Alumina Powder Uses Across Ceramics, Polishing, Refractories, and Electronics

Alumina powder is widely used in industrial applications that require high hardness, thermal stability, and chemical resistance. It plays a critical role in ceramics manufacturing, surface polishing, refractory materials, and electronic components. Because different industries demand different purity levels and particle sizes, understanding the real uses of alumina powder is essential before material selection or bulk purchasing.

In industrial supply chains, alumina powder is not a single standardized material. Its performance varies significantly depending on calcination temperature, crystal phase, and particle-size distribution. For manufacturers, engineers, and procurement teams, knowing which type of alumina powder is used for which application helps reduce production risk, control costs, and ensure stable long-term supply from a reliable manufacturer or supplier.

Alumina powder uses are wide and practical. Many industries rely on alumina powder every day. It is used for ceramics, refractories, polishing, electronics, and catalyst support. If you are buying for a factory line, you need clear answers. This guide explains alumina powder uses in simple words. It also helps you choose the right grade and the right supplier.

Alumina powder is used across multiple industries due to its hardness, thermal stability, and chemical resistance.

- Table of Contents

- What Is Alumina Powder?

- Why Alumina Powder Is Used So Often

- Main Applications of Alumina Powder

- Alumina Powder Uses in Ceramics, it improves strength and wear resistance

- Alumina Powder Uses in Refractory Material , it enhances high-temperature stability

- Alumina Powder Uses for Polishing and Abrasives, it delivers controlled surface finishing

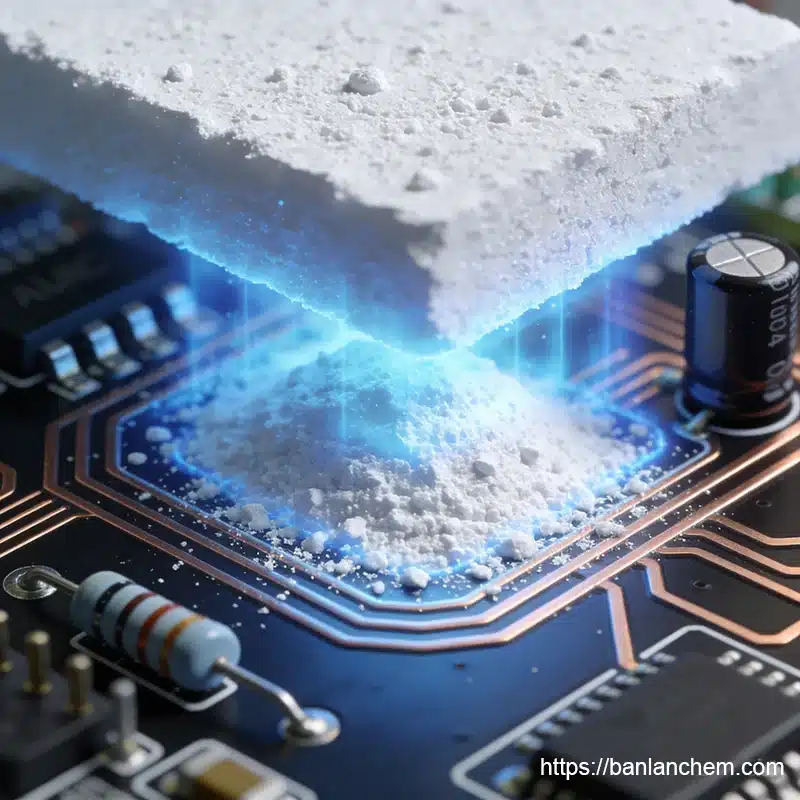

- Alumina Powder Uses in Electronics it provides electrical insulation and heat dissipation

- Applications of Alumina Powder as Catalyst Support

- How to Choose the Right Alumina Powder

- Quality Checks Before You Buy

- Packing, Storage, and Shipping Tips

- Manufacturer, Supplier, Factory, Wholesale

- FAQ

Different applications require different alumina powder grades, purity levels, and particle sizes

Table of Contents

Use the links above to jump to the part you need. Each section explains real alumina powder uses.

What Is Alumina Powder?

Alumina powder is aluminum oxide in powder form. It is often written as Al2O3. It can be made in different grades and sizes. Some grades are very pure. Some grades are designed for tough industrial work. Because it is stable and hard, it fits many applications. That is why alumina powder uses keep growing.

