Aluminium Hydroxide Uses in Industrial Applications

Date: January-05-2026 Categories: News、Aluminium Hydroxide Views: 55

Aluminium hydroxide uses in industrial applications cover flame retardancy, plastics processing, chemical production, and environmental treatment.

In industrial applications, it plays an important role as a flame retardant filler, processing aid, and raw material for further chemical production.

This article explains the main industrial uses of aluminium hydroxide, focusing on how and why it is applied across different industries.

If you are looking for a simple explanation, you can first read about what aluminium hydroxide is used for before exploring its industrial applications.

Aluminium Hydroxide in Flame Retardant Applications

One of the most important industrial uses of aluminium hydroxide is as a flame retardant filler.

When exposed to high temperatures, aluminium hydroxide releases water vapor and absorbs heat.

This reaction helps lower the material temperature and reduces the spread of fire.

Common applications include:

- Wire and cable compounds

- Plastic housings and enclosures

- Rubber products

- Construction materials

Because it is halogen-free and low in smoke generation, aluminium hydroxide is widely used in safety-focused industries.

Use in Plastics and Rubber Processing

In plastics and rubber manufacturing, aluminium hydroxide functions as both a filler and performance enhancer.

Industrial benefits include:

- Improved fire resistance

- Better thermal stability

- Enhanced surface finish

- Reduced material cost when blended correctly

It is commonly added to PVC, EVA, rubber compounds, and other polymer systems used in industrial products.

Aluminium Hydroxide in Alumina and Chemical Production

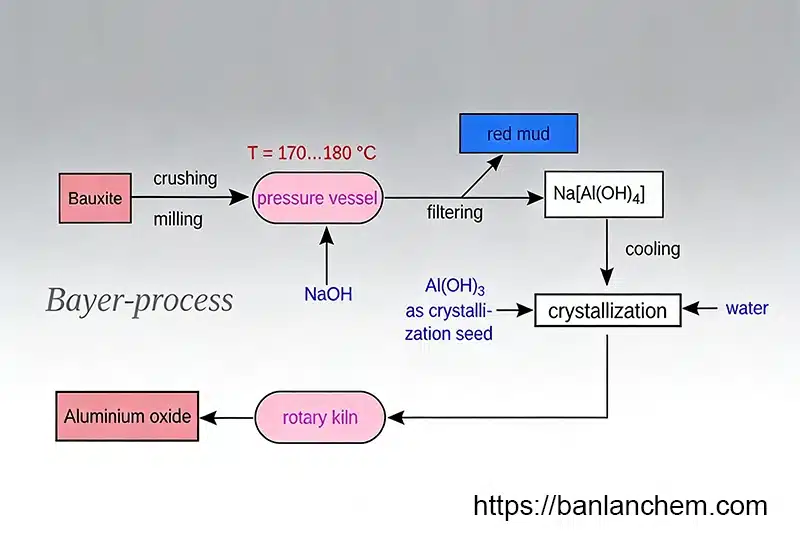

Aluminium hydroxide is a key raw material for producing alumina and other aluminum-based compounds.

In chemical processing:

- It is converted into alumina through controlled calcination

- It serves as an intermediate material in aluminum refining

- It is used in catalyst preparation and specialty chemical production

This makes aluminium hydroxide essential in the broader aluminum and advanced materials industry.

To better understand material differences, you can also read about the difference between aluminium hydroxide and alumina.

Applications in Water Treatment and Environmental Industries

In environmental engineering, aluminium hydroxide is used for water and wastewater treatment.

Its industrial functions include:

- Removing suspended solids

- Helping with flocculation and clarification

- Improving water quality in treatment systems

Because it is effective and relatively easy to handle, it is commonly applied in municipal and industrial water treatment processes.

Use in Paper, Coatings, and Surface Materials

Aluminium hydroxide is also used as a functional filler in paper, coatings, and surface treatment materials.

Benefits in these industries include:

- Improved whiteness and opacity

- Better surface smoothness

- Enhanced coating performance

These properties make it suitable for industrial coatings, specialty papers, and surface-modified materials.

Why Aluminium Hydroxide Is Preferred in Industrial Use

Industries choose aluminium hydroxide because it offers a balance of performance and safety.

Key advantages include:

- Low toxicity and environmental friendliness

- High chemical stability

- Effective heat absorption

- Compatibility with many industrial systems

- Availability in different grades for specific applications

These features allow manufacturers to meet safety standards while maintaining consistent product performance.

Importance of Aluminium Hydroxide in Modern Industry

Aluminium hydroxide plays an important role in modern industrial systems due to its balance of performance, safety, and availability.

It helps manufacturers meet fire safety, environmental, and processing requirements while maintaining stable product quality.

As industries continue to focus on safer and more sustainable materials, aluminium hydroxide remains a reliable choice for industrial applications.

Relationship Between Industrial Use and Material Selection

Different industrial applications require different forms of aluminium hydroxide.

Factors commonly considered include:

- Particle size

- Purity level

- Processing requirements

- Final product performance

Understanding how aluminium hydroxide is used in industrial applications helps manufacturers select the right material for their production needs.

Learn More About Aluminium Hydroxide Applications

To understand the basic concept and general uses, you can read our guide on

what aluminium hydroxide is used for.

For detailed specifications and material information, you can also explore our

aluminium hydroxide powder product page.

Summary

This article focuses on aluminium hydroxide uses in industrial applications and explains how it is applied across different industries.

Aluminium hydroxide is an essential industrial material used across flame retardancy, plastics, chemical processing, water treatment, and surface materials.

Its safety, versatility, and reliable performance make it a preferred choice in many industries.

Understanding the industrial applications of aluminium hydroxide provides valuable insight into why it remains widely used in modern manufacturing.