How to Choose a Reliable Aluminum Hydroxide Powder Supplier

Date: December-18-2025 Categories: News、Aluminium Hydroxide Views: 52

Choosing a reliable aluminum hydroxide powder supplier is a critical decision for manufacturers, distributors, and industrial buyers. Aluminum hydroxide powder is widely used in flame retardants, plastics, rubber, cables, ceramics, and chemicals. Product quality directly affects safety, performance, and cost control.

This guide explains how to choose a reliable aluminum hydroxide powder supplier in a clear and practical way. It is written for buyers looking for a stable manufacturer, supplier, factory, or wholesale partner for long-term cooperation.

Once a reliable supplier is selected, it is important to review detailed product specifications and supply capability. You can find full information on our aluminum hydroxide powder product page .

Table of Contents

- 1. What Is Aluminum Hydroxide Powder?

- 2. Why Choosing the Right Supplier Matters

- 3. Common Applications of Aluminum Hydroxide Powder

- 4. How to Evaluate Product Quality

- 5. Manufacturer vs Trader: Who Should You Choose?

- 6. Certifications and Technical Documents

- 7. Production Capacity and Supply Stability

- 8. Custom Grades and OEM Support

- 9. Price, Cost Structure, and Wholesale Considerations

- 10. Packaging, Logistics, and Export Experience

- 11. Why Choose BanlanChem as Your Supplier?

- 12. FAQ

1. What Is Aluminum Hydroxide Powder?

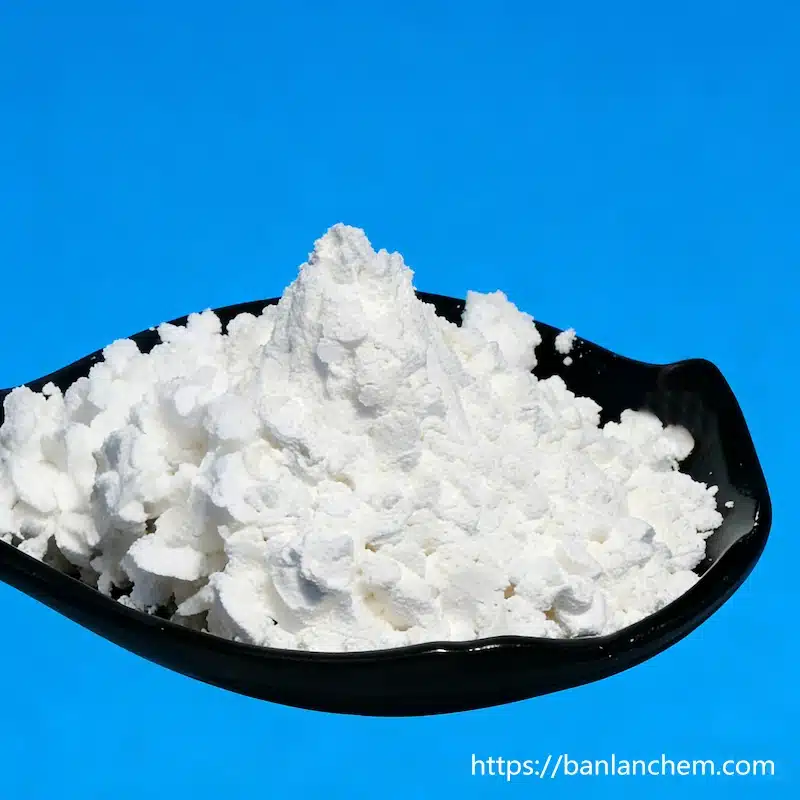

Aluminum hydroxide powder, also known as ATH, is an inorganic compound with the chemical formula Al(OH)3. It is a white powder with high purity and stable chemical properties.

It is mainly used as:

- Flame retardant filler

- Smoke suppressant

- Functional filler in plastics and rubber

- Raw material for alumina production

Aluminum hydroxide powder is also an important raw material for producing alumina products such as Calcined Alumina, which is widely used in ceramics, polishing, and advanced materials.

2. Why Choosing the Right Supplier Matters

Not all aluminum hydroxide powder suppliers are the same. Quality differences can cause serious problems in downstream production.

