Alumina powder (Al₂O₃) is a fine white material widely used in ceramics, polishing, refractories, and electronic applications. BanlanChem — a trusted Alumina Powder Manufacturer and Supplier from China — provides high-purity, consistent, and customizable alumina grades for industrial production. Whether you need it for polishing, coatings, or catalysts, our factory ensures stable supply and competitive wholesale prices worldwide.

Table of Contents

- 1. What Is Alumina Powder?

- 2. Key Properties and Features

- 3. Main Types of Alumina Powder

- 4. Applications of Alumina Powder

- 5. Production and Processing

- 6. Why Choose BanlanChem Factory

- 7. Technical Specifications

- 8. FAQ – Common Questions About Alumina Powder

- 9. Related Products and Articles

1. What Is Alumina Powder?

Alumina powder, also called aluminum oxide powder, is a fine, white, odorless material derived from bauxite or aluminum hydroxide. It is known for its high hardness, thermal stability, and electrical insulation. Due to these characteristics, alumina powder is a key raw material in modern industries.

- Chemical formula: Al₂O₃

- Appearance: white fine powder

- Purity: typically 99%–99.99%

- Crystal phases: α (alpha), γ (gamma), δ (delta), etc.

BanlanChem’s Alumina Powder Factory offers various grades including Calcined Alumina, Tabular Alumina, and White Fused Alumina, meeting global industrial demands.

Alumina powder, also known as aluminum oxide (Al₂O₃), is a high-purity industrial material used in ceramics, refractories, and polishing applications. For detailed chemical data on Aluminum Oxide (Al₂O₃), refer to the PubChem database.

2. Key Properties and Features

Alumina powder is widely chosen for its outstanding physical and chemical stability. Below are its core features:

- High hardness (Mohs 9) and excellent wear resistance.

- Good thermal conductivity and high-temperature stability.

- Electrical insulation with high dielectric strength.

- Chemically inert to most acids and alkalis.

- Low impurity content and high whiteness.

- Controllable particle size and narrow distribution.

These properties make it ideal for advanced ceramics, refractory materials, abrasives, and catalysts.

3. Main Types of Alumina Powder

Depending on production and calcination methods, alumina powder can be divided into several types:

- α-Alumina (Alpha Alumina): High-density, hard, thermally stable — used in ceramics, abrasives, and refractories.

- γ-Alumina (Gamma Alumina): High surface area, excellent adsorption — ideal for catalysts and adsorbents.

- δ/θ-Alumina: Intermediate transition phases used in coatings and catalytic supports.

- Activated Alumina: Porous structure, strong absorption — used in gas drying and water purification.

- Tabular Alumina: Sintered α-Al₂O₃ with large crystals and high strength for refractories.

BanlanChem offers all these types as an experienced Alumina Powder Supplier and Wholesale Factory in China.

4. Applications of Alumina Powder

Because of its exceptional versatility, alumina powder is widely used in different industries. Below are the most common applications:

Ceramics and Refractories

Used as a raw material for high-alumina ceramics, crucibles, and kiln linings. It provides strength, hardness, and thermal stability.

Polishing and Surface Finishing

Fine-grain alumina powder is an ideal abrasive for Calcined Alumina Polishing — offering smooth finishes for metals, glass, and semiconductors.

Catalysts and Adsorbents

γ-Al₂O₃ powder is used as a support for catalysts in petrochemical and environmental processes, as well as in desiccant materials.

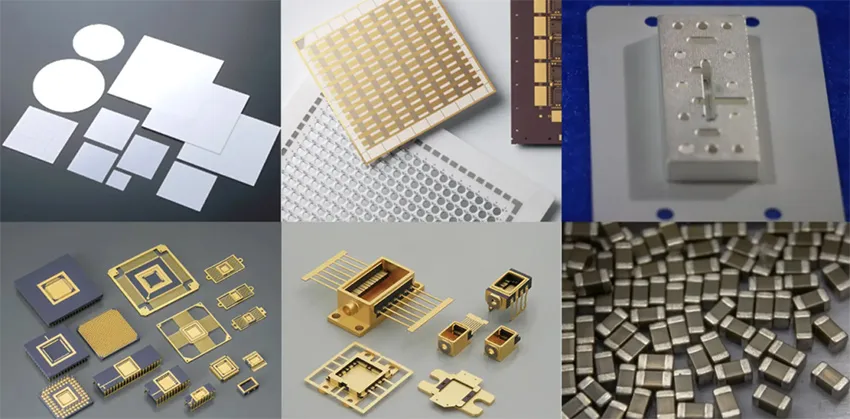

Electronic and Coating Materials

Due to its insulation and heat resistance, alumina powder is used in electronic components, thermal coatings, and conductive pastes.

Filler and Additives

Serves as a functional filler in plastics, rubbers, and paints, improving thermal and mechanical properties.

Learn more about alumina powder uses across ceramics, refractories, polishing, and electronics industries.

5. Production and Processing

BanlanChem’s Alumina Powder Factory uses advanced calcination and grinding processes to achieve stable particle size and high purity.

Production Process

- Bayer process or chemical precipitation to obtain aluminum hydroxide.

- Calcination at high temperatures (400°C–1800°C) to remove water and control crystal structure.

- Grinding and classification to achieve target particle sizes.

- Screening and packaging under dust-free environment.

Quality Control

- Strict impurity detection (Na₂O, SiO₂, Fe₂O₃, moisture).

