Tabular Alumina Uses in Grinding & Refractories: Properties and Selection Guide

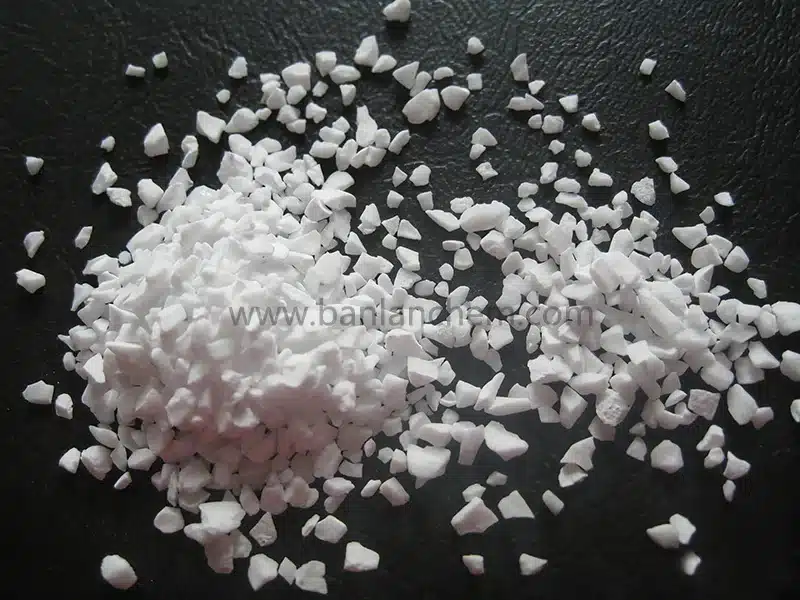

Tabular alumina is a high-purity, high-density α-Al2O3 material known for its low porosity and mechanical strength. Because of its reliability under heat and load, engineers increasingly specify tabular alumina for grinding tools and tabular alumina for refractories where predictable performance matters.

What Is Tabular Alumina?

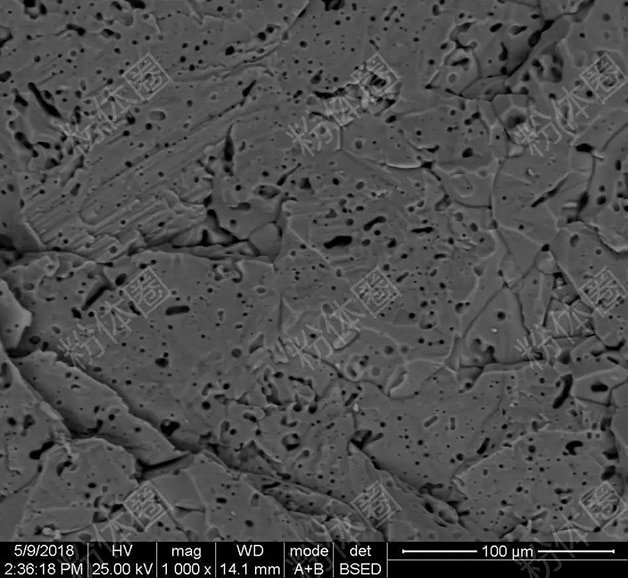

Tabular alumina is produced from purified alumina sintered at high temperatures to form well-developed α-Al2O3 crystals. The result is a dense, fully shrunk structure with minimal open porosity, superior dimensional stability, and strong resistance to wear and thermal shock.

Compared with common calcined alumina, the tabular microstructure delivers better retention of strength at temperature—one reason it performs so well in grinding wheels, refractory linings, and other high-duty applications.

Tabular Alumina Properties: Why It Is Indispensable

High Purity and High Density

Typical grades feature very high Al2O3 content and controlled impurities. High bulk density and low porosity improve mechanical reliability and thermal shock resistance in both tools and linings.

Wear Resistance for Long Service Life

Grain integrity and hardness support consistent cutting behavior. In practice, this means grinding wheels keep their form longer and deliver predictable finishes across production runs.

Chemical Stability and Thermal Shock Resistance

Tabular alumina withstands rapid heat-up and cool-down cycles and resists corrosive atmospheres—critical advantages in furnaces, kilns, and high-energy grinding environments.

Tabular Alumina Uses in Grinding and Refractories

Tabular Alumina for Grinding Wheels (Diamond & CBN)

In bond systems for diamond and CBN grinding wheels, tabular alumina contributes to a stable matrix with strong bonding and good thermal management. High purity and density help reduce wheel wear and maintain shape when grinding hard, brittle materials such as ceramics, glass, and advanced composites.

Functional Filler for Resin-Bonded Tools

As a filler in resin-bonded grinding and polishing tools, tabular alumina supports performance at elevated temperatures, improving tool life and ensuring consistent removal rates and surface quality.

Tabular Alumina for Refractory Linings

In shaped and unshaped refractories, tabular alumina raises lining durability through better thermal shock resistance and mechanical strength. This reduces cracking during thermal cycling and helps linings maintain integrity under slag attack and changing atmospheres.

How It Compares with Other Alumina Materials

- Tabular Alumina: dense, fully shrunk α-alumina; excellent for structural strength, wear, and thermal shock resistance.

- Aluminium Hydroxide: widely used as a halogen-free flame retardant filler; releases water upon decomposition and serves different roles than tabular alumina.

- White Fused Alumina: electric-arc fused alumina used as a premium abrasive and refractory raw material; complements tabular alumina in specific formulations.

Selection Guide: Choosing the Right Tabular Alumina

Grain Size and Distribution

For grinding wheels, finer fractions can help build a tighter bond structure and smoother finish. For refractories and structural parts, coarser grains improve impact resistance and maintain permeability control.

Purity and Additive Compatibility

Confirm impurity limits for sensitive applications and ensure compatibility with your bond or matrix chemistry. Additives may be used to tune rheology, sintering behavior, or thermal expansion.

Operating Conditions

Match the grade to service temperature, thermal cycling frequency, and atmospheric conditions. These parameters influence grain retention, bond health, and overall lifetime.

Processing Notes for Consistent Results

Mixing and Homogeneity

Uniform distribution of tabular alumina across the bond or castable matrix improves hardness consistency and reduces local stress points that can shorten service life.

Forming, Curing, and Sintering

Follow recommended pressures and thermal profiles to lock in density and microstructure. Controlled heating and cooling help preserve thermal shock resistance in both wheels and linings.

Quality Checks

Monitor density, porosity, and dimensions. For grinding wheels, verify balance, bond strength, and wear patterns; for refractories, check cold crushing strength and thermal shock performance.

FAQ: Tabular Alumina Properties & Uses

What are the main tabular alumina properties?

High purity, high density, low porosity, excellent mechanical strength, wear resistance, chemical stability, and strong thermal shock resistance—ideal for grinding and refractory service.

Why use tabular alumina for grinding wheels?

It helps wheels keep their form, cut predictably, and manage heat effectively, especially in diamond and CBN bond systems for ceramics, glass, and composites.

Why specify tabular alumina for refractory linings?

Its structure handles rapid thermal cycling and harsh atmospheres, improving lining life and reducing unplanned maintenance.

How does it relate to other alumina products?

It complements materials like White Fused Alumina (abrasive/refractory) and differs from Aluminium Hydroxide (flame retardant filler). Selection depends on end-use goals.

With its balanced performance under heat and load, tabular alumina has become a preferred choice for grinding wheels and refractory linings. Understanding tabular alumina properties and matching grade to service conditions will help you achieve stable processes, longer tool life, and lower total cost of ownership.