Boehmite is an aluminum oxyhydroxide with the chemical formula AlOOH. It is also called alumina monohydrate. Boehmite is used in batteries, flame retardant systems, catalysts, coatings, ceramics, and more. At BanlanChem, we supply Boehmite as dry powder, surface-treated grades, or water-based slurry. We support Manufacturer, Supplier, Factory and Wholesale cooperation.

This page explains what Boehmite is, how it works, and where it is used. It is written in simple language for engineers, buyers, and distributors.

What Is Boehmite?

- Name: Boehmite

- Formula: AlOOH

- Also called: Alumina Monohydrate

- Main uses: Battery separator coating, flame retardant filler, catalyst support, coatings, ceramics

- Available forms: Dry powder, surface-treated powder, water-based slurry

In simple terms, Boehmite is a special aluminum-based material. It has a stable structure and a high surface area (especially nano Boehmite). It can improve safety, thermal resistance, and performance in many industrial systems.

Boehmite Powder Specifications:

| ItemBrands | Chemical components % | Physical performance | |||||||

| SiO2≤ | Fe2O3≤ | Na2O≤ | Moisture | L.O.I≤ | Gelationindex% | Al2O3·3H2O% | Porevolumeml/g | BET m2/g≥ | |

| P-G-03 | 0.30 | 0.03 | 0.30 | — | 24 | ≥95 | ≤5 | ≥0.3 | 250 |

| P-D-03 | 0.30 | 0.03 | 0.30 | ≤25 | 24 | ≥95 | ≤5 | ≥0.3 | 250 |

| P-DF-03 | 0.30 | 0.03 | 0.30 | ≤20 | 24 | ≥95 | ≤5 | ≥0.3 | 250 |

| P-DF-03-LS | 0.03 | 0.10 | - | - | - | ≥95 | 5 | ≥0.3 | 250 |

| Chemical composition % | |

| Fe2O3 | ≤0.04 |

| Na2O | ≤0.2 |

| moisture | ≤0.5 |

| Physical performance | |

| L.O.I | ≤17 |

| D50(μm) | 2.0±0.5 |

| BET(m2/g) | ≥70 |

| bulk density(g/cm3) | 0.3-0.5 |

A-AS-HC-GSA Boehmite is an important precursor for the preparation of γ-Al2O3 and α-Al2O3, mainly used in catalyst and its carrier materials, coating material, porous membranes and soft abrasive, high temperature ceramics etc.

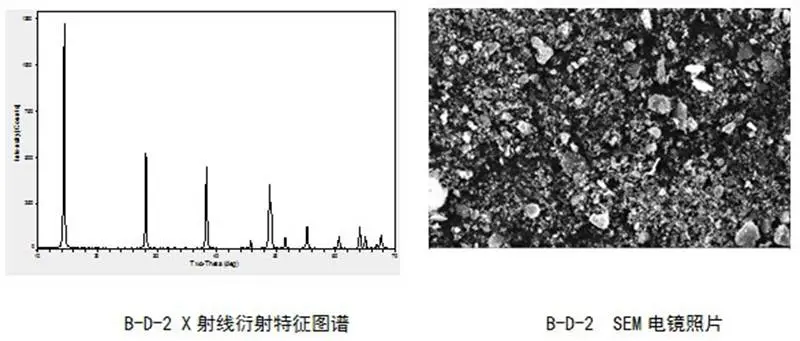

Chemical Nature & Structure

Boehmite is an aluminum oxyhydroxide. Its structure contains oxygen and hydroxyl groups (O–H). It is often identified by XRD features (for example, some labs reference JCPDS card patterns for phase checking). Boehmite can exist in orthorhombic or related metastable structures depending on synthesis and conditions.

A key feature is its phase transformation. When heated in the range of about 400–700°C, Boehmite converts into alumina (Al2O3). This is important for ceramics, catalysts, and high-temperature applications.

If you also work with alumina products, you may want to review our related product pages: Calcined Alumina.

