Alumina powder uses in ceramics are widely seen in modern industrial and technical ceramic production. Alumina powder is used to improve strength, wear resistance, and thermal stability of ceramic materials. This article explains how alumina powder is used in ceramics, why it is important, and how manufacturers apply it in real production.

For a full overview of all alumina powder uses across different industries, you can refer to our main guide.

- 1. Understanding Alumina Powder Uses in Ceramics

- 2. Common Questions About Alumina Powder Uses in Ceramics

- 3. Benefits of Using Alumina Powder in Ceramics

- 4. How to Use Alumina Powder in Ceramic Production

- 5. Practical Results from Ceramic Applications

1. Understanding Alumina Powder Uses in Ceramics

To understand alumina powder uses in ceramics, we should first look at the role of alumina in ceramic materials. Alumina powder is aluminum oxide in fine particle form. It is known for hardness, heat resistance, and chemical stability. These properties make it suitable for ceramic manufacturing.

In ceramic production, alumina powder is often used as:

- A main raw material for alumina ceramics

- An additive to improve mechanical strength

- A component to increase wear resistance

- A material to improve high-temperature performance

Ceramic manufacturers in China and other regions rely on alumina powder uses in ceramics for both structural and functional ceramic products. Different grades are selected based on purity and particle size.

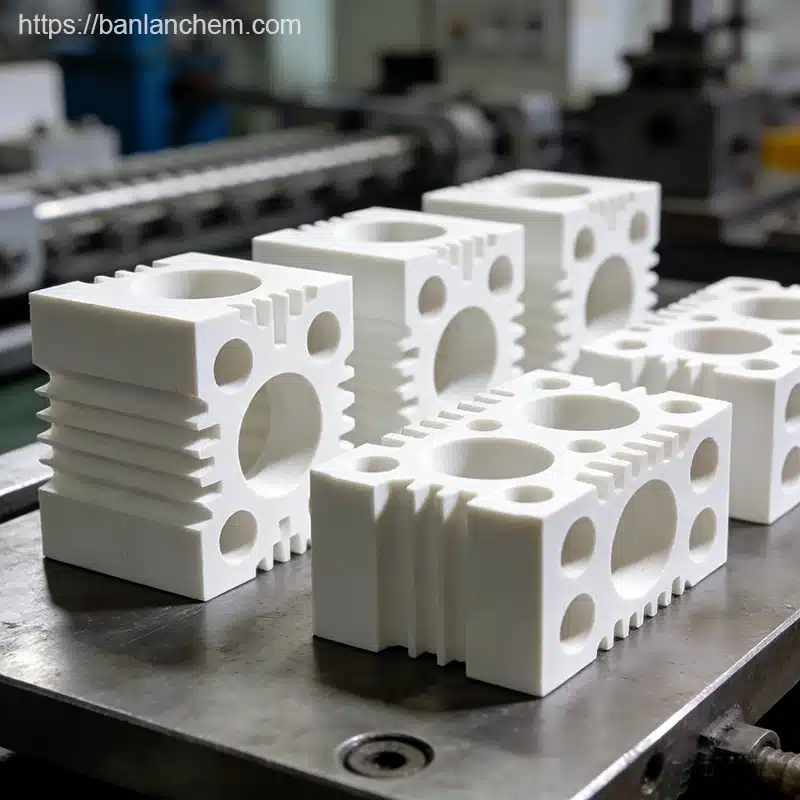

Common ceramic products made with alumina powder include:

- Wear-resistant ceramic parts

- Ceramic tubes and rods

- Ceramic liners and sleeves

- Industrial ceramic components

- High-purity technical ceramics

2. Common Questions About Alumina Powder Uses in Ceramics

Question 1: Why is alumina powder widely used in ceramic materials?

One key reason for alumina powder uses in ceramics is its stable performance under harsh conditions. Alumina powder does not soften easily at high temperature. It also resists wear and chemical attack. These features help ceramic products last longer.

In addition, alumina powder can be processed easily. It can be mixed, pressed, and sintered. This flexibility supports large-scale ceramic production.

The suitability of alumina powder for ceramic applications is closely related to alumina bonding. The strong ionic bonding between aluminum and oxygen atoms in aluminum oxide creates a rigid crystal structure, which directly contributes to the high hardness, thermal stability, and wear resistance required in advanced ceramic products.

In some ceramic applications, buyers also compare alumina powder with aluminum hydroxide. If you want to clearly understand the material differences, you can read our guide on the difference between alumina powder and aluminum hydroxide .

Question 2: Does particle size affect alumina powder uses in ceramics?

Yes, particle size plays an important role in alumina powder uses in ceramics. Fine particles improve sintering. They help achieve higher density and smoother surfaces. Coarser particles may improve flow and packing behavior.

That is why ceramic factories often test different grades before full-scale production. Choosing the right particle size reduces defects and waste.

3. Benefits of Using Alumina Powder in Ceramics

There are clear advantages behind alumina powder uses in ceramics. These benefits explain why alumina ceramics are widely used in industrial and technical fields.

Main benefits include:

- High mechanical strength for load-bearing parts

- Excellent wear resistance for abrasive environments

- Thermal stability at high temperatures

- Electrical insulation for technical ceramics

- Long service life in demanding conditions

Because of these benefits, alumina powder uses in ceramics are common in mining, metallurgy, electronics, and machinery. Factories prefer alumina ceramics to reduce downtime.

From a cost perspective, alumina powder also offers value. Stable quality reduces production loss. Wholesale supply from China helps control raw material cost.

4. How to Use Alumina Powder in Ceramic Production

Understanding how to apply alumina powder uses in ceramics step by step helps improve production efficiency. Below is a general process used by many ceramic manufacturers.

Step 1: Select the Right Alumina Powder Grade

Different ceramic products require different grades. Factors to consider include purity, particle size, and consistency between batches.

You can check available options on our alumina powder product page.

Step 2: Mixing and Formulation

The selected alumina powder is mixed with binders and additives. Uniform mixing is important. It ensures stable performance during forming and sintering.

- Control moisture content

- Ensure even particle distribution

- Avoid contamination

Step 3: Forming Process

Forming methods depend on product shape and size. Common methods include pressing, extrusion, and casting. Each method affects final ceramic properties.

Step 4: Sintering and Firing

Sintering is a key step for alumina powder uses in ceramics. High temperature firing bonds particles together. Proper temperature control is critical.

- Too low temperature reduces strength

- Too high temperature may cause deformation

Step 5: Quality Inspection

After firing, ceramic parts are inspected. This includes size, density, strength, and surface quality. Reliable manufacturers always keep records.

5. Practical Results from Ceramic Applications

Result 1: Improved Wear Resistance

Many factories report longer service life after adopting alumina powder uses in ceramics. Wear-resistant ceramic parts reduce replacement frequency. This lowers maintenance cost.

Result 2: Stable Performance at High Temperature

In furnace and kiln environments, ceramic components made with alumina powder maintain shape and strength. This improves production safety.

Result 3: Better Product Consistency

By sourcing alumina powder from a reliable Manufacturer and Supplier, ceramic factories achieve stable batch quality. This is especially important for export products.

Alumina Powder Manufacturer, Supplier, Factory, Wholesale

Choosing the right partner is essential for successful alumina powder uses in ceramics. A professional Manufacturer ensures quality control. An experienced Supplier supports technical needs. A real Factory provides stable production capacity.

At BanlanChem, we offer alumina powder from China with stable quality. We support ceramic manufacturers with Wholesale supply, export packing, and technical documents.

If you are planning ceramic production or material sourcing, understanding alumina powder uses in ceramics and working with the right supplier can improve long-term results.