White Fused Alumina and Brown Fused Alumina: Differences, Uses & Prices

Date: July-17-2025 Categories: Products、Alumina、News Views: 223

Introduction

White Fused Alumina and Brown Fused Alumina are important abrasive and refractory materials. Although similar, they differ in several key ways, including raw materials, characteristics, and uses.

How They Are Made

White Fused Alumina(WFA)

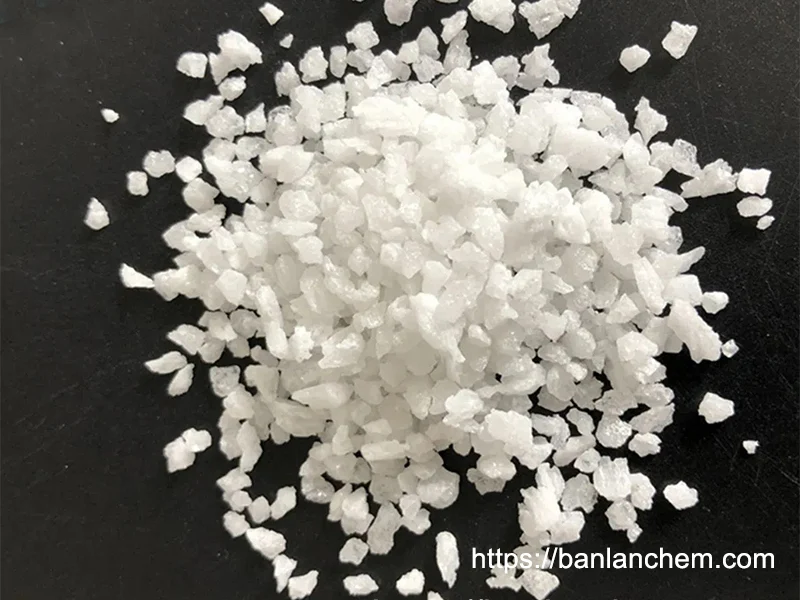

White fused alumina is produced from high-purity alumina powder. It’s melted at high temperatures and cooled quickly to form white crystals with minimal impurities.

Brown Fused Alumina(BFA)

Brown fused alumina is made from bauxite, coal, and iron filings. These materials are melted together at very high temperatures in an electric furnace. The impurities give it its brown color.

White Fused Alumina and Brown Fused Alumina Chemical Composition

White fused alumina has a purity of over 99% alumina, with almost no impurities. This high purity gives it a clear white appearance.

Brown fused alumina contains around 95%-97% alumina (Al2O3). It also has impurities like iron oxide and titanium oxide, giving it a brown color.

| Component | Brown Fused Alumina | White Fused Alumina |

|---|---|---|

| Al₂O₃ | 95–97% | ≥99.5% |

| Fe₂O₃ | ≤0.3% | ≤0.05% |

| TiO₂ | 2–4% | ≤0.03% |

| SiO₂ | ≤1.5% | ≤0.02% |

Physical Characteristics

Both have a hardness of 9 on the Mohs scale, making them ideal abrasives.

White fused alumina is sharper and more brittle, making it perfect for precise polishing and finishing.However, brown fused alumina is tougher and more durable. It handles impacts well, suitable for heavy-duty grinding.

Main Applications

White Fused Alumina Uses

White fused alumina, with its high purity, is ideal for precision polishing in electronics, medical equipment, aerospace parts, advanced refractories, and ceramics.

Brown Fused Alumina Uses

Brown fused alumina is widely used in grinding wheels, sandblasting, abrasive tools, and refractory bricks. Its durability and affordability make it popular for industrial applications.

Cost Differences

White fused alumina is pricier because it uses high-purity materials and specialized production methods. It’s used when purity and precision are essential.

Brown fused alumina is usually less expensive due to lower production costs and widely available raw materials. It is cost-effective for many industries.

Environmental & Safety Aspects

White fused alumina produces less dust and pollution because it has fewer impurities. It’s suitable for clean environments, such as medical and food-related industries.

Brown fused alumina, having more impurities, generates more dust and is generally used in industrial settings with fewer environmental restrictions.

Conclusion

Knowing the differences between white fused alumina and brown fused alumina can help you choose the right material. Consider purity, application requirements, and budget to improve your product performance and cost-efficiency.