YS/T 89-2023 Industry Standard for Calcined α-Alumina: Key Changes and Practical Insights

Why This Standard Was Revised

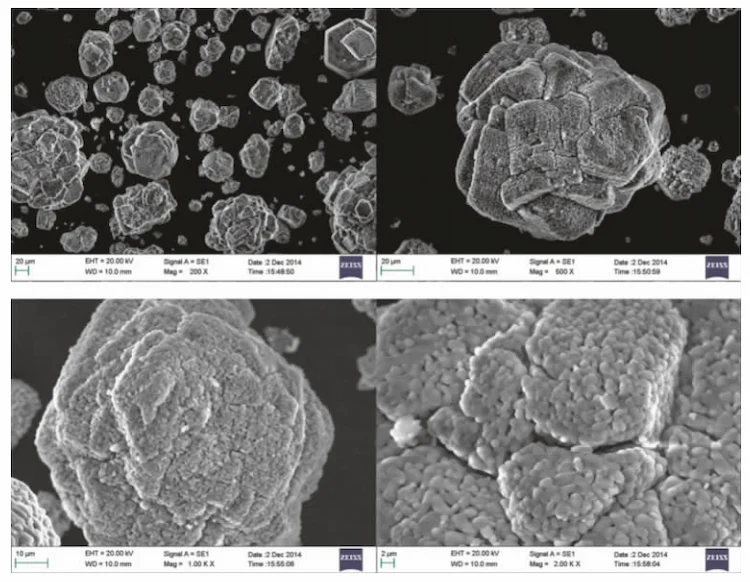

Calcined α-alumina—also known as high-temperature Calcined alumina—is a dense and thermally stable form of alumina. It’s created by heating aluminum hydroxide or metallurgical alumina at 1250°C to 1600°C, resulting in a material with over 90% α-phase content. This gives it a high melting point (2053°C) and exceptional hardness (Mohs 9), second only to diamond.

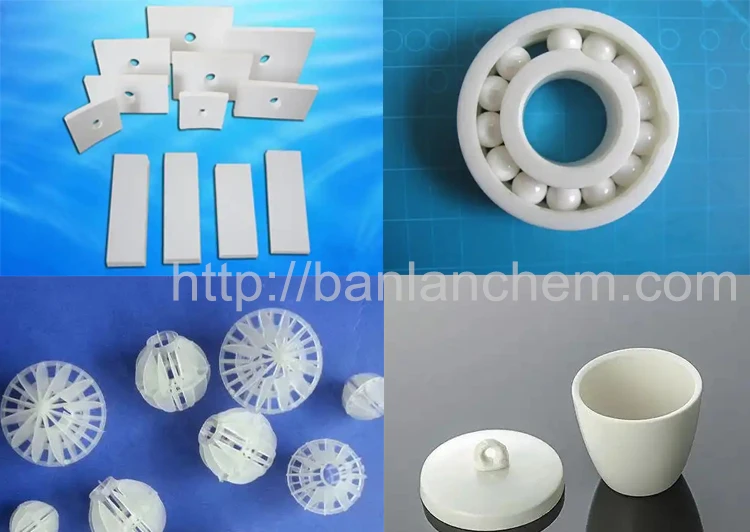

Its purity and stability make it essential in ceramics, refractories, precision polishing, and glass. However, the earlier standard YS/T 89-2011 couldn't keep pace with market needs. It lacked sufficient product classifications, did not define crystal size requirements, and relied on outdated testing methods.

The updated YS/T 89-2023, implemented on July 1, 2024, reflects current technical standards and industry demands. It supports the development of next-generation materials for both domestic and global markets.

What’s New in YS/T 89-2023

1. Expanded Use Cases

The new version expands the standard’s scope to include applications in daily-use ceramics and specialty glass, alongside traditional roles in refractories and alumina-based ceramics.

2. Updated Product Classifications

- Product naming now aligns with YS/T 619-2021: "A-C" for raw powders, "A-CG" for micropowders.