A reliable supplier helps you:

- Maintain consistent product performance

- Reduce production defects

- Control long-term costs

- Meet safety and regulatory requirements

For manufacturers and wholesale buyers, supplier reliability is often more important than short-term price.

3. Common Applications of Aluminum Hydroxide Powder

Understanding applications helps you choose the right grade and the right supplier.

Main application areas

- Flame retardant cables and wires

- Plastics and polymer compounds

- Rubber products

- Artificial stone and solid surface materials

- Ceramics and glass

Different applications require different particle sizes, purity levels, and surface treatments.

Related reading: What Is Aluminum Hydroxide Used For?

4. How to Evaluate Product Quality

Product quality is the first factor when choosing an aluminum hydroxide powder supplier.

Key quality indicators

- Al(OH)3 purity

- Particle size distribution

- Whiteness

- Moisture content

- Oil absorption

- Impurity control (Na2O, Fe2O3)

A professional manufacturer will provide stable data for each batch.

5. Manufacturer vs Trader: Who Should You Choose?

Many buyers ask whether to work directly with a factory or through a trader.

Working with a manufacturer

- Better price transparency

- Direct quality control

- Custom grade support

- Stable long-term supply

Working with a trader

- Lower MOQ for small orders

- Limited technical support

- Less control over production

For wholesale and OEM projects, working with a real aluminum hydroxide powder factory is usually the better choice.

6. Certifications and Technical Documents

A reliable aluminum hydroxide powder supplier should provide complete documentation.

Important documents

- COA (Certificate of Analysis)

- MSDS / SDS

- REACH compliance

- ROHS compliance

- ISO quality management certificates

These documents help buyers meet local regulations and customer requirements.

7. Production Capacity and Supply Stability

Supply stability is critical for manufacturers with continuous production.

Questions to ask a supplier

- What is your annual production capacity?

- How many production lines do you operate?

- How do you manage raw material supply?

- Can you support long-term contracts?

A strong factory can handle both regular orders and peak demand.

8. Custom Grades and OEM Support

Different customers need different aluminum hydroxide powder grades.

Customization options

- Particle size adjustment

- Surface treatment

- Low sodium grades

- Low moisture grades

OEM and ODM support is important for distributors and brand owners.

In high-temperature and refractory applications, buyers may also require Tabular Alumina, which is commonly used in steel, foundry, and kiln lining materials.

9. Price, Cost Structure, and Wholesale Considerations

Price is important, but it should not be the only factor.

What affects price?

- Raw material quality

- Production process

- Energy cost

- Quality control level

- Packaging requirements

Wholesale buyers should focus on long-term cost stability instead of short-term low prices.

10. Packaging, Logistics, and Export Experience

Packaging and logistics affect product safety and delivery time.

Common packaging options

- 25 kg paper bags

- 1-ton jumbo bags

- Customized OEM packaging

An experienced supplier understands export procedures, shipping documents, and international logistics.

11. Why Choose BanlanChem as Your Supplier?

BanlanChem focuses on aluminum hydroxide powder and alumina-based materials. As a professional manufacturer and supplier, BanlanChem supports global customers with stable quality and technical service.

Key advantages

- Stable product quality

- Multiple grades available

- OEM and wholesale support

- Export experience

- Fast technical response

12. FAQ

Q1: Is aluminum hydroxide powder the same as ATH?

Yes. ATH is the common abbreviation for aluminum trihydroxide.

Q2: Can I request samples?

Reliable suppliers usually provide samples for testing before bulk orders.

Q3: What is the typical MOQ?

MOQ depends on grade and packaging, especially for wholesale orders.

During supplier evaluation, it is also important to understand material differences. For a clear comparison between related materials, you may read What Is the Difference Between Alumina Powder and Aluminum Hydroxide .

Choosing a reliable aluminum hydroxide powder supplier requires careful evaluation of quality, production capacity, certifications, and service. A good manufacturer or factory offers more than just product supply. It offers long-term partnership.

For buyers looking for a stable aluminum hydroxide powder supplier, BanlanChem provides professional support for manufacturers, distributors, and wholesale customers worldwide.