Aluminum Hydroxide Uses: Applications, Benefits, and Industrial Roles

Date: December-31-2025 Categories: News、Aluminium Hydroxide Views: 78

Aluminum hydroxide uses are closely linked to one simple reason. This material can act as a flame-retardant filler and a functional additive. It is often called ATH (aluminum trihydrate). It is widely used in plastics, rubber, wire and cable, coatings, and many composite systems. This guide explains aluminum hydroxide uses, why it works, and how to choose the right grade for your process.

Table of Contents

- What Is Aluminum Hydroxide (ATH)?

- Why ATH Works in Industry

- Aluminum Hydroxide Uses: Main Applications

- Benefits of Aluminum Hydroxide Uses for Manufacturers

- How to Choose the Right ATH Grade

- How to Use ATH in Formulations (Practical Steps)

- 2–3 Real Practice Results

- Manufacturer, Supplier, Factory, Wholesale Support

- FAQ

What Is Aluminum Hydroxide ATH?

Aluminum hydroxide is an inorganic compound with the formula Al(OH)3. In many technical documents, it is called aluminum trihydrate. In daily factory communication, it is often shortened to ATH. Most grades are white powders with different particle sizes, whiteness levels, and surface treatments.

If you are comparing product options, you can view our product page here: Aluminum Hydroxide Powder.

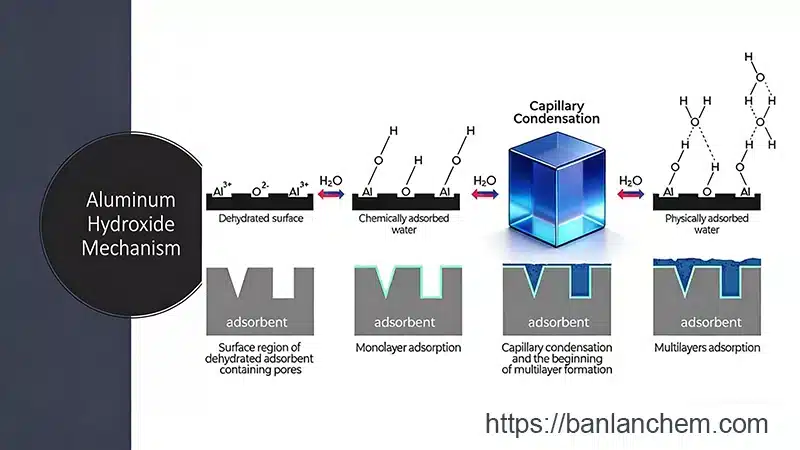

Why ATH Works in Industry

To understand aluminum hydroxide uses, you should know what happens under heat. ATH releases water when heated. This absorbs heat and helps cool the surface. It also dilutes combustible gases. That is why ATH is common in halogen-free flame retardant systems.

- Endothermic cooling: absorbs heat during decomposition

- Water release: reduces the fuel available for burning

- Smoke suppression: can lower smoke density in many systems

- Filler role: can improve stiffness and help cost control

Aluminum Hydroxide Uses: Main Applications

Below are the most common aluminum hydroxide uses in industry. Each application may require a different grade. Focus on particle size, purity, moisture control, and dispersion behavior.

1) Flame Retardant Filler in Plastics

One of the most important aluminum hydroxide uses is as a flame retardant filler in plastics. ATH is used in EVA, PE, PP blends, and other polymer systems. It supports halogen-free flame retardant (HFFR) designs. It can also help improve stiffness and reduce material cost in some formulations.

2) Wire and Cable Compounds (HFFR)

Wire and cable is a major market for ATH. Many compounders use ATH to reduce flame spread and smoke. This is why aluminum hydroxide uses are often discussed in cable material selection.

3) Rubber Products

ATH can be used in rubber sheets, gaskets, seals, and industrial rubber parts. It supports flame retardant performance and can improve filler balance. For rubber systems, dispersion and particle size are usually key.

4) Coatings and Paints

Some coatings use ATH as a functional filler. It can support fire resistance in certain coatings. It can also help adjust surface appearance and mechanical properties based on the grade.

5) Adhesives and Sealants

In epoxy, PU, and silicone systems, ATH can be used as a filler. It may improve dimensional stability and fire behavior. Always confirm compatibility with your resin and curing system.

6) Building Materials and Construction Composites

Construction materials often target flame resistance and low smoke. That makes ATH a useful option for panels, insulation-related products, and composite systems. These are practical aluminum hydroxide uses in the building sector.

7) Smoke Suppressant Packages

ATH is often used with other mineral fillers to reduce smoke. This is common in cable and construction systems. It is another important reason why aluminum hydroxide uses are growing.

8) Ceramic and Glass Processes (As a Precursor)

In some ceramic and glass processes, ATH is used as a precursor. During firing, it can convert into alumina. This may help control chemistry in specific formulations.

