Aluminum vs Alumina: What’s the Difference & Industrial Applications

Aluminum vs alumina is a common topic in industrial materials sourcing. Many buyers see similar names but very different performance results. Although aluminum powder and alumina powder sound alike, they are not the same material.

They differ in appearance, chemical structure, physical properties, and industrial applications. Understanding aluminum vs alumina helps manufacturers, suppliers, and OEM/ODM buyers select the right material.

Table of Contents

- Aluminum vs Alumina: Basic Overview

- Appearance Differences

- Chemical Composition

- Physical and Chemical Properties

- Industrial Applications of Aluminum Powder

- Industrial Applications of Alumina Powder

- Aluminum vs Alumina: Key Differences

- How to Choose the Right Material

- Manufacturer, Supplier & OEM/ODM Guide

- Conclusion

Aluminum vs Alumina: Basic Overview

The core difference in aluminum vs alumina lies in material type. Aluminum is a metal. Alumina is a ceramic oxide.

Aluminum powder is made from metallic aluminum (Al). Alumina powder is aluminum oxide with the formula Al2O3.

This basic distinction leads to major differences in conductivity, reactivity, and heat resistance. That is why aluminum vs alumina selection is critical in industrial production.

In industrial sourcing, aluminum vs alumina is closely related to downstream materials such as alumina powder and aluminum hydroxide, which are widely supplied by professional manufacturers and suppliers.

Appearance Differences

Aluminum powder has a clear metallic appearance. It looks silver-gray or silvery white. The particles strongly reflect light.

- Metallic luster

- High reflectivity

- Flake, spherical, or irregular particle shapes

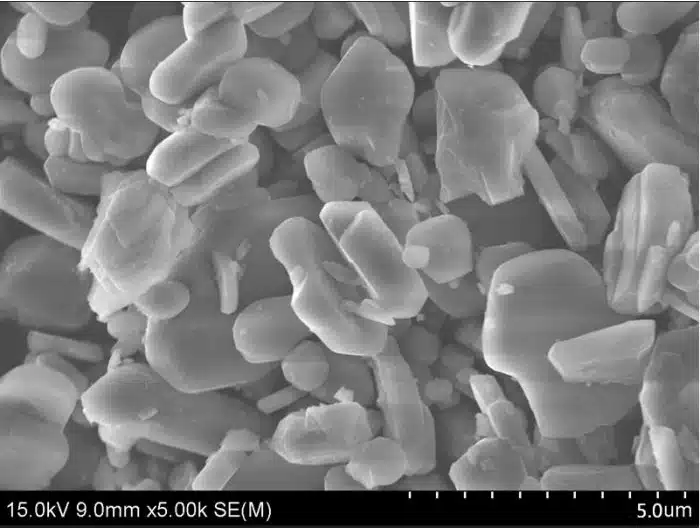

Alumina powder looks very different. It is white or light gray. There is no metallic shine.

- Matte surface

- Fine micro or nano particle size

- Uniform and stable structure

In most cases, aluminum vs alumina can be visually distinguished at first glance.

Chemical Composition

Aluminum powder consists mainly of elemental aluminum. It is chemically active.

Alumina powder is aluminum oxide. Oxygen atoms bond strongly with aluminum atoms.

This oxygen bonding makes alumina very stable. It also removes metallic conductivity. This is one of the most important differences in aluminum vs alumina.

The stability of alumina mainly comes from the strong aluminum–oxygen bonding structure. For a deeper explanation of how different bonding types affect alumina properties and performance, you can read our detailed article: Alumina Bonding Types, Properties and Uses .

Physical and Chemical Properties

Aluminum Powder Properties

- Excellent electrical conductivity

- High thermal conductivity

- High chemical activity

- Melting point around 660°C

- Lightweight and reflective

When exposed to air, aluminum powder oxidizes easily. A thin oxide film forms on the surface. This film offers limited corrosion protection.

However, strong acids or alkalis can damage this oxide layer. This limits aluminum powder use in harsh chemical environments.

Alumina Powder Properties

- Excellent chemical stability

- Strong resistance to acids and alkalis

- Mohs hardness about 9

- High wear resistance

- Melting point around 2050°C

Alumina is chemically inert in most environments. It remains stable under extreme heat. These properties explain why alumina is widely used in ceramics and refractories.

Due to its high purity and thermal stability, alumina powder used in industrial applications is often supplied in different grades. You can learn more about calcined alumina for ceramics, refractories, and polishing applications.

Industrial Applications of Aluminum Powder

Aluminum powder is used mainly for its metallic behavior and energy release. It plays an important role in many industrial sectors.

Metallurgy and Welding

Aluminum powder is a key ingredient in thermite reactions. These reactions generate very high temperatures.

- Railway track welding

- Steel structure repair

- Foundry and casting processes

In these applications, aluminum powder reacts with metal oxides. The heat produced melts and joins metals.

