Click below to navigate this page:

Table of Contents

- Product Introduction

- Key Features & Advantages of aluminum hydroxide ATH

- Technical Specifications

- Applications

- Why Choose BanlanChem

- Packaging & Storage

- FAQ

- Related Products

- Contact & Get a Quote

Product Introduction of Aluminum Hydroxide ATH

High Whiteness Aluminum Hydroxide ATH, also known as High Whiteness Alumina Trihydrate (ATH) or Hydrated Alumina, is a fine white powder with high purity, non-toxicity, and good fluidity. It remains stable under normal temperature and decomposes into Alumina (Al₂O₃) when heated.

ATH features excellent brightness and whiteness. It is widely used as a functional filler in plastics, rubbers, artificial marble, onyx, coatings, toothpaste, and paper. It provides smoke suppression, prevents dripping, and releases no toxic or corrosive gases when exposed to heat.

- Synonyms: Aluminium hydrate, Alumina trihydrate, Hydrated alumina

- CAS No.: 21645-51-2

- Chemical Formula: Al(OH)3

Key Features & Advantages of Aluminum Hydroxide ATH

- High Whiteness (≥97%) – Brighter and cleaner end products

- Excellent Thermal Stability – Strong flame resistance and thermal protection

- High Purity (≥99.5%) – Consistent performance across batches

- Low Oil Absorption – Improves dispersion and surface finish

- Custom Particle Sizes – From 1–25 µm or as requested

- Halogen-Free and Eco-Friendly – Non-toxic, sustainable flame retardant

Technical Specifications of Aluminum Hydroxide ATH

BanlanChem’s High Whiteness Aluminum Hydroxide is produced by a seeding precipitation process using sodium aluminate solution from the sintering route. This method results in slow decomposition, complete crystallization, low impurity levels, and high transparency.

High whiteness aluminum hydroxide ATH for filler (Seeding process)

It is produced by precipitaion method with the sodium aluminate solution from sintering process as the seeds, its characteristics – Slow decomposition rate, complete crystallization, low impurity, high intensity and good transparency.

It has the texture properties of jade, which can be used as superior filler in the solid surface, crafts and other composites.

| Brand | Chemical composition(%) | DOP | Whiteness | Particle size | Moisture | |||||

| Al(OH)3≥ | SiO2≤ | Fe2O3≤ | Na2O≤ | Na2O (S)≤ | ml/100g≤ | %≥ | D50μm | +325mesh≤ | %≤ | |

| H-WF-14SP | 99.6 | 0.03 | 0.02 | 0.20 | 0.02 | 30 | 95 | 16±3 | 12 | 0.3 |

| H-WF-25SP | 99.6 | 0.03 | 0.02 | 0.20 | 0. | 30 | 94 | 25±5 | – | 0.2 |

| H-WF-25MSP | 99.6 | 0.03 | 0.02 | 0.20 | 0.03 | 21 | 95 | – | – | 0.2 |

| H-WF-50SP | 99.6 | 0.03 | 0.02 | 0.20 | 0.02 | 30 | 93 | 50±10 | – | 0.2 |

| H-WF-75SP | 99.6 | 0.03 | 0.02 | 0.20 | 0.02 | 30 | 92 | 85±15 | – | 0.1 |

| H-WF-90SP | 99.6 | 0.03 | 0.02 | 0.20 | 0.02 | 30 | 91 | 95±20 | – | 0.1 |

High whiteness aluminum hydroxide ATH for filler (Carbonating process)

High whiteness(Reputated as China White), low oil absorption, good stability at room temperature and dehydrated to alumina while heating, to make the products have the function of flame retardant. Its a good flame retardant filler because that no toxic and corrosive gases were generated in thermal decomposition.It’s widely used in the solid surface, mould plastics, epoxy potting compound and other composite materials.

| Brand | Chemical composition(%) | DOP | Whiteness | Particle size | Moisture | |||||

| Al(OH)3≥ | SiO2≤ | Fe2O3≤ | Na2O≤ | Na2O(s)≤ | ml/100g≤ | %≥ | D50μm | +325mesh≤ | %≤ | |