- 14 new grades were introduced, such as A-C-03, A-C-10R, and A-CG-5ALS, to meet specialized demands.

- Two outdated grades (A-C-05LS and A-C-10LS) were removed to reduce confusion.

- Numbers in raw grades indicate sodium oxide content; in micropowders, they refer to median particle size (D50).

3. Technical Adjustments and Testing Enhancements

- New classification of raw powders based on α-Al₂O₃ content, impurity levels, and D50 values after 24-minute grinding.

- All grades must meet specific D50 targets, now used as part of product grading.

- The method for calculating Al₂O₃ has been clarified: it subtracts all measured impurities, including trace elements ≥0.010%.

- Clients can request custom parameters like shrinkage rate, grain size, or trace element limits by agreement.

4. Safer Particle Size Testing

The previous +45μm test method used acetone, which posed health and safety risks. It has been replaced with a safer method based on GB/T 6609.27.

5. Smarter Sampling for Different Package Sizes

As product packaging now ranges from 25kg to 1400kg, the updated standard includes more flexible sampling rules. This ensures quality control regardless of package weight.

How Calcined α-Alumina Is Used Worldwide

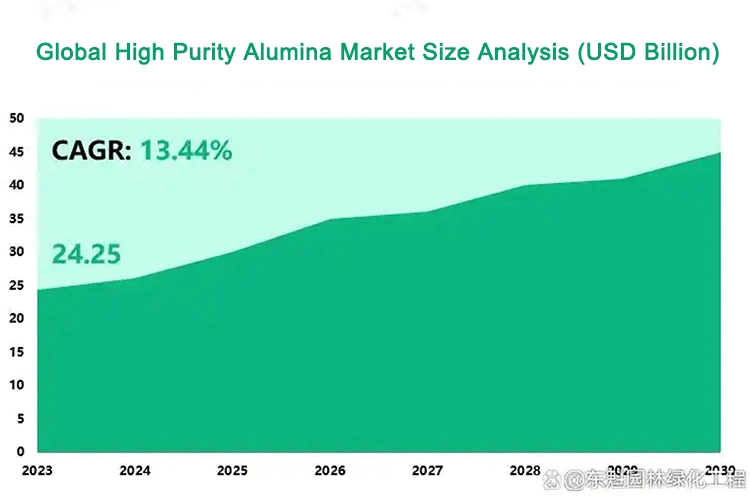

Globally, α-alumina plays a role in high-end applications. In Japan, it’s critical for advanced ceramics. German manufacturers use it in optical glass. U.S. companies apply it in electronics and refractories. With industries focusing more on clean energy and lightweight materials, demand continues to grow.

How It Compares to Other Alumina Types

Compared to γ-alumina, which has high surface area and is widely used in catalysts, α-alumina is more stable and ideal for structural applications. Unlike tabular alumina—which is sintered without binders—calcined α-alumina offers finer control over purity and particle size.

Compliance & Export Notes

YS/T 89-2023 is more aligned with international testing and packaging standards, which simplifies export procedures. Removing acetone-based tests also makes the process safer and more sustainable—important for customers prioritizing environmental compliance.

Frequently Asked Questions (FAQ)

- What industries use calcined α-alumina? Ceramics, refractories, glass, polishing, and electronics.

- What is the typical Al2O3 purity? Most grades exceed 99%, with tightly controlled impurity levels.

- Can the specifications be customized? Yes. Tailored solutions for D50, impurity levels, and more are common in B2B supply contracts.

- Is this product ready for export? Absolutely. The standard updates improve cross-border usability and product transparency.

Why This Revision Matters

The 2023 revision of YS/T 89 is a practical response to evolving industry needs. It reflects better technology, safer testing, and more relevant classifications. For manufacturers aiming at global markets, this standard provides both a roadmap and a benchmark.

Closing Thoughts

YS/T 89-2023 isn’t just a rulebook—it’s a tool for progress. Whether you’re sourcing materials, improving processes, or developing new ceramics or abrasives, the updated standard gives you a reliable framework to move forward confidently in a competitive market.