In simple terms, alumina powder is used when you need:

- High heat resistance

- Strong wear resistance

- Good chemical resistance

- Stable performance in production

Why Alumina Powder Is Used So Often

There are many reasons for popular alumina powder uses. It works well in hot, hard, and demanding environments. It can also be processed in many ways. It can be pressed, sintered, mixed, or coated. This gives engineers more choices.

Key benefits that support many alumina powder uses:

- Hardness: It helps protect surfaces and parts.

- Heat stability: It stays stable at high temperature.

- Electrical insulation: It is useful in electronics.

- Chemical stability: It resists many acids and bases.

- Flexible grades: Different purity and particle sizes are available.

If you want specs and supply details, start here: Alumina Powder Product Page.

Main Alumina Powder Uses

Let’s get into the most common alumina powder uses. These uses cover the industries that most buyers ask about. If you are a purchasing manager, focus on the fit. If you are an engineer, focus on the grade and particle size.

Alumina powder is widely used in polishing, ceramics and refractory applications due to its hardness and chemical stability.

For industrial processes that require higher thermal stability and consistent performance,

calcined alumina is commonly applied as a processed alumina material.

Here is a quick map of common alumina powder uses:

- Ceramics and advanced ceramics

- Refractory bricks, castables, and furnace linings

- Polishing powders and abrasive systems

- Electronics substrates and insulation parts

- Catalyst support and chemical processing

Applications of Alumina Powder in Ceramics

One of the largest alumina powder uses is ceramics. Ceramic makers use alumina powder to build strong and stable parts. These parts can handle heat, wear, and pressure. They can also keep size and shape well after sintering.

Common ceramic alumina powder uses include:

- Wear-resistant ceramic parts

- Ceramic tubes and rods

- Industrial seals and valves

- Ceramic liners and sleeves

- High-purity ceramic components

What matters most for ceramic alumina powder uses:

- Purity (higher purity can improve performance)

- Particle size (affects sintering and density)

- Consistency (stable batches help stable production)

Tip: If your ceramic line has cracking or low density, check powder size distribution. A stable distribution often improves results.

Alumina powder is widely used in ceramic materials because of its high hardness and heat resistance. One of the most important applications is alumina powder uses in ceramics , where it helps improve strength, wear resistance, and thermal stability.

For industrial polishing and advanced ceramics, calcined alumina powder is one of the most commonly used forms due to its stable crystal structure and controlled particle size. Many manufacturers and suppliers prefer calcined alumina for applications that require consistent performance and reliable bulk supply.

How Bonding Affects Alumina Properties

Understanding alumina bonding helps explain why alumina’s physical properties make it useful in the applications discussed above. In aluminum oxide (Al₂O₃), the strong ionic bonding between aluminum ions (Al³⁺) and oxygen ions (O²⁻) gives alumina its high melting point, excellent hardness, and thermal stability, which in turn supports its use in refractories, ceramics, abrasives, and electrical insulation.

For a broader and more detailed explanation of how bonding shapes alumina’s structure and properties, see our in-depth article on alumina bonding.

Alumina Powder Uses in Refractory Materials

Another major group of alumina powder uses is refractory production. Refractory materials protect furnaces and kilns. They face high heat, thermal shock, and chemical attack. Alumina helps improve strength and heat stability.

Typical refractory alumina powder uses:

- High-alumina refractory bricks

- Castables and monolithic refractories

- Furnace and ladle linings

- Kiln furniture

- Heat-resistant coatings

What buyers often check for refractory alumina powder uses:

- Al2O3 content

- Impurity level (some impurities affect refractoriness)

- Packing and flow behavior (for mixing and casting)

If you also work with hydroxide fillers, this related guide may help: What Is the Difference Between Alumina Powder and Aluminum Hydroxide?

Alumina Powder Uses for Polishing and Abrasives

Polishing is a well-known area of alumina powder uses. Alumina is hard. It can remove tiny surface layers. It can also help create a smooth finish. That is why it is used on metals, glass, ceramics, and more.

Common polishing and abrasive alumina powder uses:

- Metal polishing for stainless steel and alloys

- Glass polishing and finishing

- Ceramic polishing

- Precision surface finishing

- Abrasive slurries and compounds

What matters most for polishing alumina powder uses:

- Particle size (fine powder for smooth finish)

- Particle shape (affects cut rate)

- Cleanliness (low contamination supports better results)

If your finish is not stable, you may need a tighter size range. A small change can make a big difference.

