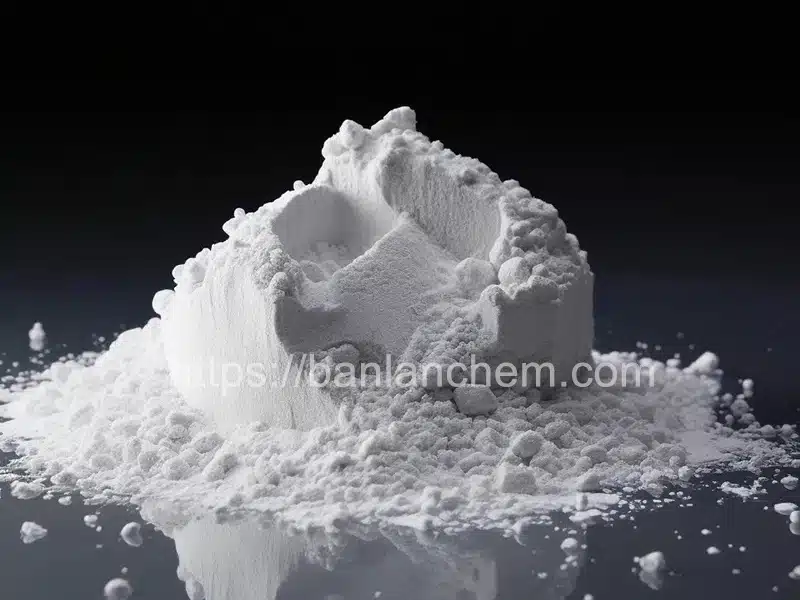

Tabular Alumina is a high-purity alumina (Al2O3) material characterized by its tabular-shaped crystals. Produced through high-temperature sintering, typically above 1900°C, Tabular Alumina possesses outstanding thermal shock resistance, chemical inertness, and mechanical strength. Its unique properties make it a premium refractory and ceramic raw material.

Key Properties of Tabular Alumina

- High Purity: Typically above 99.2% Al₂O₃, minimizing impurities and ensuring superior refractory performance.

- Excellent Thermal Shock Resistance: Withstands rapid temperature changes without cracking.

- High Mechanical Strength: Provides structural integrity under extreme temperatures and conditions.

- Chemical Stability: Resistant to corrosion and reactions with molten metals and slags.

- Low Porosity: Enhances density and durability in refractory applications.

Technical Specifications and Grades

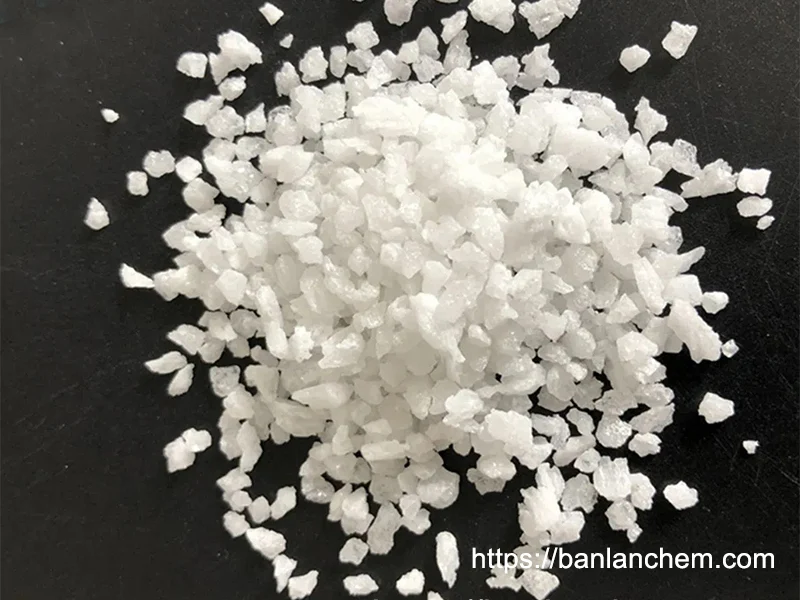

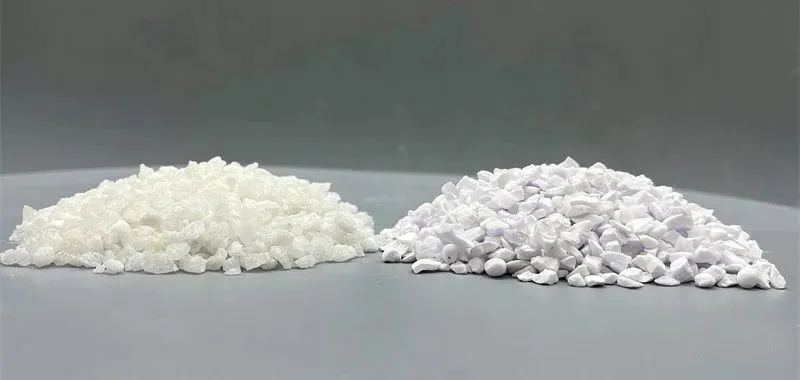

Tabular Alumina is commonly available in various grades and granular sizes tailored to specific applications:

