How Tabular Alumina Is Produced: Step-by-Step Manufacturing Guide

How tabular alumina is produced is a common question from refractory engineers, buyers, and sourcing teams. In 2025, more companies look for stable quality, clear process control, and long-term supply from a reliable Manufacturer, Supplier, Factory, or Wholesale partner. This page explains the tabular alumina production process step by step, using short sentences, simple words, and clear lists.

Table of Contents

- 1. Quick Overview: How Tabular Alumina Is Produced

- 2. What Is Tabular Alumina?

- 3. Why the Production Process Matters

- 4. Step 1: Select High-Purity Alumina Raw Material

- 5. Step 2: Mix, Grind, and Homogenize

- 6. Step 3: Form Pellets or Shapes

- 7. Step 4: Sinter at Very High Temperature

- 8. Step 5: Cool, Crush, and Size (Grading)

- 9. Step 6: Screening, Quality Control, and Packaging

- 10. Where Tabular Alumina Is Used

- 11. Buying Tips: Manufacturer, Supplier, Factory, Wholesale

- 12. FAQ

- 13. Conclusion

1. Quick Overview: How Tabular Alumina Is Produced

Tabular alumina is produced by sintering high-purity alumina at very high temperature. The material does not melt. It densifies. Large α-alumina crystals grow. Then the sintered blocks are crushed and graded into different sizes.

Simple process flow

- High-purity alumina selection

- Mixing and grinding

- Pellet forming

- High-temperature sintering (about 1800°C)

- Cooling and crushing

- Screening and grading

- Quality control and packaging

2. What Is Tabular Alumina?

Tabular alumina is a high-density α-Al2O3 material. It has low porosity. It is stable at high temperatures. It is widely used in refractory castables, bricks, and kiln furniture.

Many buyers use tabular alumina because it offers:

- High bulk density

- Low apparent porosity

- Strong thermal shock resistance

- Good corrosion resistance

- Stable performance in steel and cement kilns

If you are new to alumina materials, the article What Is Alumina provides a clear introduction to alumina types and properties.

Tabular alumina is a sintered form of high-purity α-alumina. According to widely accepted material definitions, α-alumina is the most stable crystalline phase of alumina at high temperatures.

For a general material overview, you can also refer to the definition of alumina on Wikipedia.

Product reference (internal link): Tabular Alumina

3. Why the Production Process Matters

The tabular alumina production process decides final quality. It affects density, porosity, and strength. Small process differences can cause big performance changes in refractories.

For a Manufacturer or Factory, stable process control means stable batches. For a Supplier or Wholesale buyer, stable batches mean fewer production problems.

Key quality targets

- High bulk density

- Low porosity

- Low impurities

- Stable particle size distribution

The difference between sintered and fused materials is also explained in our comparison article on Tabular Alumina vs Fused Alumina, which helps buyers choose the right material.

Material engineers generally agree that density and porosity strongly influence refractory performance, a principle also described by ASM International in ceramic material references.

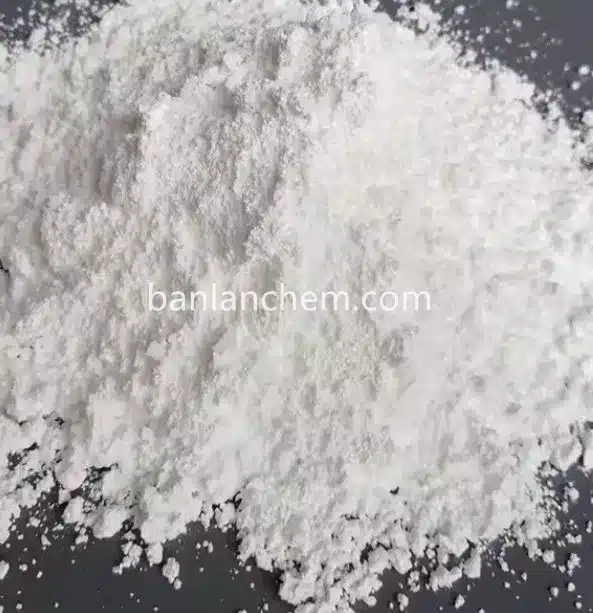

4. Step 1: Select High-Purity Alumina Raw Material

The first step in how tabular alumina is produced is raw material selection. Most producers start with high-purity alumina powder. Purity is often ≥ 99.3% Al2O3.

