Tabular Alumina for Ceramic Parts | High Purity & Stable Performance

Tabular alumina for ceramic parts is a high-purity, high-density alumina material. It is made for tough ceramic components. It helps ceramic parts stay strong. It helps them last longer in heat, wear, and corrosion.

If you make technical ceramics, kiln furniture, wear parts, or insulation parts, tabular alumina for ceramic parts is a common choice. It is also a good option when you need stable quality in mass production.

On this page, we explain what tabular alumina is. We show how it works in ceramic parts. We also share simple buying tips for engineers and buyers. If you need a trusted Manufacturer, Supplier, Factory, or Wholesale partner.

Table of Contents

- What Is Tabular Alumina?

- Why Use Tabular Alumina for Ceramic Parts?

- Key Properties That Matter

- Typical Ceramic Parts and Use Cases

- How to Choose the Right Grade

- Processing Tips for Stable Results

- Quality Control Checklist

- Packaging, Shipping, and Lead Time

- Why Choose BanlanChem

- FAQ

What Is Tabular Alumina?

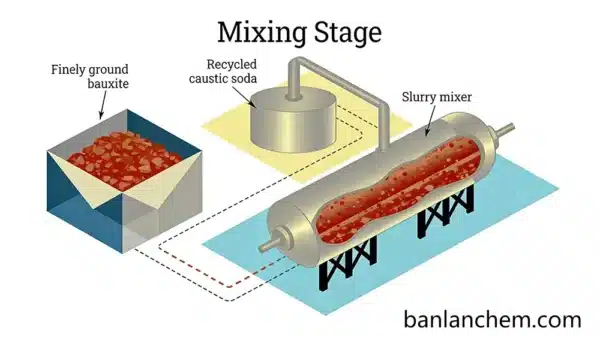

Tabular alumina is a sintered alpha alumina (α-Al2O3). It has high purity and high density. It has low porosity. This makes it strong and stable.

- High purity: supports clean ceramic microstructure.

- High density: improves strength and wear life.

- Low porosity: helps resist slag, melt, and gas attack.

- Stable chemistry: supports repeatable ceramic parts.

In many plants, tabular alumina for ceramic parts is used as a main aggregate or filler. It can be used in different particle sizes. It can also be blended with other alumina materials to reach target performance.

Visual tip: Use tabular alumina when you want a dense ceramic body and fewer open pores.

Tabular alumina for ceramic parts is a high-purity alumina material widely used in technical ceramics. As a core product, Tabular Alumina is valued for its high density, low porosity, and stable crystal structure, which help ceramic parts achieve long service life.

Why Use Tabular Alumina for Ceramic Parts?

Many ceramic parts must face heat, friction, and chemical attack. Tabular alumina for ceramic parts is popular because it balances performance and stability.

- Stable performance: less variation across batches.

- High wear resistance: good for sliding and abrasion.

- Thermal stability: good for high-temperature cycles.

- Good corrosion resistance: supports harsh service.

- Long service life: reduces replacement cost.

If your ceramic parts fail early, the root cause is often pores, weak bonding, or unstable firing results. Using tabular alumina for ceramic parts can help reduce these risks.

If you want to learn more about how tabular alumina performs in different industries, you can also read our detailed guide on Tabular Alumina Applications , which explains its role in ceramics, refractories, and high-temperature components.

Key Properties That Matter

For ceramic parts, not every property has the same weight. Below are the most useful ones to check when you source tabular alumina for ceramic parts.

- Al2O3 content: higher purity often means better stability.

- Bulk density: higher density often supports higher strength.

- Apparent porosity: lower porosity can improve corrosion resistance.