9) Alumina (Al2O3) Production Feedstock

ATH is widely used as a feedstock to produce alumina. If you want to compare ATH with alumina powder as an end material, read: Difference Between Alumina Powder and Aluminum Hydroxide.

You can also view our alumina materials here: Alumina Powder.

10) Paper and Specialty Fillers

In some paper and specialty filler markets, ATH supports brightness and functional performance. Requirements vary by process, so focus on particle size distribution and impurity control.

11) Water Treatment and Related Chemical Uses

Aluminum-based materials are used in water treatment and chemical processes. ATH may serve as a raw material for certain aluminum salts and specialty solutions. Always confirm your local compliance requirements and process needs.

12) Polymer Composites and General Fillers

In many polymer composites, ATH supports filler loading targets, stability, and cost balance. If your end product needs higher thermal conductivity, you may also evaluate alumina fillers. But ATH remains a strong choice when flame retardancy is the main goal. These are practical aluminum hydroxide uses for many factories.

Benefits of Aluminum Hydroxide Uses for Manufacturers

Many buyers ask about aluminum hydroxide uses because they want clear benefits. Here are the most common advantages reported in industrial production.

- Improved fire performance: supports halogen-free flame retardant systems

- Lower smoke: helps reduce smoke in many cable and building products

- Stable processing: can work well with the right dispersion method

- Whiteness: supports clean appearance in light-colored products

- Cost control: mineral filler effect helps optimize formulation cost

How to Choose the Right ATH Grade

Choosing the right grade is one of the most important steps for successful aluminum hydroxide uses. A good grade choice can improve performance and reduce complaints. Use this simple checklist.

Step 1: Confirm your target application

- Plastics and polymer compounding

- Wire and cable (HFFR)

- Rubber products

- Coatings, adhesives, and sealants

- Construction composites

Step 2: Choose particle size for your process

- Finer particles can improve surface finish, but may raise viscosity.

- Coarser particles may process easier, but may affect appearance.

- Ask for PSD data if your mixing process is sensitive.

Step 3: Check whiteness and impurity control

- Higher whiteness is important for light-colored plastics, coatings, and cable jackets.

- Impurities can affect color, electrical performance, and long-term stability.

Step 4: Decide if surface treatment is needed

- Treated grades may disperse better in certain polymer systems.

- Untreated grades can work in many standard formulations.

Step 5: Confirm moisture, packaging, and storage

- Moisture control matters for stable compounding and storage.

- Confirm bag type, pallet method, and container loading plans.

Step 6: Request a sample and run a small trial

- Test dispersion, torque, and final mechanical properties.

- Check flame, smoke, and process stability based on your targets.

How to Use ATH in Formulations (Practical Steps)

If you want better results from aluminum hydroxide uses, focus on mixing and dispersion. Small process changes can make a big difference. Below is a practical workflow many factories follow.

Step 1: Pre-dry if needed

- Use controlled drying if your plant environment is humid.

- Keep ATH bags sealed before use.

Step 2: Add ATH in a stable feeding order

- Add ATH slowly to avoid powder agglomeration.

- Use a consistent mixing speed and feeding time.

Step 3: Improve dispersion

- Use suitable dispersants if your system needs it.

- Check whether surface-treated ATH improves your mixing stability.

Step 4: Validate key targets

- Check color and surface finish.

- Check smoke and fire behavior based on your standards.

- Check mechanical properties for real production conditions.

2–3 Real Practice Results

Every formulation is different. But many manufacturers report similar outcomes when they match the right ATH grade and run stable mixing steps. Here are common results related to aluminum hydroxide uses.

- Result 1: improved flame retardant performance in halogen-free cable compounds

- Result 2: lower smoke and cleaner burning behavior in construction composites

- Result 3: better surface appearance in light-colored plastics and coatings

Manufacturer, Supplier, Factory, Wholesale Support

Banlan is an aluminum hydroxide Manufacturer and Supplier serving industrial customers. Our Factory supports consistent quality control, stable logistics, and export-ready documents. We also provide Wholesale supply for flame retardant filler and industrial additive applications. Learn more at https://banlanchem.com.

FAQ

What are the most common aluminum hydroxide uses?

The most common aluminum hydroxide uses are flame retardant filler roles in plastics, wire and cable compounds, and construction-related composites, plus general filler uses and alumina feedstock roles.

Is ATH better than magnesium hydroxide for flame retardant uses?

It depends on your system and processing temperature. ATH releases water at a lower temperature range than magnesium hydroxide, so ATH is often used in many polymer systems where that behavior fits the design. For selection, focus on your resin type, processing temperature, and target standards.

How can I choose a reliable ATH supplier?

Start with stable quality, clear particle size data, and consistent whiteness. Then confirm packaging, moisture control, and technical support. You can also read: How to Choose a Reliable Aluminum Hydroxide Powder Supplier.

If you want a strong and stable page for aluminum hydroxide uses, keep the structure clear. Use short paragraphs, practical steps, and a focused internal linking plan. This approach supports ranking and long-term traffic growth.