Why purity matters:

- Fewer impurities means better crystal growth

- Better crystal growth means higher density

- Higher density means stronger refractory performance

Raw material quality is closely related to alumina treatment methods, which are further discussed in the article Calcined Alumina Polishing.

Related internal product link: Calcined Alumina

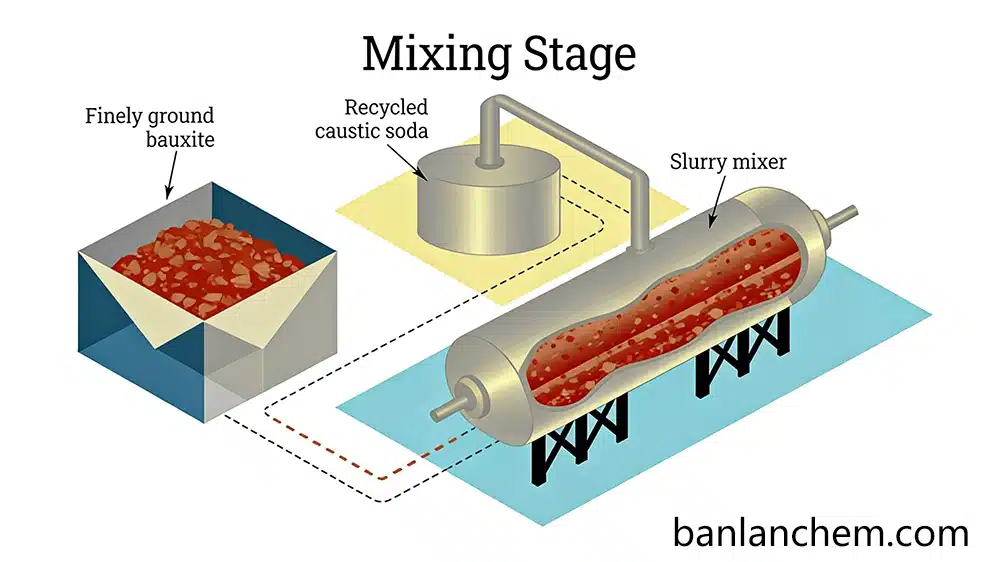

5. Step 2: Mix, Grind, and Homogenize

Next, the alumina powder is mixed and ground. This creates a uniform particle size. It also helps stable sintering.

What a good factory controls here

- Grinding time

- Moisture level

- Uniform mixing

- Removal of oversized particles

This step supports stable quality. It helps the Manufacturer deliver consistent tabular alumina to global customers.

6. Step 3: Form Pellets or Shapes

The mixed powder is formed into pellets, balls, or compact shapes. This helps the kiln heat the material evenly.