Alumina Powder Uses in Electronics

Electronics is another important area of alumina powder uses. Alumina ceramics can insulate electricity. They can also move heat away from components. That helps devices run safer and last longer.

Typical electronics Applications of Alumina Powder:

- Ceramic substrates

- Electrical insulation parts

- Heat dissipation components

- Electronic packaging materials

- High-temperature insulation

For electronics Applications of Alumina Powder, buyers often prefer:

- Higher purity

- Stable dielectric performance

- Good sintering behavior

If you need guidance on selecting a reliable supplier, this page can help: How to Choose a Reliable Supplier

Applications of Alumina Powder as Catalyst Support

Catalyst support is a special group of Applications of Alumina Powder. In chemical processing, catalysts need a stable support structure. Alumina can provide surface area and strength. It can also resist chemicals and temperature changes.

Common catalyst support alumina powder uses:

- Petrochemical catalyst supports

- Environmental catalyst supports

- Chemical reaction supports

- Carrier materials for active components

For catalyst-related Applications of Alumina Powder, powder features may include:

- Specific surface area needs

- Pore structure needs

- Stable phase and composition

How to Choose the Right Alumina Powder

Different Applications of Alumina Powder require different grades. So you should not buy based on price only. You should match the powder to the process. This reduces problems later. It also saves total cost.

Here is a simple step-by-step selection guide:

- Step 1: Confirm your application (ceramics, refractory, polishing, electronics, catalyst).

- Step 2: Choose purity level (standard, high purity, ultra-high purity if needed).

- Step 3: Choose particle size range (fine, medium, or custom range).

- Step 4: Check batch consistency and testing reports.

- Step 5: Ask about packing, MOQ, and lead time.

Quality Checks Before You Buy

Good results depend on good checks. This is true for all alumina powder uses. Even small differences can change performance. So you should ask for clear quality documents.

Basic checks many buyers request:

- Purity (Al2O3 content)

- Impurity limits (such as Na, Fe, Si)

- Particle size distribution (PSD)

- Moisture level

- Bulk density and tap density (if needed)

Practical buying tips for stable alumina powder uses:

- Ask for a recent COA for the same grade.

- Request a sample if your process is sensitive.

- Confirm packaging and storage recommendations.

- Check whether the supplier can keep batch-to-batch stability.

Packing, Storage, and Shipping Tips

Packing and storage matter. Powder quality can change with moisture. This affects many alumina powder uses, especially fine powder. So you should store it in a dry place. You should also keep bags sealed.

Common packing options:

- 25 kg bags

- Jumbo bags for bulk shipping

- Palletized export packing

Storage tips:

- Keep in a dry warehouse.

- Avoid direct ground contact.

- Use first-in, first-out (FIFO).

- Seal opened bags well.

Alumina Powder Manufacturer, Supplier, Factory, Wholesale

If you buy for long-term production, the supply chain matters. Working with a stable Manufacturer helps control quality. A professional Supplier can support faster response and better service. A real Factory can offer stable production and batch control. For large orders, Wholesale supply helps reduce total cost.

At BanlanChem, we focus on stable quality and practical support. We serve global buyers who need consistent performance for different Applications of Alumina Powder.

What you can request from a serious Manufacturer and Supplier:

- Clear grade options for different alumina powder uses

- Stable batch supply for long-term projects

- COA and basic technical documents

- Export packing and shipping support

- Wholesale pricing for bulk orders

FAQ

What are the most common alumina powder uses?

The most common Applications of Alumina Powder include ceramics, refractories, polishing, electronics insulation, and catalyst support.

How do I choose alumina powder for ceramics?

For ceramic alumina powder uses, check purity, particle size distribution, and batch consistency. These factors affect sintering and final density.

Is Applications of Alumina Powder for high-temperature furnace linings?

Yes. Many refractory alumina powder uses are for furnace linings, bricks, and castables. Alumina helps improve heat resistance and strength.

Does particle size matter for alumina powder uses?

Yes. Particle size is important for many alumina powder uses. Fine sizes can help polishing and sintering. Coarser sizes can help packing and flow in some mixes.

Where can I find alumina powder specifications and supply?

You can visit our Alumina Powder page for product details, grades, and supply information.