| H-WF-8 | 99.6 | 0.05 | 0.02 | 0.30 | 0.03 | 33 | 96 | 8±2 | 3 | 0.4 |

| H-WF-10 | 99.6 | 0.05 | 0.02 | 0.30 | 0.03 | 33 | 96 | 10±2 | 4 | 0.3 |

| H-WF-14G | 99.6 | 0.05 | 0.02 | 0.30 | – | 30 | 90 | 11±3 | – | 0.3 |

| H-WF-14LV | 99.6 | 0.05 | 0.02 | 0.30 | 0.03 | 29 | 95 | 13±3 | 15 | 0.3 |

| H-WF-14 | 99.6 | 0.05 | 0.02 | 0.30 | 0.03 | 32 | 95 | 15±3 | 15 | 0.3 |

| H-WF-15A | 99.6 | 0.04 | 0.01 | 0.20 | 0.03 | 32 | 98 | 13±2 | – | 0.3 |

| H-WF-25 | 99.6 | 0.05 | 0.02 | 0.30 | 0.03 | 32 | 95 | 25±5 | – | 0.2 |

| H-WF-75 | 99.6 | 0.05 | 0.02 | 0.25 | 0.03 | 40 | 93 | 85±15 | – | 0.1 |

| H-WF-90 | 99.6 | 0.05 | 0.02 | 0.25 | 0.02 | 40 | 93 | 100±20 | – | 0.1 |

| H-WF-100 | 99.6 | 0.1 | 0.02 | 0.30 | – | 40 | 90 | ≥90 | – | 0.1 |

The powder has a jade-like texture and can be used as a superior filler in solid surfaces, artificial marble, composite materials, and engineered stone. It offers good dispersibility and thermal stability, making it suitable for demanding industrial applications.

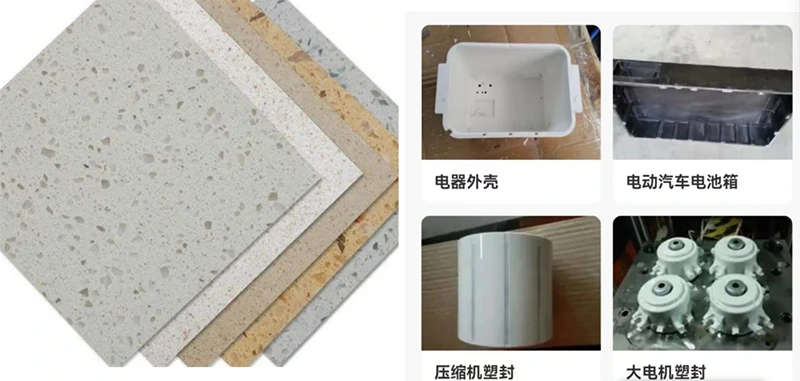

Applications of High Whiteness Aluminum Hydroxide ATH for Filler

1. Plastics & Polymers

ATH acts as a flame-retardant and smoke-suppressant filler in thermoplastics and thermosets. It enhances surface smoothness, brightness, and strength. Common uses include wire and cable insulation, automotive parts, and electrical housings that require strict fire safety standards.

2. Coatings & Paints

In coatings and paints, ATH provides fire resistance and color brightness. It enhances surface quality, reduces smoke, and improves the finish of architectural, marine, and industrial coatings.

3. Rubber Industry

In the rubber sector, ATH serves as a reinforcing and flame-retardant filler. It increases tensile strength, elasticity, and resistance to thermal aging. It is widely used in conveyor belts, gaskets, tires, and hoses.

4. Adhesives & Sealants

ATH offers flame resistance and mechanical durability in construction adhesives, insulation sealants, and electrical bonding compounds. It enables products to meet high fire-safety standards.

5. Other Industrial Applications

- Electrical Cables: Acts as a flame-retardant and smoke suppressant.

- Electronics: Enhances thermal dissipation and flame resistance in housings.

- Composites: Strengthens and protects engineered materials from heat and fire.

- Building Materials: Adds brightness and stability to artificial marble and panels.

Learn more: What is Alumina Trihydrate (ATH)?

Why Choose BanlanChem

- ISO-Certified Manufacturing with Strict Quality Control

- Superior Whiteness for High-Value End Products

- Custom Particle Size, Packaging, and Technical Support

- Reliable Supply Chain to Over 30 Countries

- Competitive Wholesale Pricing for Global Clients

BanlanChem specializes in Aluminum Hydroxide and Alumina Materials for fillers, flame retardants, and catalysts.

Packaging & Storage of High Whiteness Aluminum Hydroxide ATH for Filler

- Available in 25kg / 50kg / 1000kg jumbo bags (24MT per container)

- Store in a cool, dry place and avoid stacking more than 15 bags

- Keep sealed to maintain flowability and whiteness

FAQ

Q1: What is the CAS number of High Whiteness Aluminum Hydroxide?

A: CAS No. 21645-51-2

Q2: What industries use High Whiteness ATH?

A: Plastics, paints, rubber, adhesives, and electronics.

Q3: What particle sizes are available?

A: From 1 µm to 25 µm, or customized on request.

Q4: Is it flame-retardant?

A: Yes. It is halogen-free and offers excellent flame and thermal resistance.

Related Products

- Calcined Alumina – High-purity alumina for ceramics and refractory use.

- Pseudo Boehmite – High surface area for catalysts and adsorbents.

- Low Sodium Calcined Alumina – For electronics and precision ceramics.

- Activated Alumina – Excellent for adsorption and catalysis.

Contact & Get a Quote

Looking for High Whiteness Aluminum Hydroxide ATH? Contact BanlanChem for pricing, samples, or custom specifications. We help you achieve brighter, stronger, and flame-retardant products.