Common forming methods

- Pelletizing

- Pressing

- Extrusion

7. Step 4: Sinter at Very High Temperature

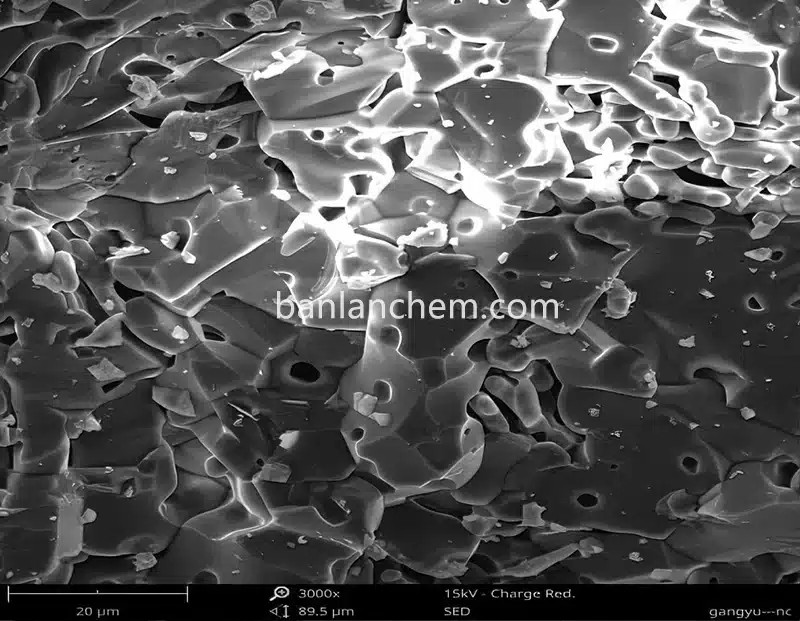

This is the core step in how tabular alumina is produced. The formed material is fired in a high-temperature kiln. The temperature is often around 1800°C. The material sinters. It becomes dense. It does not melt.

What happens during sintering

- α-alumina crystals grow into tabular shapes

- Porosity drops

- Strength increases

- Structure becomes stable for high-temperature use

8. Step 5: Cool, Crush, and Size (Grading)

After firing, the material is cooled. Then it is crushed into smaller pieces. After that, it is graded into different sizes. Different customers need different sizes.

Common size ranges

- 0–1 mm

- 1–3 mm

- 3–5 mm

- 5–8 mm

- Fines (powder)

OEM projects may need custom grades. A strong Factory can support custom sizing for Wholesale buyers.

9. Step 6: Screening, Quality Control, and Packaging

Before shipment, the material is screened and tested. This step helps the Supplier provide stable product to customers.

Typical quality checks

- Chemical analysis (Al2O3 content)

- Bulk density

- Apparent porosity

- Particle size distribution

- Visual inspection for impurities

Common packaging

- 25 kg bags

- 1-ton jumbo bags

- OEM/ODM labeling for distributors

10. Where Tabular Alumina Is Used

Tabular alumina is used in many high-temperature and high-wear applications.

- Refractory castables

- Refractory bricks

- Steel ladles and tundishes

- Cement kiln linings

- Incinerators

- Ceramics and kiln furniture

Related internal article link: Tabular Alumina Application

11. Buying Tips: Manufacturer, Supplier, Factory, Wholesale

If you are buying tabular alumina in 2025, focus on quality stability. Also focus on supply reliability. Price matters, but stable performance matters more.

Questions to ask your manufacturer or supplier

- What is your typical bulk density and porosity range?

- How do you control kiln temperature and firing time?

- Do you provide COA and batch traceability?

- Can you supply stable grading for long-term orders?

- Do you support OEM packaging for wholesale distribution?

A good Manufacturer and Factory can support long-term projects. A professional Supplier can help you choose the right grade. For large volume, Wholesale supply should be stable and predictable.

12. FAQ

Q1: Is tabular alumina the same as fused alumina?

No. Fused alumina is melted in an electric arc furnace. Tabular alumina is sintered at very high temperature without melting.

Q2: Why is 1800°C important?

It helps α-alumina crystals grow fully. It also helps reduce porosity and increase density.

Q3: Can I order custom particle sizes?

Yes. Many factories support custom sizing for OEM projects and wholesale orders.

Q4: Which industries use tabular alumina most?

Refractories, steel plants, cement kilns, and ceramic producers.

13. Conclusion

How tabular alumina is produced can be explained in clear steps. It starts with high-purity alumina. It requires careful mixing and forming. Then it goes through high-temperature sintering. After that, it is crushed, graded, tested, and packed. Each step impacts final quality.

If you need stable tabular alumina from a reliable Manufacturer, Supplier, Factory, or Wholesale partner, BanlanChem provides tabular alumina solutions and export support. Product reference: Tabular Alumina