Calcined Alumina and Alumina: Differences, Uses & Prices Explained

What is the Difference Between Calcined Alumina and Alumina?

Calcined alumina and alumina are both derived from aluminum minerals, but their differences arise from their preparation methods, properties, and uses. Understanding these differences can help industries select the right material for their needs, such as ceramics, electronics, or refractory applications.

Calcined Alumina: Definition and Characteristics

Calcined alumina is made by heating natural aluminum hydroxide minerals to temperatures exceeding 1100 °C. This process removes water of crystallization, yielding a harder, denser material with higher thermal and chemical stability. It is ideal for ceramics, refractory materials, electronics, and polishing abrasives.

Alumina: Definition and Characteristics

Alumina is created via chemical treatments of bauxite or industrial aluminum hydroxide. It has a finer particle size, softer texture, and lower thermal resistance compared to calcined alumina. Its common applications are in ceramics, electronics, and the production of high-purity aluminum metal due to its excellent insulating properties and cost efficiency.

Applications of Calcined Alumina and Alumina

Calcined Alumina Applications

Calcined Alumina is a highly stable material with a high melting point, excellent strength, hardness, electrical resistivity, and thermal conductivity. Thanks to these properties, it is used in many industries. Here are some common applications of Calcined Alumina:

1. Electronics and Ceramics

Electronic Substrates: Calcined Alumina is ideal for making electronic substrates due to its high insulating properties and stability. It provides a strong and safe foundation for electronic components, preventing short circuits or signal interference. You can find it in mobile phones, computer motherboards, and other electronics.

Vacuum Tubes: Calcined Alumina is used in making vacuum tubes because it can tolerate very high temperatures while maintaining strength and stability. In old-style radios and TVs, vacuum tubes made from Calcined Alumina offered long life and strong performance.

2. Refractory Materials

Monolithic Refractory Materials: Calcined Alumina is added to refractory materials (such as high-alumina castables) to fill pores and make the structure denser. This improves thermal resistance and allows the material to survive harsh conditions inside steel, cement, and glass furnaces.

Shaped Refractory Materials: Calcined Alumina improves the strength and durability of shaped refractory products like corundum bricks. These bricks maintain their strength and stability even at very high temperatures, making them ideal for steelmaking and glass melting applications.

3. Wear-Resistant Materials

Ball Mill Liners: Calcined Alumina has high hardness and wear resistance, making it ideal for ball mill liners. Its use reduces wear and tear inside the mill, extending its service life and making grinding more efficient. This is valuable for industries like mining, cement, and chemicals.

Ceramic Bearings: Calcined Alumina is used in making ceramic bearings because it has low friction, high wear resistance, and strong corrosion resistance. These bearings work reliably under harsh conditions and are ideal for aerospace, automotive, and machinery applications.

4. Polishing Materials

Grinding and Polishing: Calcined Alumina is ideal for polishing jewelry, plastics, metals, and mirrors. Its fine grain ensures a smooth and shiny surface. In jewelry making, it allows jewelers to achieve beautiful finishes while preserving the quality of the piece.

Chemical Balls and Grinding Balls: Calcined Alumina is used to make chemical and grinding balls, providing better efficiency in chemical production. Its strength and consistency help achieve precise particle sizes when producing paints, inks, and pigments.

5. Other Applications

Glass and Ceramics: Calcined Alumina improves the strength, hardness, and thermal resistance of glass and ceramics. It is used in making premium glass products and high-performance ceramics like tableware and kitchen accessories.

Lithium Battery Separators: Calcined Alumina is used in lithium battery separators to improve thermal resistance, mechanical strength, and ion conductivity. This improves the safety and performance of lithium batteries used in electric cars and electronics.

Alumina Applications and Uses

Alumina is a highly versatile material used across many industries. Thanks to its high melting point, strong wear resistance, and chemical stability, it plays an important role in manufacturing, electronics, ceramics, and more. Here are the main application areas of alumina:

1. Metal Smelting

Producing Aluminum Metal: Alumina is the primary raw material for making metal aluminum. Through electrolysis, alumina is transformed into aluminum metal, which is used extensively in aerospace, automotive, construction, electronics, and other industries.

2. Refractory Materials

Refractory Bricks: Due to its high melting point, strong hardness, and resistance to heat and chemicals, alumina is used to make refractory bricks like corundum bricks and high-alumina bricks. These materials are ideal for use in steel, glass, and ceramics industries, where equipment operates at very high temperatures.

Refractory Tubes and Crucibles: Alumina is used in making refractory tubes and crucibles for melting, sintering, and other high-temperature processes. Its resistance to deformation and damage makes it ideal for metal smelting, glass making, and ceramics production.

