Calcined Alumina (α-Al2O3) is a high-purity aluminum oxide powder produced under controlled calcination conditions. It is widely used in precision polishing, advanced ceramics, refractories, and electronic materials where stable performance, controlled particle size, and chemical purity are required.

BanlanChem is a professional Calcined Alumina Manufacturer, Supplier, and Factory, providing consistent quality, tight particle-size control, and reliable Wholesale supply for global industrial buyers.

Contents

- Product Overview

- Key Features & Advantages

- Applications of Calcined Alumina

- Grades & Particle Size Options

- Typical Technical Specifications

- Processing & Surface Options

- Packaging & Logistics

- Quality Control & Traceability

- How to Choose Calcined Alumina

- FAQ

- Related Products & Comparisons

- Contact the Manufacturer

Product Overview

Calcined Alumina is produced by calcining aluminum hydroxide or precursor alumina at carefully controlled temperatures to transform it into a stable alpha phase (α-Al2O3). Compared with hydrated alumina, calcined alumina offers higher hardness, lower loss on ignition, better thermal stability, and predictable sintering behavior.

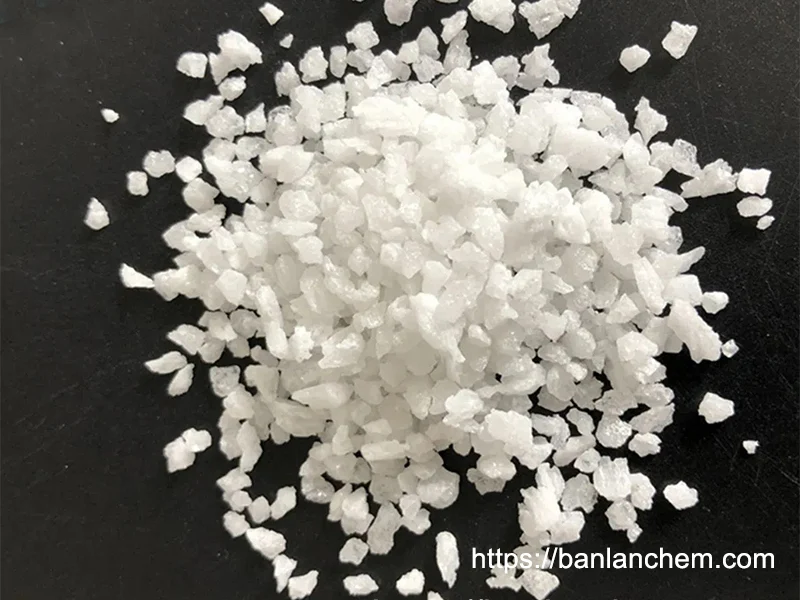

Our calcined alumina powder features high whiteness, consistent hardness, good flowability, and excellent dispersion performance. It is suitable for dry processing, slurry systems, and various ceramic forming methods such as pressing, tape casting, and slip casting.

If you want to review all alumina grades before choosing, you can see our full range here: Alumina Powder Product Series.

Key Features & Advantages

- High purity: Low Na2O and low Fe2O3 for clean firing and bright surfaces.

- Stable α-phase: Predictable sintering and excellent high-temperature stability.

- Controlled PSD: Narrow particle size distribution for smooth polishing and dense ceramics.

- Good flow & dispersion: Improves mixing, packing, and process consistency.

- High hardness: Suitable for abrasive, lapping, and surface finishing applications.

- Manufacturer direct supply: Stable quality with flexible wholesale options.

The excellent thermal stability and mechanical strength of calcined alumina are closely related to its crystal structure. Strong ionic bonding between aluminum and oxygen ions forms a dense lattice, which enhances rigidity and high-temperature resistance in demanding industrial environments.

Applications of Calcined Alumina Powder

1. Ceramics & Advanced Ceramics

Calcined alumina is a fundamental raw material for alumina ceramics, including spark plugs, wear-resistant parts, electronic substrates, and structural ceramics. Fine particle size and controlled impurities help achieve high density and strength.

2. Refractories

Used in high-temperature castables, refractory bricks, and furnace linings. Calcined alumina provides thermal stability, corrosion resistance, and reliable performance in harsh operating conditions.

3. Polishing & Abrasives

With a Mohs hardness close to 9, calcined alumina is widely used for polishing metals, ceramics, optical components, and semiconductor materials. Controlled particle size distribution helps reduce scratches and improve surface finish.

For polishing-focused users, see our detailed guide here: Calcined Alumina Polishing.

