Is alumina powder safe for industrial use? This is a common question for manufacturers, engineers, and buyers who work with aluminum oxide (alumina) powder every day. Alumina is widely used in ceramics, refractories, polishing, abrasives, coatings, and many other industrial processes. In most cases, alumina powder is handled as a stable inorganic material. However, safe use depends on the grade, particle size, dust control, and the way it is processed in a real factory environment.

This guide explains practical safety topics in clear language. It focuses on industrial handling, not consumer use. You will learn common hazards, dust exposure risks, PPE, storage rules, spill cleanup, and safe work practices that help keep production stable and compliant.

Related pages on BanlanChem: Alumina Powder, Calcined Alumina, Alumina Powder vs Aluminum Hydroxide.

Table of Contents

- What Is Alumina Powder?

- What “Safe for Industrial Use” Really Means

- Common Hazards in Factory Handling

- Dust Exposure: Inhalation Risks and Controls

- Eye and Skin Contact: Irritation and Protection

- Recommended PPE for Alumina Powder

- Safe Handling in Production: Step-by-Step

- Storage, Packaging, and Moisture Control

- Spill Cleanup and Housekeeping

- Formulation and Process Risks

- How to Use an SDS for Alumina Powder

- Buyer Checklist: Choosing a Reliable Supplier

- FAQ

- Manufacturer, Supplier, Factory, Wholesale

What Is Alumina Powder?

Alumina powder is aluminum oxide. It is often written as Al2O3. It is a white inorganic powder used in many industries. Different alumina grades are made for different purposes. For example, calcined alumina is common for ceramics, refractories, and polishing. Some grades are designed for high purity. Others are designed for specific particle size, flowability, or packing density.

Because alumina is used as a powder, most workplace safety topics are related to dust and handling. The material itself is stable, but powder behavior in a factory can create practical risks. That is why many people search is alumina powder safe for industrial use before they buy or process it.

What “Safe for Industrial Use” Really Means

When people ask is alumina powder safe for industrial use, they often mean one of these questions:

- Is alumina powder toxic?

- What happens if workers breathe in alumina dust?

- Can alumina powder irritate eyes or skin?

- What controls are needed in a plant?

- How do we store and clean up alumina safely?

In industrial settings, “safe” does not mean “no risk.” It means:

- hazards are understood and controlled

- exposure is reduced through ventilation and housekeeping

- PPE is used when needed

- storage and transport reduce contamination and moisture issues

- process steps are designed to reduce dust release

In practice, the biggest difference between a safe and unsafe operation is not the product name. It is the control system in the plant.

Common Hazards in Factory Handling

Alumina powder is widely considered a stable material. Still, several practical hazards may appear during manufacturing and processing. These hazards are common when powder is moved, poured, mixed, or milled.

- Airborne dust: dust can form during bag opening, feeding, or mixing.

- Respiratory irritation: excessive dust exposure may irritate the respiratory system.

- Eye irritation: fine particles may cause mechanical irritation.

- Skin dryness or irritation: repeated contact may cause discomfort for some workers.

- Slip hazards: spilled powder may create slippery surfaces on floors.

- Housekeeping load: poor cleanup can spread dust into nearby zones.

- Process contamination: moisture, foreign particles, or poor segregation can affect product quality.

These points explain why the question is alumina powder safe for industrial use often appears in EHS reviews and supplier audits.

Beyond safety considerations, alumina powder is also valued for its thermal stability. Its performance in elevated-temperature environments is explained in this high-temperature application overview .

Dust Exposure: Inhalation Risks and Controls

Dust exposure is the most important workplace topic for alumina powder. During normal handling, particles can become airborne. The risk level depends on particle size, feed method, and ventilation.

Where dust usually comes from

- opening bags and dumping powder into hoppers

- manual feeding into mixers or reactors

- transfer points on conveyors

- screening, milling, or blending steps

- cleanup using dry sweeping methods

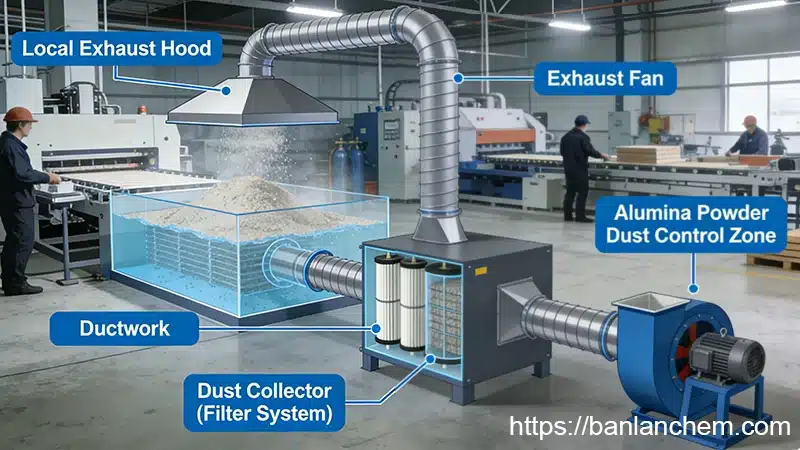

Practical controls that work

- Local exhaust ventilation: capture dust at the source.

- Enclosed feeding: use closed systems on high-throughput lines.

- Slow and controlled pouring: reduce sudden dust clouds.

- Industrial vacuum cleaning: avoid dry sweeping that raises dust.

- Defined work zones: reduce cross-contamination between processes.