Key Properties

Many industries choose Boehmite because it offers a strong balance of thermal, surface, and processing properties. Below are the main advantages in simple terms.

- High thermal stability: stays stable in harsh conditions (often used in systems around 300°C).

- High surface area (nano grades): helps adhesion, coating uniformity, and reaction activity.

- Narrow pore distribution: supports controlled coating and stable performance.

- Good dispersibility: mixes well in many polymer, solvent, or water-based systems.

- Low water absorption: helps storage and processing in some formulations.

- Scratch resistance contribution: can improve surface durability in coatings.

- High purity options: suitable for high-end technical applications.

Typical nano Boehmite particle size may be around 20–50 nm. Sub-micron and micron grades are also available for different uses.

For users comparing different alumina derivatives, we also have a detailed discussion on the difference between boehmite and pseudo-boehmite , highlighting key structural, performance, and application distinctions.

Manufacturing & Particle Control

As a Boehmite manufacturer and factory partner, we focus on stable quality and particle control. Industrial production often uses:

- Hydrothermal ageing (from aluminum hydroxide)

- Sol-gel methods

- Precipitation processes

- Spray drying for powder shaping

Modern processes can control particle size from about 0.2 µm to 6 µm for sub-micron products. Nano Boehmite can be made for high surface area and better coating performance.

Some emerging “green” synthesis approaches use reactive aluminum alloys with water to produce Boehmite quickly and allow raw material recycling in large-scale systems. (Production routes may differ by plant design and customer requirements.)

Product Forms & Options

To fit different industries, Boehmite can be supplied in several forms. Choose the form based on your process, dispersion method, and final product requirements.

- Dry powder: easy to ship and store, used in polymer compounding, coatings, and catalysts.

- Surface-treated powder: improved compatibility with specific resins or solvents.

- Water-based slurry: suitable for coating systems, including battery separator coatings.

For OEM/ODM projects, we can discuss target particle size, surface area range, and surface treatment needs.

Boehmite Applications

Boehmite is widely used across energy, materials, and chemical industries due to its thermal stability, surface properties, and compatibility with different systems.

1. Lithium-Ion Batteries

- Separator coating material (LIBS)

- Improves thermal resistance and battery safety

- Reduces shrinkage and short-circuit risk at high temperature

- Used in both powder and slurry form

2. Halogen-Free Flame Retardant Systems

- Functional filler for polymers and composites

- Common in cables, electronics, and PCB materials

- Works synergistically with phosphorus-nitrogen systems

- Supports eco-friendly and halogen-free formulations

3. Catalysts & Catalyst Supports

- Used directly as catalyst material

- Precursor for alumina catalyst supports

- High surface area helps metal dispersion

- Applied in petrochemical and fine chemical processes

4. Coatings & Surface Treatments

- Improves scratch resistance and surface durability

- Used in automotive and industrial coatings

- Enhances matting and surface control

- Suitable for water-based and solvent-based systems

5. Ceramics & Refractory Materials

- Alumina precursor for ceramic production

- Supports controlled phase transformation to Al₂O₃

- Used in technical ceramics and insulation components

6. Pigments & Functional Fillers

- Helps improve dispersion and stability

- Used in ceramic pigments and specialty fillers

- Enhances mechanical and surface performance

7. Water Treatment (Research & Industrial Use)

- Nano boehmite used as adsorbent material

- Studied for removal of heavy metals and dyes

- Applied in wastewater and environmental research

8. Biomedical & Advanced Materials (Research Level)

- Investigated for drug delivery carriers

- Studied for controlled release systems

- Mainly used in laboratory and R&D environments

Boehmite for Lithium-Ion Batteries

Battery safety is a major reason why Boehmite is used in lithium-ion systems. Boehmite can be applied as a coating material on battery separators (often called LIBS separator coating). It helps improve thermal stability and reduce the risk of internal short circuits.

- Improves separator heat resistance

- Helps maintain structure at higher temperatures

- Supports stable coating and better safety performance

If your project needs a slurry form or a specific particle size for coating, tell us your coating method and binder system. We can recommend a suitable Boehmite grade.

