Tabular Alumina Supplier – Uses and Properties Explained

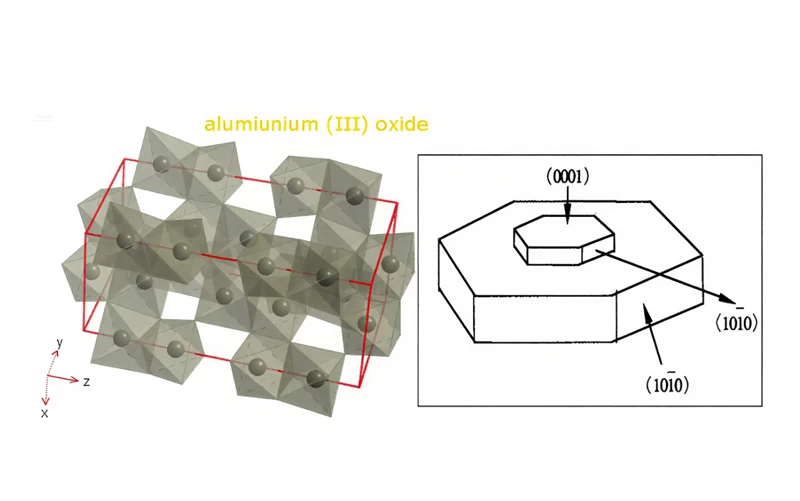

Alumina (Al2O3) comes in many forms. Like other metal oxides, it has high hardness, a high melting point, strong mechanical properties, and excellent resistance to corrosion and oxidation. If you're looking for a reliable tabular alumina supplier, it's important to understand these fundamental properties, as they determine the material's suitability for various high-performance applications.

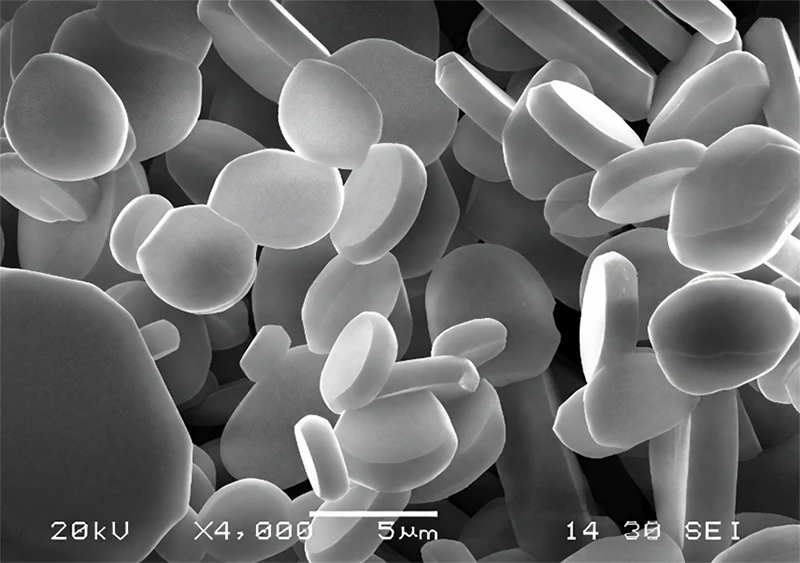

Tabular alumina is a special kind of alumina. It has a unique plate-like (flat, wide) crystal structure that gives it characteristics of both micron-scale powders and nanomaterials. It belongs to the α-Al2O3 category and typically has a grain diameter of 5–50 μm and a thickness of 100–500 nm. Some grains even display well-formed hexagonal shapes.

1. Abrasives and Polishing Slurries

In industries that involve polishing or grinding, alumina (also known as corundum) is popular due to its high Mohs hardness of 9. Tabular alumina, compared to conventional nano-alumina, has a smooth, flat surface that causes less scratching to delicate items like semiconductor wafers and smartphone casings.

This feature can increase the yield of finished products by 10–15%. As a result, tabular alumina is now widely used in electronics, gemstone processing, and metal-ceramic industries.

2. Pearlescent Pigments

Natural mica is commonly used in pearlescent pigments, but it often contains colored impurities and uneven thickness, which can reduce visual quality.

Tabular alumina, being synthetic, offers superior purity, consistent thickness, a high aspect ratio, and a smooth surface. It also disperses well in water. When coated with metal oxides like TiO2 or Fe2O3, it becomes an excellent base for high-quality pearlescent pigments. These pigments require less colorant to achieve similar visual effects compared to mica-based ones.

3. Cosmetics

Tabular alumina is stable, odorless, non-toxic, and nearly colorless. Thanks to its small size, thin layers, and smooth surface, it works well in cosmetics, enhancing brightness and giving products a soft, smooth feel on the skin.

It also helps makeup stay in place longer by reducing smudging from oil or sweat and improves how well the product spreads and adheres to the skin.

4. Functional Coatings

Tabular alumina doesn’t clump easily and bonds well with other fine powders, making it suitable for advanced functional coatings. For example, stealth aircraft use coatings containing it to absorb radar signals.

It also supports UV-blocking and photocatalytic coatings, making it useful in solar panel layers and other protective films.

5. Inorganic Fillers

Tabular alumina has been used as a filler to improve the thermal conductivity of polymers. It offers much higher thermal conductivity than organic polymers. When added to polymers, it forms heat pathways that carry heat away from electronic components.

The larger the particle size, the fewer connection points are needed, which enhances heat transfer and helps electronic devices last longer.

6. Toughening Agent in Ceramics

Adding tabular alumina to ceramic materials helps prevent cracks by deflecting them and reinforcing weak areas. Under hot-pressing conditions, it can produce alumina ceramics with a fracture strength of 600 MPa and toughness of 7.9 MPa·m1/2.

Other ceramics also benefit. For example, adding 28 vol % of tabular alumina to X-sialon increases toughness from 1.77 to 4.16 MPa·m1/2. In TiO2, adding 30 vol % increases fracture toughness from 2.4 to 3.3 MPa·m1/2 and fracture strength from 215 to 265 MPa.

Overall, tabular alumina is a highly versatile material. Thanks to its unique shape and excellent properties, it plays a crucial role in modern industries ranging from electronics to ceramics, cosmetics, and coatings.

The Evolution and Broad Applications of Tabular Alumina

Tabular Alumina, a unique material that has undergone years of research and development, now shows promise for a wide variety of applications. Its lack of agglomeration, strong adhesion, and easy compatibility with functional micronized powders enable the preparation of many new functional coating films that play a crucial role across industries.

When sourcing this material, working with a reliable tabular alumina supplier ensures consistent quality, tailored particle size, and technical support needed to meet the demands of advanced coating technologies.