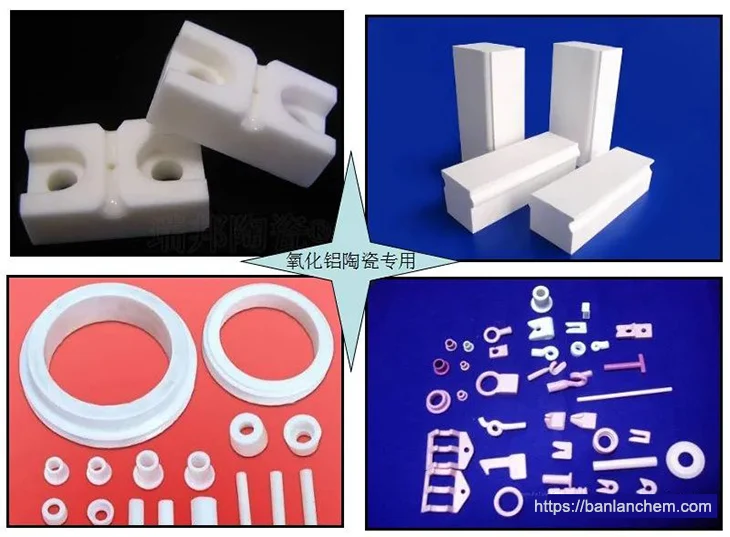

3. Ceramics

Ceramic Products: Alumina is an important raw material for making a range of ceramics, including tableware, decorative ceramics, and industrial components. Its high strength, hardness, wear resistance, and corrosion resistance make it valuable for industries like machinery, electronics, and chemicals.

Electronic Ceramics: High-purity alumina is used in making electronic ceramics such as substrate boards, ceramic packaging materials, and vacuum tube housings. It is ideal for tape casting, dry pressing, isostatic pressing, hot pressing, and injection molding for precision ceramics used in electronics and other fields.

4. Abrasives and Polishing Materials

Grinding Materials: Alumina powder is ideal for grinding metal and nonmetal surfaces due to its high hardness and wear resistance. In machining, it is used to grind metal parts and improve surface finish and precision.

Polishing Materials: Alumina polishing powder is used for polishing glass, ceramics, plastics, and metals, providing a smooth and shiny surface. It is common in optical instruments, electronics, automotive components, and other precision industries.

5. Catalysis

Catalyst Supports: Alumina has a porous structure, a high surface area, and a specific acid-base nature, making it an ideal catalyst support. It is used in petrochemical and chemical industries to carry active ingredients such as precious metals and transition metal oxides for catalyzing petroleum refining, hydrogenation, cracking, and other chemical reactions.

Catalyst Material: Alumina itself can also work as a catalyst in certain organic synthesis reactions, acting as an acid catalyst to speed up reaction rates and improve efficiency.

6. Other Applications

Flame Retardant Materials: Alumina is used as a flame-retardant additive in polymers and rubber, making cables and other materials more fire-resistant. This is valuable for industries such as construction, transportation, and electrical equipment manufacturing.

Adsorbent Materials: Thanks to its strong adsorption capacity, alumina is used to remove impurities from gases and liquids. In petroleum refining, it adsorbs sulfur and nitrogen compounds, and in water treatment, it captures heavy metal ions and organic pollutants, making water cleaner and safer.

Artificial Gemstones: High-purity alumina is used to create synthetic gemstones like corundum, ruby, and sapphire. These gemstones have physical and chemical properties similar to natural stones, making them popular in jewelry, optical instruments, and laser technologies.

Differences in Production and Cost

Calcined Alumina Production and Cost Factors

Calcined alumina is more expensive due to its high-temperature processing and superior thermal and chemical stability. Its cost depends on raw material quality, calcination temperatures, and overall production quality. As a result, calcined alumina is ideal for high-performance applications where durability and resistance are critical.

Alumina Production and Cost Factors

Alumina is more cost-effective due to its chemical production process, making it ideal for general uses in electronics, ceramics, and other industries. Its cost depends on market supply and demand, production volume, and quality specifications required by the end application.

Choosing Between Calcined Alumina and Alumina

- Calcined Alumina is ideal for high-temperature, high-performance, and wear-resistant applications such as refractories, electronics, and ceramics.

- Alumina is a cost-effective choice for electronics, chemical, and general ceramics applications due to its fine particle size and excellent insulating properties.

Calcined Alumina Faq

Q: Is calcined alumina safe for use in ceramics?

A: Yes, calcined alumina is highly stable and ideal for ceramics due to its thermal and chemical resistance.

Q: Can alumina be used in electronics?

A: Absolutely. Alumina is used extensively in electronics due to its excellent insulating properties and fine particle size.

Q: Why Choose Calcined Alumina?

A: Calcined Alumina is a highly versatile material. Its strength, thermal resistance, and durability make it ideal for electronics, refractory materials, wear-resistant ceramics, polishing applications, and lithium batteries. Its unique properties help industries worldwide build stronger, safer, and more efficient products.