In many plants, improving dust capture and cleanup procedures produces the biggest safety improvement with the lowest cost.

Eye and Skin Contact: Irritation and Protection

Alumina powder can cause mechanical irritation, especially for eyes. This is common for fine mineral powders. Eye and skin protection is simple, but it must be consistent.

Eye contact

- Fine particles may cause discomfort or redness.

- Safety goggles help prevent accidental exposure.

- Eye wash stations should be accessible in powder handling zones.

Skin contact

- Repeated contact may cause dryness or irritation for some workers.

- Gloves reduce direct contact and keep hands clean.

- Wash hands after handling powder and before eating or drinking.

Recommended PPE for Alumina Powder

PPE selection depends on dust level and work tasks. The goal is to match PPE to the exposure risk. In most plants, basic PPE is enough when engineering controls work well.

- Respiratory protection: a suitable particulate respirator when dust is present.

- Eye protection: safety goggles or glasses with side shields.

- Hand protection: work gloves to reduce contact and keep hands clean.

- Protective clothing: workwear that reduces dust transfer to clean areas.

If your plant works with multiple powders, define a PPE rule by process step and zone. This reduces confusion and improves compliance.

Safe Handling in Production: Step-by-Step

If you want a clear answer to is alumina powder safe for industrial use, look at the standard operating steps below. They are simple, but they cover the most common failure points in powder handling.

Step 1: Prepare the handling area

- Check that ventilation systems are running.

- Confirm the hopper and feed equipment are clean.

- Confirm PPE is available and used correctly.

Step 2: Open and feed bags safely

- Open bags carefully to avoid sudden dust release.

- Pour slowly and close to the hopper opening.

- Avoid shaking bags in the air.

Step 3: Mixing and processing control

- Add powder in small, controlled portions when possible.

- Use lids and covers on mixers where available.

- Reduce unnecessary manual transfers between containers.

Step 4: End-of-shift cleanup

- Use industrial vacuum systems instead of dry sweeping.

- Clean transfer points where dust collects.

- Dispose of collected dust following local rules.

These steps help improve safety and also improve process stability. Cleaner powder handling often reduces quality issues.

Storage, Packaging, and Moisture Control

Alumina powder should be stored in a dry area. Keep packaging closed when not in use. Moisture can affect flowability, feeding behavior, and final product performance. Good storage also reduces contamination risk.

Storage tips

- store in a dry, clean, and well-ventilated area

- keep bags or bulk containers sealed

- avoid direct contact with wet floors or walls

- use first-in-first-out (FIFO) inventory control

For product details and typical supply formats, see: Alumina Powder product page.

Spill Cleanup and Housekeeping

Spills are common in powder processing. The main risks are dust spread and slip hazards. Proper housekeeping is one of the most effective controls for safe operations.

Spill cleanup rules

- Wear PPE before cleanup.

- Avoid dry sweeping that can raise dust into the air.

- Use industrial vacuum systems when possible.

- Collect material into sealed containers for handling.

- Keep walkways clear and clean after cleanup.

If you want a comparison of alumina powder and ATH safety topics, read: What is the difference between alumina powder and aluminum hydroxide?

Formulation and Process Risks

In some applications, the main risks are not from the alumina itself, but from how it is used. Mixing conditions, additives, and equipment can create secondary issues.

Common formulation and process risks

- Dust release during dosing: poor feeding design increases airborne dust.

- Agglomeration: moisture and fast addition can cause clumps and unstable flow.

- Cross-contamination: shared lines can mix different grades or materials.

- Wear in equipment: alumina hardness can increase wear in some systems.

Practical engineering changes often solve these issues. For example, improved feeding design can reduce dust and improve consistency at the same time.

How to Use an SDS for Alumina Powder

An SDS helps plants define safe handling rules. It supports training, audits, and daily operations. If you are evaluating a new grade, check the SDS and confirm it matches your process conditions.

How manufacturers use SDS information

- define PPE rules by task

- set ventilation and housekeeping standards

- prepare spill response procedures

- support customer audits and compliance reviews

If you need broader alumina knowledge, you can also review: What is alumina oxide?

Buyer Checklist: Choosing a Reliable Supplier

If you are buying alumina powder, supplier quality affects both safety and process stability. A reliable supplier provides stable specs, consistent packaging, and updated documentation.

- Check whether the supplier provides current SDS and COA documents.

- Confirm typical specifications such as purity, particle size, and impurity limits.

- Confirm packaging types and handling instructions.

- Ask about batch consistency and quality control methods.

For a factory-direct supply route, you can review our alumina product categories: Alumina Powder and Calcined Alumina.

FAQ

Is alumina powder safe for industrial use?

Is alumina powder safe for industrial use? In most industrial environments, alumina powder is handled as a stable inorganic material. Safe use depends on dust control, good housekeeping, correct PPE, and process design.

What is the main safety concern with alumina powder?

The main workplace concern is dust exposure during powder handling and processing. Engineering controls and proper cleanup greatly reduce this risk.

Does alumina powder cause eye irritation?

Fine powder contact may cause mechanical irritation. Eye protection and good work practices help prevent exposure.

How should alumina powder be stored?

Store in a dry, clean, well-ventilated area. Keep packaging sealed to reduce moisture pickup and contamination.

Manufacturer, Supplier, Factory, Wholesale

Banlan is an alumina powder Manufacturer and Supplier serving industrial customers worldwide. Our Factory provides stable quality control, export-ready documents (COA/MSDS), and reliable logistics support. We offer Wholesale supply for alumina powder and calcined alumina.