What Is Aluminium Hydroxide Used For? 12 Industrial Uses, Benefits & How to Choose the Right Grade

Date: August-28-2025 Categories: News、Aluminium Hydroxide Views: 195

What is aluminium hydroxide used for in real factories and real products? Aluminium hydroxide (also called aluminum hydroxide, ATH) is a white inorganic powder. It is used as a flame retardant filler, a smoke suppressant, and a functional additive in many industries. This guide explains the most common uses, why it works, and how to choose the right grade for your application.

Table of Contents

- What Is Aluminium Hydroxide Used For?

- What Is Aluminium Hydroxide (ATH)?

- Why Aluminium Hydroxide Works

- 12 Major Uses of Aluminium Hydroxide

- 2 Common Questions (With Clear Answers)

- Benefits for Manufacturers

- How to Choose the Right Aluminium Hydroxide Grade (Step by Step)

- Real Practice Results (What Buyers Often See)

- FAQ

What Is Aluminium Hydroxide Used For?

What is aluminium hydroxide used for most often? It is widely used as:

- a flame retardant filler in plastics, rubber, and cable compounds

- a smoke suppressant in wire & cable and construction materials

- a functional additive in coatings, adhesives, and composites

- a feedstock for alumina (Al2O3) production

- a raw material in water treatment and some chemical processes

What Is Aluminium Hydroxide (ATH)?

Aluminium hydroxide is an inorganic compound with the formula Al(OH)3. It is usually a white powder. In industry, it is often called ATH (aluminum trihydrate). Many buyers also search using British spelling, so you will see both: aluminium hydroxide and aluminum hydroxide.

If you sell or buy ATH as a product, you can link to your product page like this: Aluminum Hydroxide Powder (ATH) Product Page.

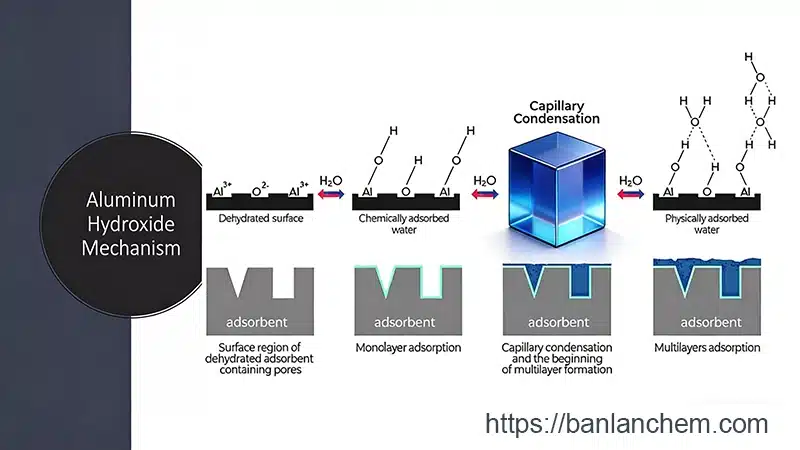

Why Aluminium Hydroxide Works

To understand what is aluminium hydroxide used for, you need to know what it does under heat. ATH releases water when heated. This helps cool the material surface. It also dilutes flammable gases. That is why ATH is a common flame retardant filler.

- Endothermic cooling: absorbs heat during decomposition

- Water release: lowers surface temperature and reduces fuel gases

- Smoke suppression: can reduce smoke density in many formulations

- Filler function: improves stiffness, dimensional stability, and cost control

12 Major Uses of Aluminium Hydroxide

Below are the most common answers to what is aluminium hydroxide used for. Different industries need different particle size, whiteness, and surface treatment. So always match the grade to the end use.

1) Flame Retardant Filler in Plastics

ATH is used in PE, EVA, PP, PVC blends, and many engineered plastics. It helps improve fire performance in halogen-free systems. It also acts as a mineral filler for cost and stiffness control.

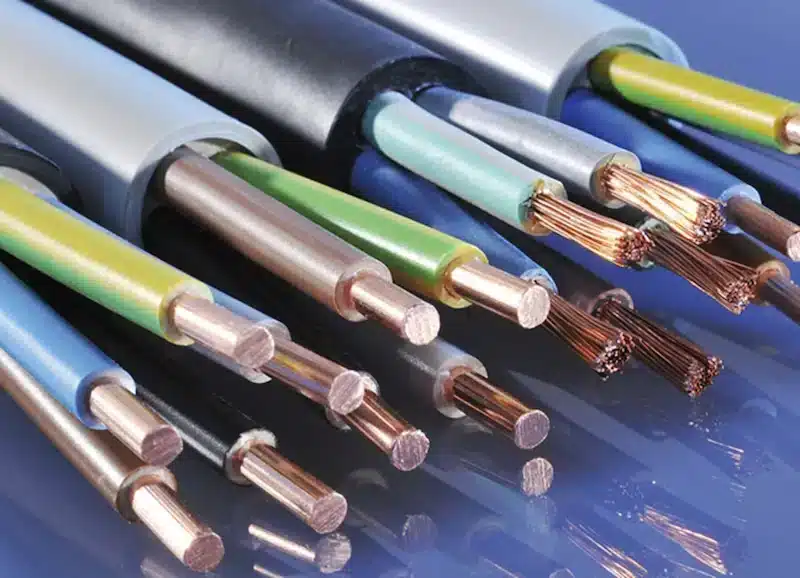

2) Wire & Cable Compounds (HFFR)

One of the biggest uses is halogen-free flame retardant cable compounds. ATH supports lower smoke and safer fire behavior. This is a key reason what is aluminium hydroxide used for is searched by cable factories.

