Is Alumina Powder the Same as Aluminum Oxide?

Many buyers and engineers ask the same question: Is alumina powder the same as aluminum oxide? The short answer is: alumina is aluminum oxide in most industrial contexts, and alumina powder is a powder form of aluminum oxide (Al2O3). But in real purchasing and production work, the details matter. Different grades, particle sizes, purity levels, and processing routes can change performance. This guide explains the meaning, the differences in daily use, and how to choose the right material for your application.

Contents

- Quick Answer: Alumina Powder vs Aluminum Oxide

- Definitions and Common Names

- Chemical Formula and Structure

- Powder Form vs Material Family

- Types of Aluminum Oxide (Alumina) Used in Industry

- Key Properties That Affect Performance

- Applications: Where Alumina Powder Is Used

- How to Choose the Right Alumina Powder

- Quality Control, Packaging, and Export Documents

- FAQs

Quick Answer: Alumina Powder vs Aluminum Oxide

So, is alumina powder the same as aluminum oxide? In chemistry, yes: alumina is another name for aluminum oxide (Al2O3). In business, “alumina powder” usually means aluminum oxide supplied in powder form for industrial use.

However, people often use these terms in different ways:

- Aluminum oxide can mean a broad material family, including different crystal phases and forms (powder, granules, ceramics, coatings).

- Alumina powder usually points to powder grades with defined particle size, purity, and performance for a specific process.

If you are buying for polishing, ceramics, refractories, or technical parts, you should focus on: purity, particle size, phase (alpha/gamma), and consistent quality. That is what decides real results.

Definitions and Common Names

To answer is alumina powder the same as aluminum oxide clearly, we need simple definitions.

- Aluminum oxide: a chemical compound made from aluminum and oxygen. The common formula is Al2O3.

- Alumina: a common industrial name for aluminum oxide. In many markets, “alumina” and “aluminum oxide” mean the same thing.

- Alumina powder: aluminum oxide in powder form, often made and classified for industrial processes.

You may also see these names:

- Al2O3 powder

- High purity alumina powder

- Calcined alumina

- Activated alumina

- Tabular alumina

If you are a buyer, “alumina powder” usually means the supplier can give a controlled specification and stable batches. That is why many Manufacturer, Supplier, Factory, and Wholesale listings use “alumina powder” in product pages.

Chemical Formula and Structure

Aluminum oxide has the chemical formula Al2O3. But the material can exist in different phases. These phases can impact hardness, density, surface area, and reactivity. So while the answer to is alumina powder the same as aluminum oxide is “yes” in formula, it can be “not exactly” in performance if the phase is different.

- Alpha alumina (α-Al2O3): very stable, high hardness, often used for ceramics and polishing.

- Gamma alumina (γ-Al2O3): higher surface area, more reactive, often used for catalysts and adsorbents.

Most industrial “alumina powder” products clearly state the phase or the processing method. If not, you should ask before you order.

Powder Form vs Material Family

A common reason people ask is alumina powder the same as aluminum oxide is that they see these terms used differently on different websites. Here is a practical way to understand it:

Aluminum oxide = the material name (a family name in industry).

Alumina powder = the form + specification (powder grade with size and purity).

In the same way:

- “Silicon dioxide” is a material, but “silica powder” is a form.

- “Titanium dioxide” is a material, but “TiO2 powder” is a form.

So, when you see “alumina powder,” you should expect:

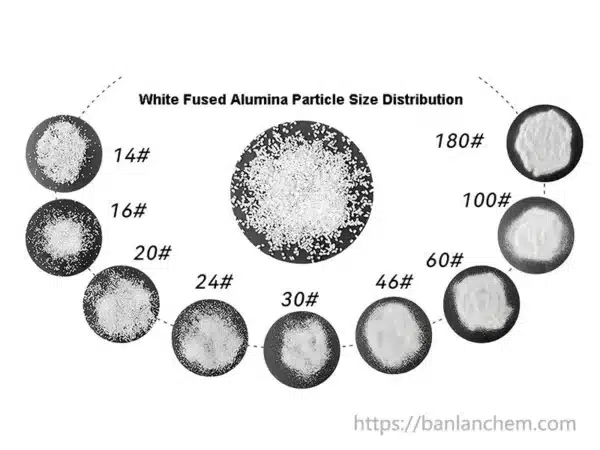

- Particle size data (D50, mesh, micron)