Fuels and Pyrotechnics

Because of its high reactivity, aluminum powder is widely used as a fuel component.

- Rocket propellants

- Explosives

- Fireworks and ignition agents

Its high calorific value makes it ideal for energy-intensive reactions.

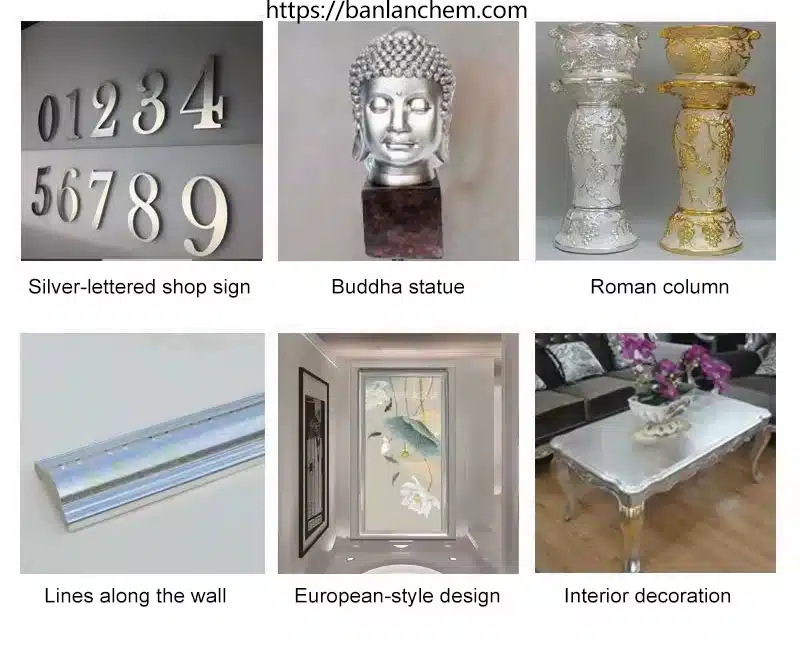

Paints and Pigments

Aluminum powder is also used in coatings. It provides brightness and reflectivity.

- Silver paints

- Decorative coatings

- Reflective and protective paints

In some industrial systems, aluminum-based materials are used together with alumina-based products. For example, aluminum powder may be combined with tabular alumina in refractory and high-temperature formulations supplied by factory-direct wholesalers.

Industrial Applications of Alumina Powder

Alumina powder is mainly used as a non-metallic engineering material. Its strength and stability define its value.

Ceramics and Refractories

- Industrial ceramics

- Refractory bricks

- Furnace linings

Alumina withstands extreme temperatures and mechanical wear. It is ideal for high-temperature industrial environments.

Electronics and Electrical Applications

- Electrical insulation substrates

- Heat dissipation components

- Semiconductor and microelectronics packaging

Alumina combines electrical insulation with good thermal conductivity. This balance is critical in electronic devices.

Catalyst Carrier

- Petrochemical catalysts

- Environmental protection catalysts

- Chemical reaction supports

Its porous structure and chemical inertness make alumina an ideal catalyst carrier.

Polishing and Abrasives

- Glass polishing

- Metal surface finishing

- Ceramic polishing

High hardness allows alumina to remove surface defects efficiently.

Aluminum vs Alumina: Key Differences

- Aluminum is metallic; alumina is ceramic

- Aluminum conducts electricity; alumina insulates

- Aluminum melts at low temperature; alumina resists extreme heat

- Aluminum is reactive; alumina is chemically stable

These differences explain why aluminum vs alumina cannot be used interchangeably.

If you want a deeper explanation of aluminum oxide materials, you can also read our detailed guide: What Is Alumina? Properties, Types and Industrial Uses .

How to Choose the Right Material

Choose aluminum powder if your application requires:

- High electrical or thermal conductivity

- Metallic appearance

- Energy release or chemical reactivity

Choose alumina powder if your application requires:

- High temperature resistance

- Wear and abrasion resistance

- Chemical inertness

Manufacturer, Supplier & OEM/ODM Guide

Selecting the right manufacturer or supplier is as important as choosing the material.

- Stable quality control

- Consistent particle size

- OEM/ODM customization options

- Reliable wholesale supply

As a professional industrial materials platform, Banlanchem supports global customers with aluminum and alumina material solutions. The factory-oriented supply model ensures quality, flexibility, and long-term cooperation.

Conclusion

Aluminum vs alumina is not just a naming difference. They are two completely different industrial materials.

Aluminum powder is valued for its metallic properties and reactivity. Alumina powder is valued for its stability, hardness, and heat resistance.

Understanding aluminum vs alumina helps manufacturers, suppliers, and OEM/ODM buyers make better sourcing decisions. It improves product performance and reduces application risk.