| Property | Typical Value |

|---|---|

| Al₂O₃ Content | ≥ 99.5% |

| Bulk Density | ~3.50 g/cm³ |

| Water Absorption | < 1.5% |

| Sintering Temperature | Approx. 1900°C |

| Particle Sizes | 0–1 mm, 1–3 mm, 3–5 mm, Custom available |

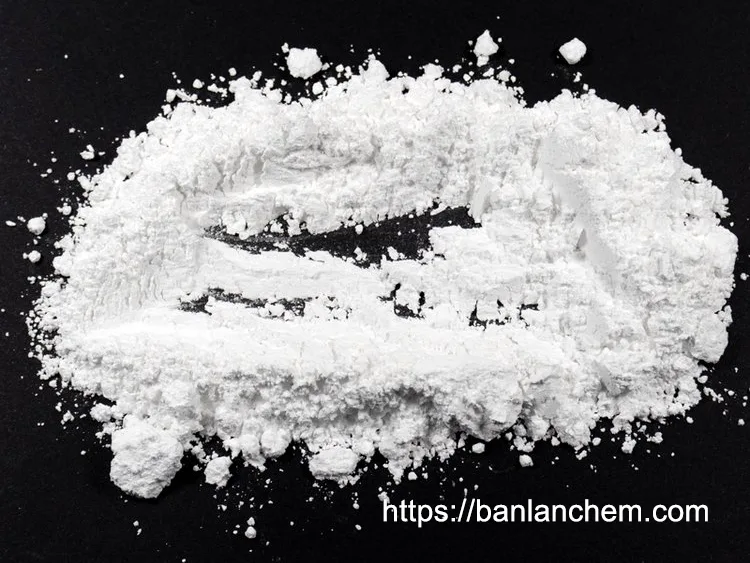

While tabular alumina is known for its high thermal stability and low porosity, calcined alumina polishing is preferred in precision surface treatment due to its fine particle size and high purity.

Application of Tabular Alumina

Due to its excellent properties, Tabular Alumina is widely used across several industries:

- Refractories: Ideal for manufacturing high-quality refractory bricks, castables, kiln furniture, and crucibles.

- Ceramics: Used in advanced ceramics, ceramic rollers, and wear-resistant components.

- Abrasives: Essential in the production of grinding wheels and polishing media.

- Metallurgy: Suitable as protective lining in steel ladles and other metallurgical vessels.

Its superior thermal and mechanical properties enable longer service life and improved performance under extreme conditions.

Banlanchem can customize particle size distribution according to your specific requirements.

Packaging & Delivery

- Standard: 25kg PE-lined bags or 1000kg jumbo bags

- Custom packaging options available upon request

- Secure palletized shipment for global delivery

- Samples available for evaluation

Why Choose Banlanchem as Your Supplier

Banlanchem is your trusted global supplier of high-purity Tabular Alumina, offering:

- Quality Assurance: Strict quality control to guarantee consistent product performance.

- Customized Solutions: Tailored products meeting your specific particle size and purity requirements.

- Reliable Supply: Stable production capabilities ensuring timely delivery worldwide.

- Technical Support: Professional technical advice and customer service to assist your application needs.

Frequently Asked Questions

1. What is Tabular Alumina?

Tabular Alumina is a high-purity sintered form of alumina (Al₂O₃) with a completely crystalline, alpha-phase structure. It is produced at ~1900°C without any sintering aids, making it extremely stable under high temperatures.

Compared to calcined alumina, tabular alumina is produced at even higher temperatures and has a coarser particle size, making it suitable for structural applications where strength and bulk density are required.

2. What are the main applications of Tabular Alumina?

Tabular Alumina is widely used in refractories, ceramics, abrasives, kiln furniture, and foundry materials due to its excellent thermal shock resistance and mechanical strength.

3. How is Tabular Alumina different from Fused Alumina or Calcined Alumina?

Unlike fused alumina, which is melted and quickly cooled, tabular alumina is sintered slowly at very high temperatures. It has no glassy phase, lower porosity, and offers better thermal stability. Compared to calcined alumina, it is denser and more suitable for high-temperature structural applications.

Read more about:What Is the Difference Between Fused Alumina and Tabular Alumina?

4. What particle sizes are available from BanlanChem?

BanlanChem offers a wide range of particle sizes including 0–1 mm, 1–3 mm, 3–5 mm, and custom sizes based on your requirements.

5. Is Tabular Alumina available in bulk packaging?

Yes. We offer packaging options such as 25kg PE-lined bags, 1000kg jumbo bags, and customized packaging for large-volume or export needs.