- Purity (Al2O3 %)

- Impurities (Na2O, Fe2O3, SiO2)

- Application notes (polishing, ceramics, refractories)

Types of Aluminum Oxide (Alumina) Used in Industry

If you want your page to rank for is alumina powder the same as aluminum oxide, you should also cover the main industry types. These types explain why one “aluminum oxide” can behave very differently from another.

1) Calcined Alumina

Calcined alumina is aluminum oxide that has been heat-treated to improve stability and reduce volatile content. It is common in ceramics, refractories, abrasives, and polishing systems. If you are sourcing for stable hardness and consistent performance, many buyers select calcined alumina.

Product reference: Calcined Alumina

2) High Purity Alumina (HPA)

High purity alumina is used for high-end applications such as advanced ceramics, electronics, and special polishing. If your process is sensitive, purity and particle control become critical.

3) Activated Alumina

Activated alumina usually refers to porous alumina with high surface area. It is used for adsorption, drying, and catalyst support. This is a case where the chemistry is still Al2O3, but the form and surface are very different.

4) Tabular Alumina

Tabular alumina is a sintered, dense alumina aggregate widely used in high-temperature refractory applications. It is not a fine powder; it is often used as an aggregate size.

Key Properties That Affect Performance

When buyers ask is alumina powder the same as aluminum oxide, what they really want to know is: “Will it work in my process?” So here are the key properties you should check.

- Purity: Higher Al2O3 content usually means better stability and fewer side effects.

- Particle size distribution: Impacts surface finish, sintering behavior, and mixing.

- Crystal phase: Alpha vs gamma matters for hardness and reactivity.

- Density: Influences packing, flow, and final part density.

- Surface area: Higher surface area can increase reactivity and binder demand.

- Impurities: Na2O and Fe2O3 can affect color and sintering.

For polishing and ceramics, a stable particle size and clean impurity control often matter more than “just Al2O3.” That is why “alumina powder” is often used as a purchasing term rather than “aluminum oxide.”

Applications: Where Alumina Powder Is Used

To rank well for is alumina powder the same as aluminum oxide, you should connect the answer to practical applications. Here are common uses where alumina powder is selected.

