Tabular Alumina in Refractory Castables: Properties, Benefits, and Applications

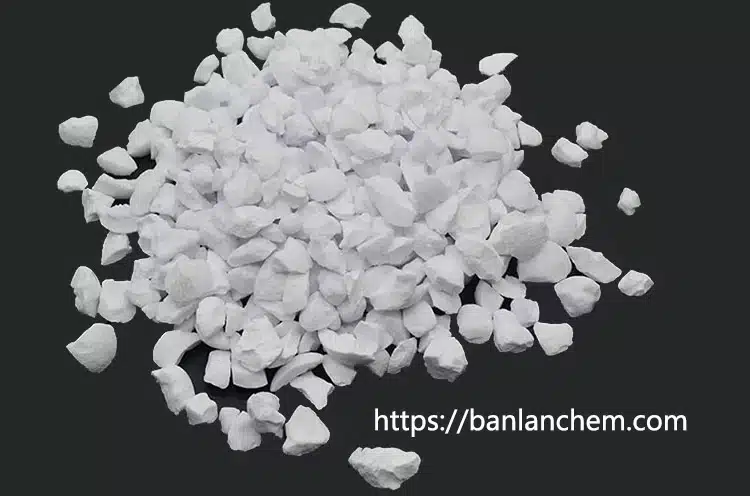

Tabular alumina is a high-purity sintered alpha alumina that plays a critical role in modern refractory castable formulations. Known for its high density, low porosity, and exceptional thermal performance, it is widely used in steel, cement, and glass industries where materials must withstand extreme temperatures and mechanical stress.

What is Tabular Alumina?

Tabular alumina is produced by sintering high-purity alumina powder at ultra-high temperatures—typically above 1900°C—without any additives. This process creates a fully crystalline alpha-alumina structure with minimal porosity and superior mechanical strength.

Because of its purity and physical characteristics, tabular alumina has become an essential raw material for high-performance refractory castables that require outstanding thermal shock resistance and long service life.

Key Properties of Tabular Alumina

- High Purity: Over 99.5% Al₂O₃, ensuring chemical stability in harsh environments.

- Low Porosity: Dense structure minimizes slag penetration and enhances corrosion resistance.

- Thermal Stability: Withstands temperatures above 1800°C without deformation.

- Excellent Mechanical Strength: Provides outstanding resistance to abrasion and thermal shock.

- Chemical Inertness: Suitable for contact with aggressive slags and alkalis.

Learn the difference between Alumina Trihydrate and Tabular Alumina to better understand their unique roles in industrial applications.

Role of Tabular Alumina in Refractory Castables

1. Improving Thermal Shock Resistance

Refractory castables used in steel and cement kilns are exposed to rapid temperature changes. Tabular alumina’s dense structure helps minimize cracks caused by thermal cycling, extending the lifespan of linings and reducing maintenance costs.

2. Enhancing Mechanical Strength

In heavy-duty applications such as ladle linings and tundish working linings, high-strength castables are essential. Tabular alumina provides the compressive strength and abrasion resistance required for these demanding conditions.

3. Reducing Slag Penetration

Slag attack is one of the main causes of refractory wear. The low porosity of tabular alumina acts as a barrier, reducing slag infiltration and preventing premature failure of castable linings.

4. Optimizing Flowability in Castables

Due to its well-defined particle size distribution, tabular alumina improves the packing density of castable mixes. This results in better flowability, reduced water demand, and improved final strength of the refractory material.

Applications of Tabular Alumina in Refractory Industries

- Steel Industry: Ladle linings, tundish working linings, and slide gate plates.

- Cement Industry: Burner pipes, kiln nose rings, and preheater linings.

- Glass Industry: Regenerators, throat blocks, and crown linings.

- Non-Ferrous Industry: Smelting and holding furnaces.

For related materials, see calcined alumina polishing applications that complement tabular alumina in certain refractory solutions.

Advantages of Using Tabular Alumina

Compared with other alumina-based aggregates, tabular alumina provides:

- Superior resistance to thermal cycling and mechanical stress.

- Better corrosion resistance against slags and alkalis.

- Longer service life of refractory linings.

- Consistent performance in high-temperature environments.

Compare this material with calcined alumina to choose the best option for your refractory needs.

Conclusion

Tabular alumina is a crucial component in high-quality refractory castables. Its unique properties, including high density, purity, and thermal stability, make it the preferred choice for industries requiring durable and reliable refractory solutions. By incorporating tabular alumina into castable formulations, manufacturers can achieve improved performance, reduced downtime, and enhanced cost efficiency.

Explore our full range of alumina materials for industrial use, or choose Banlanchem, a trusted Aluminum Hydroxide & Alumina Manufacturer for consistent quality and reliable supply.