Boehmite for Halogen-Free Flame Retardant

Boehmite is widely used as a halogen-free filler in flame retardant systems. It is used in high-performance polymers, cable compounds, and printed circuit board (PCB) materials. It can work with phosphorus-nitrogen systems to improve processing and performance.

- Helps improve flame resistance in eco-friendly formulations

- Supports compliance-focused material design (halogen-free direction)

- Useful in high-performance polymer and PCB applications

For related aluminum hydroxide solutions, you may also check: Aluminum Hydroxide Powder.

Boehmite for Catalysts & Supports

In catalysis, Boehmite can be used directly or as a precursor to alumina. It is also used as a support material for metal catalysts. A high surface area and stable structure can help create good dispersion of active metals.

- Used in petroleum and chemical catalyst systems

- Can serve as a carrier/support for metal catalysts

- Can transform into alumina at high temperatures for stable catalyst structures

Boehmite for Coatings, Ceramics & Pigments

Boehmite is used in coatings to improve surface performance. It may help enhance scratch resistance and durability. It is also used in ceramics and pigment systems where controlled alumina formation matters.

- Automotive and industrial coatings

- Hydrophobic gelcoat systems (marine and sanitary products)

- Ceramic pigments and ceramic components

- Electrical and thermal insulation parts

Boehmite’s role in coatings and ceramics can vary with purity and particle size. Learn more about this in our article on high purity boehmite powder , from battery safety applications to advanced ceramic materials.

Water Treatment & Biomedical Research

Nano Boehmite has been studied as an adsorbent for water treatment. It can help remove certain pollutants such as Cr(VI), nitrates, and dye molecules in lab studies.

In biomedical research, Boehmite has been explored as a material for controlled drug release systems. These are research areas and may depend on regulatory and application requirements.

Safety, Environment & Handling

Boehmite is generally considered a low-hazard inorganic material. It does not contain halogens and is often described as eco-friendly in many industrial uses. Handling is usually standard for fine powders:

- Use dust control and local ventilation

- Wear protective gloves and safety glasses

- Store in a dry place and keep the package sealed

Disposal and handling requirements can vary by region and by customer standards. We can provide supporting documents and guidance for your market.

Why Choose BanlanChem?

BanlanChem is a Boehmite supplier and Boehmite manufacturer serving global customers. We focus on stable quality, consistent supply, and technical support.

- Factory supply: stable production and shipment planning

- OEM/ODM: particle size targets, surface treatment, slurry options

- Wholesale support: bulk supply for distributors and large users

- Application support: battery, flame retardant, catalyst, and coating guidance

If you want more background reading, you may also like: our technical articles and news.

FAQ

Is Boehmite the same as alumina?

No. Boehmite is AlOOH (alumina monohydrate). Alumina is Al2O3. Boehmite can transform into alumina when heated (often around 400–700°C).

What particle sizes can Boehmite be supplied in?

Boehmite can be supplied as nano grades (often around 20–50 nm) and also sub-micron to micron grades (e.g., about 0.2 µm to 6 µm) depending on the application.

Which Boehmite form is best for battery separator coating?

Many separator coating systems use Boehmite slurry or a powder designed for easy dispersion. The best choice depends on your binder, solvent/water system, coating thickness, and drying conditions.

Can I buy Boehmite in bulk for wholesale?

Yes. We support wholesale Boehmite supply for distributors and industrial users. Contact us with your annual demand and target specifications.

Do you support OEM/ODM Boehmite products?

Yes. As a Boehmite factory partner, we support OEM/ODM services, including particle size control, surface modification, and slurry development.

Request a Quote

If you need Boehmite for batteries, flame retardant systems, catalysts, or coatings, please contact BanlanChem.

- Tell us: application, form (powder / treated / slurry), target particle size, and quantity

- Get: recommended grade, specification proposal, and quotation

- Support: OEM/ODM development and wholesale supply