Polishing and Surface Finishing

- Metal polishing compounds

- Glass and optical finishing

- Ceramic polishing systems

- Final surface smoothing for technical parts

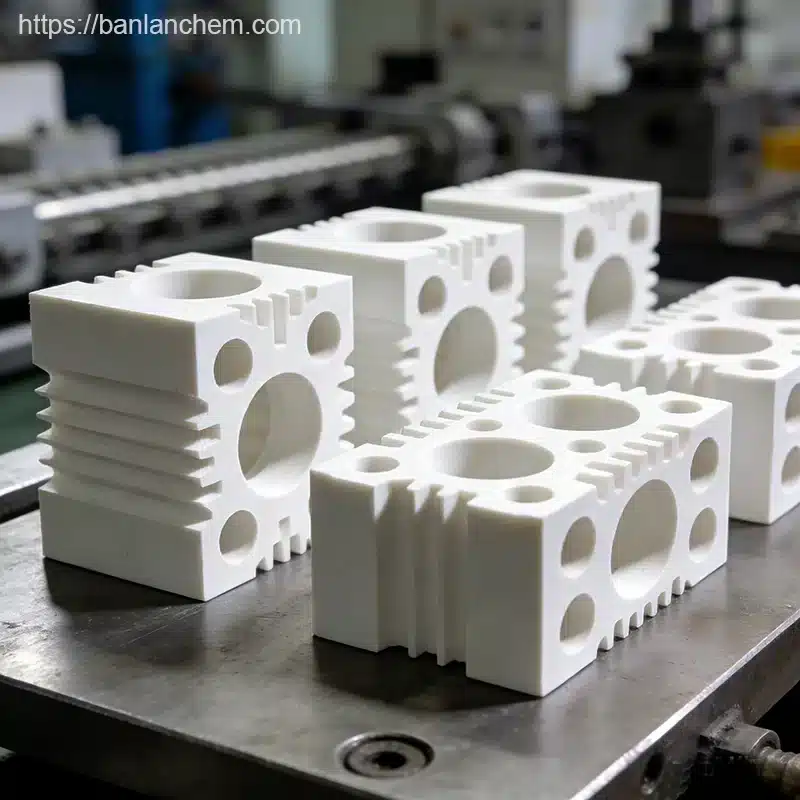

Ceramics and Advanced Ceramics

- Structural ceramics

- Electronic substrates

- Wear-resistant parts

- Grinding media

Refractories and High-Temperature Materials

- Refractory castables

- Refractory bricks

- High-temperature linings

Abrasives

- Grinding wheels

- Sandpaper and coated abrasives

- Abrasive blasting media (in some systems)

Coatings, Fillers, and Compounds

- Thermal spray coatings (in some grades)

- Wear-resistant coatings

- Polymer fillers for strength and heat resistance

If your main need is polishing or ceramics, you may want to review our What Is Alumina Powder Used For? and the product grade options on the Alumina Powder .

How to Choose the Right Alumina Powder

Even if the answer to is alumina powder the same as aluminum oxide is “yes” in chemistry, you still need to choose the right grade. Use this simple checklist.

Step 1: Define your application

- Polishing

- Ceramics

- Refractories

- Abrasives

- Coatings or fillers

Step 2: Confirm key specifications

- Al2O3 content (%)

- Particle size (D50, micron, mesh)

- Crystal phase (alpha/gamma)

- Na2O / Fe2O3 limits

- Moisture and loss on ignition (LOI)

Step 3: Match the grade to your process

- Polishing: controlled fine size, clean impurities, stable dispersion.

- Ceramics: alpha phase, stable sintering behavior, consistent PSD.

- Refractories: suitable particle mix, high temperature stability.

Step 4: Choose a reliable supplier

If you buy from a trusted Manufacturer or Supplier, you can reduce batch variation risk. A strong Factory can also support custom specs and stable lead times. For bulk orders, many customers ask for Wholesale supply and export-ready documents.

Quality Control, Packaging, and Export Documents

For industrial orders, the supplier’s document set matters. Before you place an order, confirm the supplier can provide:

- COA (Certificate of Analysis)

- MSDS / SDS (Safety Data Sheet)

- Specification sheet (typical values and limits)

- Batch traceability information

Common packaging options include:

- 25 kg bag

- 1 ton jumbo bag (for bulk shipping)

- Customized packaging for special logistics needs

If you want stable industrial supply, working with a direct Manufacturer, Supplier, or Factory can reduce risk in production. Wholesale buyers also prefer consistent quality over a “one-time low price.”

FAQs

1) Is alumina powder the same as aluminum oxide for polishing?

In most cases, yes. Alumina powder used for polishing is aluminum oxide in powder form. But polishing results depend on particle size control, purity, and dispersion behavior. So you should choose a grade made for polishing.

2) Is alumina powder the same as aluminum oxide in ceramics?

In ceramics, alumina powder is still aluminum oxide, but the phase and particle distribution matter a lot. Alpha alumina is common for advanced ceramics. Calcined alumina is also widely used for stable ceramic processing.

3) Can I use any aluminum oxide powder as alumina powder?

Not always. Some aluminum oxide products are made for abrasives or catalysts, not for ceramic sintering or fine polishing. Always confirm the specification and the target application.

4) Why do suppliers use the term “alumina powder” instead of “aluminum oxide”?

Because “alumina powder” often implies a controlled industrial grade with defined particle size and purity. It also matches how many buyers search online. That is why “alumina powder” is common in manufacturer and wholesale listings.

5) How do I request a quote?

For industrial inquiries, it helps to share your target application, required particle size, and purity needs.

If you still ask is alumina powder the same as aluminum oxide, remember: the chemistry is the same, but industrial performance depends on grade, purity, and particle size control. Choosing the right supplier and specification is the key to stable results.