High Purity Boehmite Powder: From Lithium Battery Safety to Advanced Ceramics

Date: September-15-2025 Categories: News、Aluminium Hydroxide Views: 160

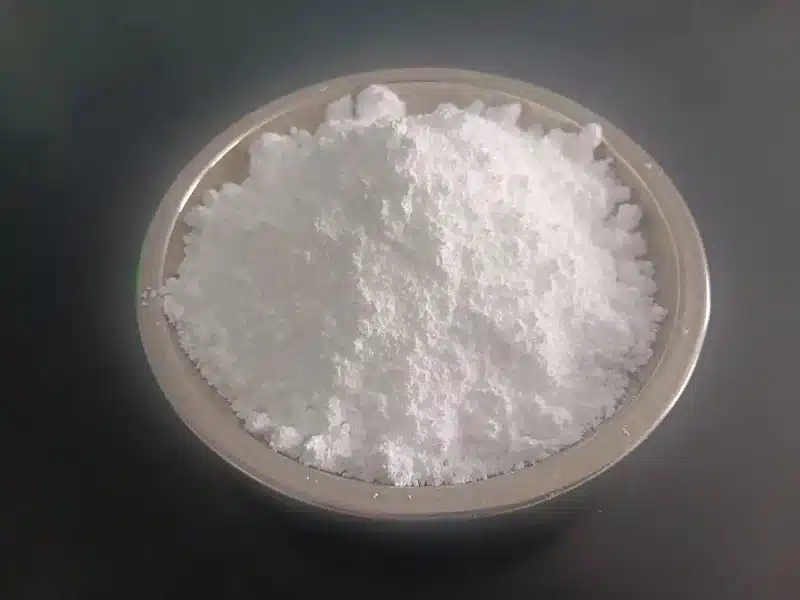

High Purity Boehmite is a layered aluminium oxyhydroxide compound with the formula γ-AlO(OH). Thanks to its unique physical and chemical properties, it is gaining attention across multiple industries. While boehmite occurs naturally, industrial production of high purity boehmite creates new opportunities in electronics, energy storage, and ceramics.

How High Purity Boehmite is Produced

Producing high purity boehmite involves several steps: raw material treatment, synthesis, purification, and drying. Typical precursors include aluminium hydroxide or aluminium salts. Using hydrothermal or similar controlled methods, these precursors react under precise temperature and pressure to form boehmite.

After synthesis, impurities are removed through washing, filtration, and ion-exchange. The resulting product is dried and milled to achieve the desired particle size. Each step is carefully controlled, because purity levels directly affect the performance of the final material.

Why Purity Matters

Even trace impurities can weaken boehmite’s performance in high-tech applications. For example, in electronic materials, impurities may reduce insulation or cause unwanted conductivity. Therefore, the production of high purity boehmite requires strict quality control and advanced purification techniques.

Key Applications of High Purity Boehmite

1. Lithium-Ion Battery Safety

Boehmite is widely used as a coating on battery separators. It enhances heat resistance and mechanical strength, helping to improve battery safety. This makes it valuable in electric vehicles and energy storage systems where safety is critical.

2. Ceramics and Reinforcement

In ceramics, boehmite acts as an additive to improve sintering behavior and increase mechanical strength. It helps manufacturers achieve more durable and reliable ceramic products used in electronics and structural materials.

3. Catalyst Carriers and Special Glass

High purity boehmite is used as a precursor for catalyst carriers due to its ability to transform into γ-alumina with a high surface area. It also plays a role in producing wear-resistant materials and certain types of advanced glass.

How Boehmite Differs from Other Aluminium Compounds

Although boehmite, aluminium hydroxide, and alumina all contain aluminium, their structures and behaviors differ:

- Boehmite: layered structure; when dehydrated, transforms into porous γ-alumina with high surface area.

- Aluminium hydroxide: widely used as a flame retardant filler; decomposes differently under heat.

- Alumina (Al2O3): dense or porous crystalline materials used in ceramics, abrasives and refractories. See our White Fused Alumina.

For a comparison, you can also check What is Alumina Trihydrate (ATH)?

Handling and Storage of High Purity Boehmite

Boehmite powder is generally stable, but it should not be exposed to high humidity for long periods to avoid clumping or property changes. As with other fine powders, protective equipment such as masks and gloves is recommended to ensure safe handling.

Production in Shandong, China

Shandong is one of China’s major industrial hubs. Producers in this region focus on selecting quality raw materials and optimizing processes to balance cost and performance. Some companies are also exploring greener methods, such as reducing water usage and recycling by-products, to minimize environmental impact.

Market Outlook

The demand for high purity boehmite is rising alongside the growth of the new energy and electronics industries. Different applications require specific purity levels, particle sizes, and morphologies, so producers must tailor their processes to customer needs.

Pricing is influenced by raw materials, energy consumption, and purification requirements. High purity boehmite typically costs tens of thousands of RMB per ton, depending on grade and market demand.

Future Development

Research is focused on more efficient synthesis methods, higher purity and consistency, and new applications. In energy storage, boehmite-based materials may contribute to next-generation batteries. Sustainable production—reducing energy use and waste—is also a major trend.

Conclusion

High purity boehmite is a functional material with wide-ranging applications in energy, ceramics, and advanced materials. Its production and use require expertise in materials science and chemical engineering. Ongoing innovation will continue to unlock its potential in the global market.

Related reading: Surface Modification of Aluminum Hydroxide Powder · Dried vs Wet Aluminum Hydroxide