4. Catalyst Carriers & Electronics

High-purity calcined alumina can be used as catalyst supports and in electronic materials where chemical stability and purity are critical.

For high-density or thermal-shock-resistant aggregates, you may also compare with: Tabular Alumina.

Grades & Particle Size Options

We supply multiple Calcined Alumina grades. Selection is based on particle size, purity level, and application requirements. Custom particle size cuts are available from our factory.

- Microfine: D50 ≈ 0.4–1.0 μm, for precision polishing and fine ceramics.

- Fine: D50 ≈ 1–3 μm, for ceramic forming and dense bodies.

- Medium: D50 ≈ 3–6 μm, for refractories and general ceramics.

- Coarse: D50 > 6 μm, for special blends and castables.

Typical Technical Specifications

The following specifications are typical reference values. Exact data depend on grade and application. Please contact our manufacturer team for batch COA and grade confirmation.

Ordinary Calcined Alumina

High quality aluminum hydroxide as raw material, it is calcined by rotary kiln at reasonable calcine temperature. It has the advantages of high conversion rate, crystal stability, high mechanical strength, stable shrinkage rate, wear resistance, corrosion resistance and high temperature resistance.

| Brand | Chemical composition(%) | α-Al2O3 | Effective density | Primary crystal size | ||||

| Al2O3≥ | SiO2≤ | Fe2O3≤ | Na2O≤ | L.O.I≤ | %≥ | ≥ | μm | |

| AC-30 | 99.0 | 0.10 | 0.04 | 0.5 | 0.20 | 94 | 3.93 | 4±1 |

| AC-30-A | 99.0 | 0.10 | 0.04 | 0.5 | 0.20 | 93 | 3.93 | 2.5±1 |

Application: various abrasives, abrasives and various wear-resisting filler, various ceramic and refractory alumina micro powder.

| Brand | Chemical composition(%) | α-Al2O3 | Particle size | ||||

| Al2O3 ≥ | SiO2 ≤ | Fe2O3≤ | Na2O≤ | L.O.I≤ | % ≥ | μm | |

| ACG-2A | 99.0 | 0.20 | 0.04 | 0.5 | 0.25 | 93 | 3-5 |

Ordinary Fine Powder Of Calcined Alumina

Characteristics: good sintering performance, stable line shrinkage, narrow particle size and grain size distribution.

Application: refractories, refractory binder, alumina ceramics, glass raw materials, polishing raw materials.

Note: The above are typical values for reference. For your batch COA and target Calcined Alumina grade, please contact our Manufacturer team.

Processing & Surface Options

- Deagglomeration and air classification for narrow PSD.

- Optional surface treatment to improve slurry dispersion.

- Guidance for pressing, tape casting, slip casting, and extrusion.

- Support for pilot firing windows based on target density.

Packaging & Logistics

- 25 kg paper bags with PE liner.

- Palletized loading or jumbo bags (500–1000 kg) for wholesale buyers.

- OEM labeling with grade, batch number, and production date.

- Export-ready packing and logistics support.

Quality Control & Traceability

- Incoming raw material inspection and calcination monitoring.

- In-process checks for PSD, chemistry, and whiteness.

- Finished goods testing with retained samples.

- Batch traceability and COA for each shipment.

How to Choose Calcined Alumina

- Polishing: Microfine grade with narrow PSD for smooth finish.

- Ceramics: Fine to medium grades based on density and shrinkage targets.

- Refractories: Medium to coarse grades for packing and thermal stability.

- Electronics: Low-soda and low-iron grades for clean performance.

For beginners, you may also read: What Is Calcined Alumina Powder.

FAQ

What is Calcined Alumina used for?

Calcined alumina is used in polishing, ceramics, refractories, electronics, and as a functional industrial filler.

How is Calcined Alumina different from Tabular Alumina?

Calcined alumina is a fine powder designed for polishing and ceramic bodies, while tabular alumina is a coarse, sintered aggregate used mainly in refractories.

Can you supply low-soda Calcined Alumina?

Yes. Low-soda and ultra-low-soda options are available for high-performance applications.

Do you support OEM labeling and wholesale orders?

Yes. As a manufacturer and supplier, we support OEM labels, custom packing, and long-term wholesale cooperation.

Related Products & Comparisons

Contact the Manufacturer

Looking for a reliable Calcined Alumina Manufacturer and Supplier with stable Wholesale supply? Contact BanlanChem for grade selection, samples, COA, and pricing. We support OEM labels, custom PSD, and global logistics.