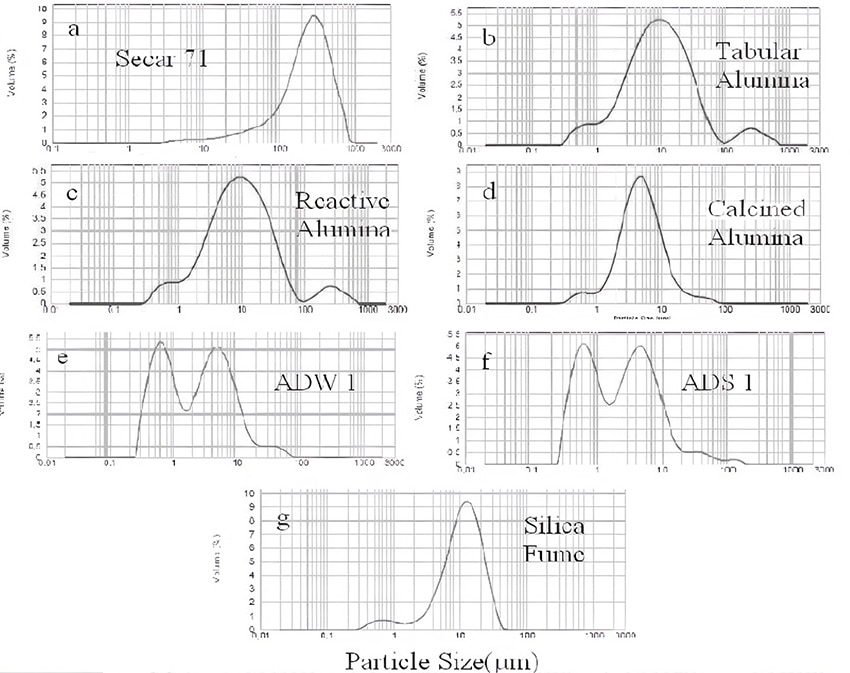

- Particle size distribution: supports packing and sintering.

- Impurity control: low Na2O and low Fe2O3 are often preferred.

Buyer note: When you compare suppliers, ask for recent COA data. Also ask for batch-to-batch limits, not only typical values.

Typical Ceramic Parts and Use Cases

Tabular alumina for ceramic parts is used in many fields. Below are common examples. You can use this list to map your part to a typical solution.

- Wear parts: liners, tiles, sleeves, and guides.

- Kiln furniture: setters, saggars, beams, and rollers.

- Thermal insulation supports: structural parts used in heat zones.

- Foundry and molten metal contact parts: selected high-alumina components.

- Electro-ceramic hardware: parts needing stable body and low contamination.

Quick idea: If your part sees both heat and wear, tabular alumina for ceramic parts is often a safer baseline choice than low-density aggregates.

How to Choose the Right Grade

Choosing tabular alumina for ceramic parts is easier when you break it into simple steps.

1) Confirm your ceramic part type

- Is it a dense wear part?

- Is it a kiln furniture part?

- Is it a thermal cycling part?

2) Decide the particle size range

- Coarse sizes: improve skeleton strength and reduce shrinkage.

- Fine sizes: fill gaps and support sintering.

- Mixed grading: often gives the best packing.

3) Set impurity limits

- For high-end ceramic parts, lower sodium is often better.

- For white or clean ceramics, low iron matters.

4) Ask for proof

- COA for each batch

- PSD report

- Bulk density and porosity report

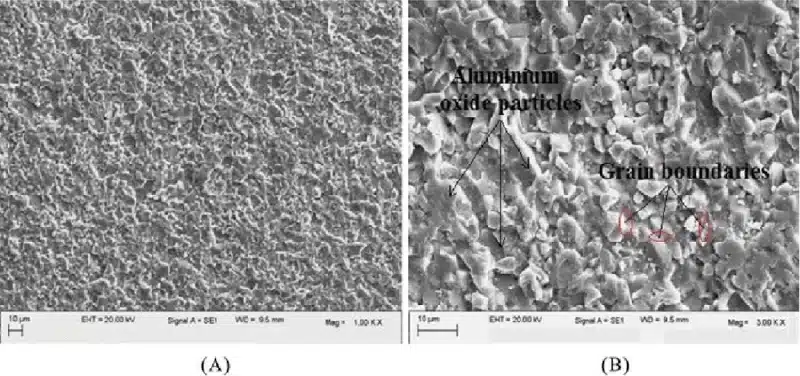

- Optional: SEM image or microstructure report (if available)

Supplier tip: A reliable Manufacturer or Factory will provide these quickly. A good Supplier will also help you match a grade to your ceramic parts.