- Particle size and BET surface area testing.

- Consistent whiteness and purity control.

- Batch traceability and COA certification.

6. Why Choose BanlanChem Factory

As a professional Alumina Powder Manufacturer and Supplier in China, BanlanChem provides complete solutions from production to global logistics.

- Factory-direct pricing for OEM & wholesale customers.

- Full customization of particle size and purity levels.

- High production capacity and stable supply chain.

- Export experience to 30+ countries worldwide.

- Fast delivery and reliable technical support.

BanlanChem focuses on high-purity alumina products for industries such as ceramics, polishing, catalysts, and electronics. Learn more about our Aluminum Hydroxide and Boehmite Alumina Powder — both essential raw materials for alumina production.

7. Technical Specifications of Alumina powder

The physicochemical index standards:Q/CHALCO-SD A016-2012

Activated alumina Powder is produced by activation roasting process, with hydraulical property, mainly used for refractory castable, advanced ceramic binder, catalyst support, and medical absorbent and specific catalysts. The main crystal phases include X-ρ, and γ-phase alumina.

| crystal phases | Chemical composition % | BETm2/g≥ | Pore Volume ml/g≥ | Crushing strengthN/Pieceμm | ||||

| Al2O3≥ | SiO2≤ | Fe2O3≤ | Na2O≤ | L.O.I≤ | ||||

| ρ-AO | 60* | 0.05 | 0.02 | 0.40 | ≤10 | 180 | 0.16 | 8-12 |

| γ-AO | 92 | 0.10 | 0.05 | 0.70 | 6 | — | — | — |

| *Comment:60 is for theρ-Al2O3 composition | ||||||||

If you are willing to wholesale quality, advanced and durable activated alumina powder from one of the famous China activated alumina powder manufacturers, BANLANCHEM is always at your service.

Customized specifications are available for OEM and wholesale buyers. Contact BanlanChem Factory for tailored alumina powder grades.

8. FAQ – Common Questions About Alumina Powder

1. What is alumina powder?

Ans: Alumina powder, also known as aluminum oxide powder, is a compound composed of aluminum and oxygen with the chemical formula Al2O3. It is a versatile material with various industrial applications.

2. What are the common uses of alumina powder?

Ans: Alumina powder is used in a wide range of applications, including ceramics, electronics, abrasives, refractories, catalysts, and as a filler in various materials.

4. How is alumina produced?

Ans: Purity levels can vary, but high-purity grades are often used in critical applications. Purity is typically expressed as a percentage of Al2O3 content.

4. How is alumina powder produced?

Ans: Alumina powder is commonly produced through the Bayer process, which involves extracting alumina from bauxite ore. Other methods include the thermal decomposition of aluminum hydroxide.

5. How should alumina powder be stored?

Ans: Alumina powder is generally not hygroscopic, but it is advisable to store it in a dry place to prevent moisture absorption. Proper labeling and adherence to safety guidelines are also recommended.

6. Can alumina powder be used as a catalyst?

Ans: Yes, certain forms of alumina exhibit catalytic activity and are used in catalyst applications.

7. Are there safety considerations when handling alumina powder?

Ans: Users should follow safety guidelines provided by manufacturers. Dust inhalation should be minimized, and appropriate personal protective equipment should be used.

8. What is the particle size of alumina powder?

Ans: The particle size of alumina powder can vary depending on the manufacturing process and specific requirements. It is often available in fine powders with a range of particle sizes.

9. Can alumina powder conduct electricity?

Ans: No, alumina is an electrical insulator. It has high dielectric strength and is widely used in electrical insulating applications.

10. Is alumina powder resistant to corrosion?

Ans: Yes, alumina is chemically inert and resistant to corrosion, enhancing its durability in various environments.

11. What is the melting point of alumina?

Ans: Alumina has a very high melting point, approximately 2,072 degrees Celsius (3,762 degrees Fahrenheit).

12. Can alumina powder be sintered?

Ans: Yes, alumina powder can be sintered to form dense, strong ceramics. This property is valuable in the production of ceramics and refractories.

13. Does alumina powder have abrasive properties?

Ans: Yes, alumina is known for its hardness and abrasion resistance, making it suitable for use in abrasive applications.

14. Are there different types of alumina powder?

Ans: Yes, there are various types of alumina powder with different properties, such as calcined alumina, reactive alumina, and tabular alumina, each tailored for specific applications.

15. Is alumina powder transparent?

Ans: In its transparent or translucent forms, alumina can be used in optical applications.

16. Is alumina powder safe for food or pharmaceutical applications?

Ans: Only specific grades of alumina are suitable for such uses. Always confirm with the supplier whether the powder meets food or pharmaceutical-grade standards.

17. What packaging options are available for alumina powder?

Ans: Alumina powder can be supplied in sealed bags, drums, or custom bulk packaging to meet different industrial needs.

18. Can alumina powder be customized based on application?

Ans: Yes, particle size, phase composition, and purity can be tailored based on the customer’s specific requirements.

19. What is the shelf life of alumina powder?

Ans: When stored properly in dry, cool conditions, alumina powder maintains its quality for several years without significant degradation.

20. Does alumina powder react with acids or bases?

Ans: Alumina is generally inert but may slowly react with strong acids or bases at high temperatures.

Interested in our Alumina powder? Contact us today to get a quote, sample, or technical datasheet.