How Tabular Alumina Enhances Polymer Composites: Structure, Benefits, and Preparation Methods

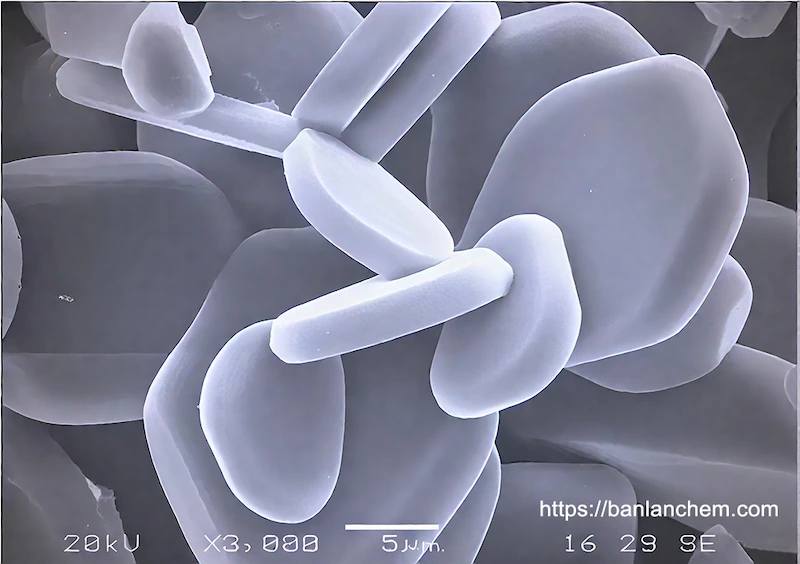

To enhance the performance of polymer composites, fillers are often added. The shape of the filler—particles, fibers, spheres, or plates—greatly affects final properties. Among them, Tabular Alumina stands out for its structure and performance advantages.

Why Use Tabular Alumina?

Tabular Alumina offers high melting point, hardness, mechanical strength, chemical resistance, oxidation resistance, and thermal stability. Its flat, plate-like grains with high aspect ratios help improve stiffness and bending strength in composite products.

Learn more:Tabular Alumina Supplier – Uses and Properties Explained

Additionally, Tabular Alumina has good surface reactivity, making it easy to modify and bond with polymer matrices. It disperses well without heavy agglomeration, ensuring consistent performance in composite applications.

Main Preparation Methods of Tabular Alumina

1. Molten Salt Method

This method uses low-melting-point salts as a medium to grow tabular alumina grains at high temperatures. Additives like phosphorus or titanium help control the size and shape of the crystals.

2. Sol-Gel Method

Sol-gel processing forms a gel from a solution through hydrolysis and condensation. This approach enables molecular-level mixing and results in well-distributed tabular alumina after drying and calcination.

3. Hydrothermal Method

In this method, reactions occur in sealed vessels with high temperature and pressure. It produces high-purity, well-formed alumina grains with minimal agglomeration—ideal for advanced composites.

4. High-Temperature Sintering

Tabular Alumina is typically produced by sintering α-alumina at around 1900°C. Additives can help lower the required sintering temperature and control the anisotropic crystal growth.

5. Mechanical Processing

Using mills like ball mills or jet mills, powders are ground and shaped into fine tabular structures through mechanical force. This method is simple but energy-intensive.

6. Film-Coating Method

Sol-gel is coated on a smooth surface, dried, and peeled to obtain thin, smooth alumina flakes. Though clean and well-shaped, the particles may require further classification for size control.

Benefits of Tabular Alumina in Polymer Composites

1. Mechanical Strength

Tabular Alumina has a large surface area and high aspect ratio, which allows strong bonding with the polymer. Surface-modified alumina can greatly enhance mechanical properties of composites.

Its reinforcement effect depends on proper dispersion and good interface bonding. Choosing the right mixing and surface treatment process is key to performance.

2. Thermal Conductivity

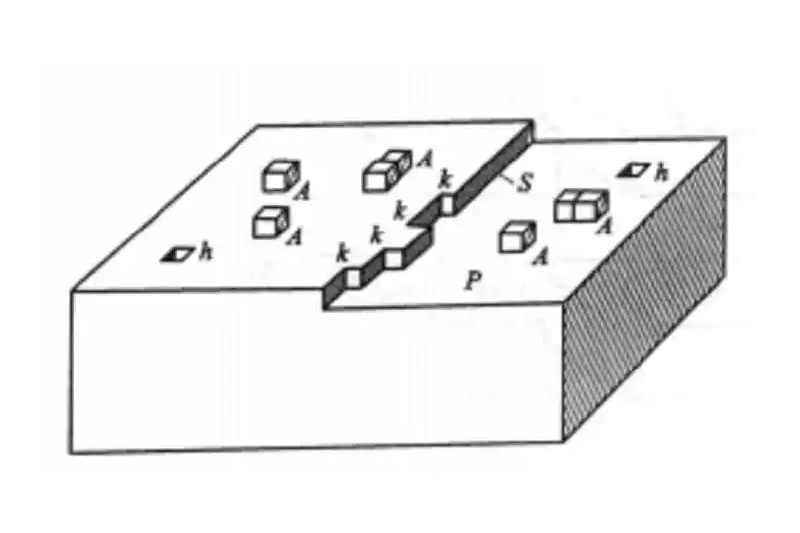

Tabular Alumina has high thermal conductivity (up to 38 W/m·K), compared to less than 0.3 W/m·K for many polymers. When enough filler is added, continuous thermal pathways form inside the polymer matrix.

Though spherical and irregular alumina are widely used, tabular structures—similar to graphite or boron nitride—are also effective at forming these heat transfer paths.

This makes Tabular Alumina suitable for thermal interface materials, electronics, automotive components, and other high-performance applications.

BANLANCHEM Aluminum Oxide-Based Chemicals: Activated alumina, high temperature calcined alumina,Tabular Alumina, high-purity alumina, pseudo-boehmite, boehmite, catalyst carriers, fused alumina, and alumina products for industries like refractories, ceramics, abrasives, and electronics.