Processing Tips for Stable Results

Even strong raw material can fail if processing is not stable. Use the tips below to get consistent ceramic parts with tabular alumina.

Mixing

- Use dry mixing first for better distribution.

- Control mixing time. Do not over-mix binder systems.

- Keep water addition stable if you use wet mixing.

Forming

- Pressing: control pressure and dwell time.

- Casting: control slurry viscosity and defoaming.

- Extrusion: keep moisture stable and avoid air pockets.

Drying

- Dry slowly for thick ceramic parts.

- Avoid fast surface drying that traps moisture inside.

Firing

- Control heating rate in binder burn-out zones.

- Keep peak temperature stable across the kiln.

- Use stable soak time for repeatable density.

Simple rule: If your defects repeat, check PSD and moisture first. If your defects change every batch, check raw material consistency and your mixing routine.

In some ceramic body designs, tabular alumina is blended with fine materials to improve packing efficiency. For this purpose, Calcined Alumina is often used together with tabular alumina for ceramic parts to balance strength, sintering behavior, and cost.

Quality Control Checklist

Use this short list when you buy tabular alumina for ceramic parts. It helps reduce risk and supports stable production.

- COA: Al2O3, Na2O, Fe2O3, SiO2, CaO (as needed).

- PSD: match your target curve.

- Bulk density: check typical and min limits.

- Apparent porosity: check typical and max limits.

- Stability: batch-to-batch control policy.

- Packaging: moisture-proof and clean bags.

Wholesale buyers: If you buy in larger volume, ask for one retained sample per batch. This helps if you need traceability later.

For ceramic manufacturers working with different formulations, Alumina Powder is another important material choice, especially for fine ceramic parts that require controlled particle size and clean chemistry.

Packaging, Shipping, and Lead Time

Packaging matters because ceramic parts need clean raw materials. Poor packaging can add moisture or contamination.

- Common packaging: 25 kg bags, 1 MT big bags, or custom packing.

- Moisture control: use inner liners and sealed pallets.

- Label info: grade, batch number, net weight, and date.

- Shipping terms: FOB, CIF, or other terms as required.

Factory note: For regular production, keep a safety stock plan. It helps you avoid urgent changes in raw material supply.

Why Choose BanlanChem

BanlanChem supports customers who need tabular alumina for ceramic parts with stable performance. We work with ceramic plants, refractory users, and industrial buyers who value clean material and repeatable results.

- Manufacturer mindset: we focus on stable quality and clear specs.

- Supplier support: we help match grades to real ceramic parts.

- Factory service: we support packing, labeling, and batch traceability.

- Wholesale options: we support bulk orders and repeat supply plans.

FAQ

Is tabular alumina good for dense ceramic parts?

Yes. Tabular alumina for ceramic parts is often used to raise density and strength. It also supports stable performance in heat and wear.

Which particle sizes should I use for ceramic parts?

It depends on your forming method and your part thickness. Many ceramic parts use mixed grading. This improves packing and can reduce shrinkage.

What should I ask a supplier before buying?

Ask for COA, PSD, density, porosity, and batch control limits. A reliable Manufacturer or Supplier will provide clear and recent data.

Can tabular alumina help with thermal shock?

It can help in many cases because of its stable structure and low porosity. But thermal shock also depends on design, firing profile, and bonding system.

How do I request a quote?

Visit banlanchem.com and send your target grade, particle size, order volume, and shipping term. We will reply with a clear offer.