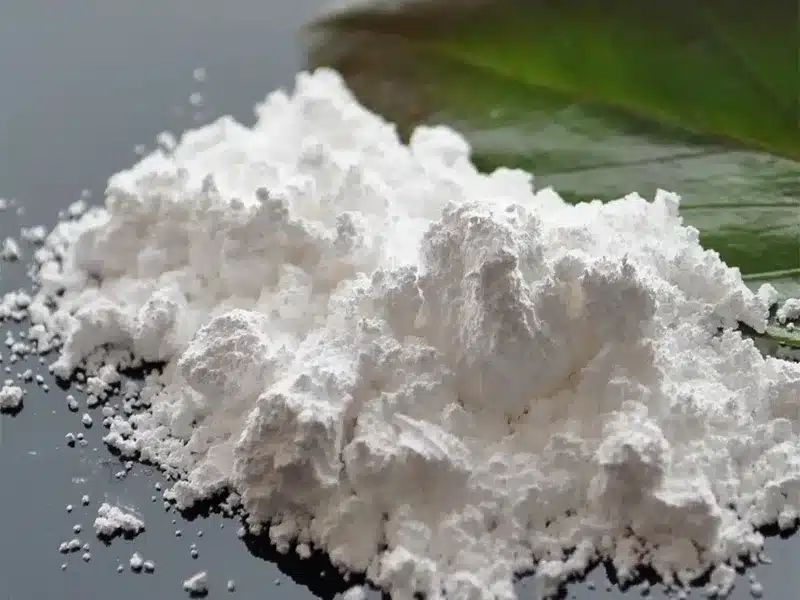

Superfine Grade Aluminum Hydroxide for Cables (ATH), also known as alumina trihydrate, is an essential flame retardant and filler used in cable manufacturing. Its high purity, low oil absorption, and excellent whiteness make it a preferred choice for LSZH (Low Smoke Zero Halogen) cables and various other cable applications.

| Brand | Chemical composition( % ) | DOP | Whiteness | Particle size | Moisture | |||||

| Al(OH)3≥ | SiO2≤ | Fe2O3≤ | Na2O≤ | Na2O(2)≤ | ml/100g≤ | %≥ | D50μm | +325mesh≤ | %≤ | |

| H-WF-1S | 99.3 | 0.02 | 0.01 | 0.5 | 0.05 | 55 | 97 | 0.5-1.0 | 0.1 | 0.5 |

| H-WF-1 | 99.7 | 0.02 | 0.01 | 0.3 | 0.03 | 45 | 97 | 0.8-1.4 | 0.1 | 0.35 |

| H-WF-2N | 99.7 | 0.02 | 0.01 | 0.3 | 0.03 | 45 | 96 | 1.2-2 | 0.1 | 0.35 |

| H-WF-5 | 99.6 | 0.1 | 0.02 | 0.3 | 0.03 | 32 | 96 | 4-7 | 3 | 0.4 |

Key Properties and Advantages

1. Flame Retardancy

Aluminum hydroxide flame retardant decomposes at around 220°C, releasing water vapor that absorbs heat and slows down the combustion process. This heat absorption significantly prevents flame propagation, helping cables meet stringent fire safety standards.

2. Smoke Suppression

The released water vapor not only cools the material but also dilutes combustible gases, effectively reducing smoke emission in cable flame retardant additives. This property is crucial for cables used in public buildings, transportation, and enclosed spaces.

3. Halogen-Free & Environmentally Friendly

Unlike halogen-based flame retardants, ATH does not release toxic or corrosive gases when exposed to fire. This ensures compliance with environmental and safety regulations, making it an ideal option for eco-friendly cable production.

4. Excellent Filler Functionality

Aluminum hydroxide filler acts as both a flame retardant and a filler, improving mechanical properties, reducing material cost, and enhancing cable durability. Its high whiteness also improves the overall appearance of the cable.

5. Improved Dispersion

Surface-modified ATH shows superior dispersion in polymer matrices, allowing for higher loading levels without sacrificing flexibility or mechanical strength. This leads to better overall performance in cable insulation and sheathing materials.

Main Applications in Cables

- LSZH Cables: ATH for LSZH cables is essential for reducing smoke and toxic emissions, commonly used in railways, airports, and data centers.

- PVC Cables: ATH for PVC cables enhances flame retardancy and stability while maintaining flexibility.

- Silicone Rubber Cables: Provides thermal stability and reliable insulation performance.

- Thermoplastic & Thermoset Cables: Suitable for various industrial and power cable applications.

Important Considerations

1. Dosage

The ideal dosage of superfine grade aluminum hydroxide for cables depends on the required flame retardant performance. Typical loading levels range between 150–200 parts per hundred resin (phr) for LSZH compounds.

2. Surface Activation

Activated ATH improves compatibility with polymers, ensuring better dispersion and flame retardant efficiency.

3. Material Compatibility

Before large-scale use, verify that ATH is fully compatible with other cable compound ingredients to avoid processing issues.

Why Choose Our Superfine ATH?

As a professional aluminum hydroxide supplier, we provide:

- High-purity ATH with consistent particle size (1–3 μm)

- Customized surface treatment for better dispersion

- Stable supply and competitive pricing

- Technical support for cable compound formulation

Conclusion

By using Superfine Grade Aluminum Hydroxide for Cables, manufacturers can produce safer, eco-friendly, and high-performance cable products. Whether for LSZH, PVC, or specialized cable types, our ATH offers the reliability and efficiency needed for modern cable production.

Contact us today to get high-quality ATH for your cable applications.