3) Rubber Products

ATH can be used in rubber sheets, seals, belts, and other rubber parts. It can help with flame retardancy and reduce smoke. It also improves filler balance in certain recipes.

4) Building Materials

ATH is used in panels, insulation systems, sealants, and some construction composites. It supports flame retardancy and smoke suppression. It can also improve surface appearance when whiteness is important.

5) Coatings and Paints

ATH can be used as a functional filler in coatings. It helps improve fire resistance in some systems. It can also help with matting and mechanical reinforcement, depending on grade.

6) Adhesives and Sealants

In epoxy, PU, silicone, and other systems, ATH can act as a filler. Some formulations use it to improve fire behavior and thermal stability.

7) Polymer Composites and Thermal Management

In certain composite systems, ATH helps control cost and improve stability. For thermal management, alumina fillers are often used. But ATH can be used where processing and cost targets fit. If your end product needs higher thermal conductivity, you may also compare with alumina fillers: Alumina Powder.

8) Ceramics and Glass (Specific Additive Uses)

ATH can be used as a raw material in some ceramic or glass processes. It can convert into alumina during firing. This can help control chemistry and sintering behavior.

9) Alumina Production Feedstock

ATH is a common intermediate for producing alumina (Al2O3). Many buyers ask what is aluminium hydroxide used for because they also need alumina products. To understand the difference, see: Difference Between Alumina Powder and Aluminum Hydroxide.

10) Water Treatment and Chemical Processes

Aluminum-based compounds are used in water treatment and related processes. ATH may be used as a raw material for certain aluminum salts or specialty chemicals. Always confirm your process needs and local regulations.

11) Paper and Specialty Fillers

In some paper and specialty filler uses, aluminum hydroxide can support brightness and functional performance. Requirements vary widely by process. Focus on particle size distribution and impurity control.

12) Smoke Suppressant Packages

In some formulations, ATH is used together with other fillers to reduce smoke. This is common in cable and construction systems. It is another key answer to what is aluminium hydroxide used for.

2 Common Questions (With Clear Answers)

Question 1: Is aluminium hydroxide the same as ATH (aluminum trihydrate)?

In most industrial contexts, yes. ATH is a common industry name for Al(OH)3. However, grades can differ by purity, particle size, surface treatment, and moisture. So the name may be the same, but performance can differ.

Question 2: Why do some formulas use alumina instead of aluminium hydroxide?

Alumina (Al2O3) and aluminium hydroxide (Al(OH)3) are different materials. Alumina usually has higher hardness and higher-temperature stability as a ceramic material. ATH releases water under heat, so it is stronger for flame retardant filler roles in many polymer systems. If you are unsure which fits your use, compare them here: Alumina vs Aluminum Hydroxide.

Benefits for Manufacturers

When people ask what is aluminium hydroxide used for, they often want practical benefits. Here are the main advantages buyers look for:

- Better fire performance: supports halogen-free flame retardant systems

- Lower smoke: helps smoke suppression in many cable and building products

- Stable processing: many ATH grades disperse well with the right mixing process

- Cost control: mineral filler effect can help optimize formulation cost

- Whiteness: supports clean appearance in light-colored products

How to Choose the Right Aluminium Hydroxide Grade (Step by Step)

If you want better performance and fewer complaints, use this simple selection process. This section is also critical for ranking, because it answers “how to” intent.

Step 1: Confirm your target use case

- Wire & cable (HFFR)

- Plastics (EVA/PE/PP/PVC blends)

- Rubber

- Coatings / adhesives

- Building materials

Step 2: Choose the right particle size

- Finer particles can improve surface finish, but may increase viscosity.

- Coarser particles may process easier, but can affect appearance.

- Ask for PSD data if your process is sensitive.

Step 3: Check purity and impurities

- Higher purity helps stable performance in demanding products.

- Impurities can affect color, electrical properties, and long-term stability.

Step 4: Decide if you need surface treatment

- Some polymer systems benefit from treated ATH for better dispersion.

- Untreated ATH may work well in simpler formulas.

Step 5: Match moisture and packaging to your process

- Moisture control matters for storage and mixing stability.

- Confirm bag type, pallet method, and container loading plan.

Step 6: Request a sample and do a small trial

- Test dispersion, torque, and final product properties.

- Check smoke, flame, and mechanical targets as needed.

If you need a quick technical overview of ATH itself, you can also link to: What Is Aluminum Hydroxide Powder?.

Real Practice Results (What Buyers Often See)

Results depend on your resin system, loading level, and processing. But many users report these outcomes after choosing the right ATH grade and dispersion method:

- Result 1: improved flame retardant performance in halogen-free cable compounds

- Result 2: lower smoke and cleaner burning behavior in construction-related products

- Result 3: smoother surfaces and more stable color in light-colored plastics or coatings

FAQ

What is aluminium hydroxide used for in plastics?

It is used as a flame retardant filler and smoke suppressant in many polymer systems. It can also help adjust stiffness and processing cost, depending on the formula.

What is aluminium hydroxide used for in cable compounds?

It is widely used in halogen-free flame-retardant (HFFR) cable compounds. It helps improve fire safety and reduce smoke in many applications.

Does aluminium hydroxide always replace halogen flame retardants?

Not always. System design depends on performance targets, regulations, and processing limits. Many halogen-free systems use ATH as a main filler, sometimes with other additives.

Summary: If you are targeting the keyword what is aluminium hydroxide used for, keep the page focused on uses, benefits, and selection steps. Then support it with internal links to your product page and related guides.