What is the Difference Between Alumina and Boehmite?

Introduction

When discussing advanced ceramic and chemical materials, the question often arises: what is the difference between alumina and boehmite? Although both are derived from aluminum compounds, their chemistry, structure, and industrial roles differ greatly.

As a professional supplier of Alumina material and Boehmite powder, we frequently help customers distinguish between these two materials to make better sourcing and R&D decisions.

Core Definitions

Alumina (Al₂O₃)

- Pure oxide of aluminum.

- Exists in several crystalline phases: α, γ, δ, θ.

- α-Alumina is dense, strong, and stable.

- γ-Alumina is porous, with high surface area.

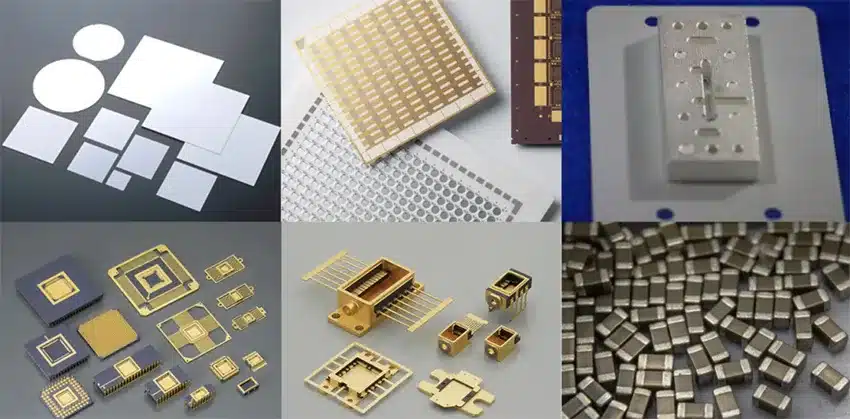

- Widely used for refractories, ceramics, abrasives, and catalyst supports.

Boehmite (γ-AlOOH)

- Aluminum oxyhydroxide, containing structural hydroxyl groups.

- Typically used as a precursor to γ-Alumina.

- Disperses well in aqueous systems, forming sols and gels.

- Applied in catalyst binders, flame-retardant fillers, coatings, and membrane materials.

Physical properties

- Chemical formula

- Alumina: Al₂O₃.

- Boehmite: AlOOH.

- Hydroxyl content

- Alumina: none.

- Boehmite: present, surface and structural.

- Surface area (typical)

- Alpha-alumina: very low.

- Gamma-alumina: high, often 100–300 m²/g.

- Boehmite: moderate as-is; becomes high after calcination.

- Hardness and strength

- Alumina: very hard and wear resistant.

- Boehmite: softer; used mainly as precursor or additive.

- Thermal behavior

- Alumina: very refractory.

- Boehmite: dehydrates, then converts to alumina phases.

- Dispersibility

- Alumina: varies with phase and surface treatment.

- Boehmite: peptizes to stable sols under acid conditions.

Technical Comparison

Key takeaway: Alumina is the final, stable oxide. Boehmite is an intermediate phase with higher reactivity.

| Property | Alumina (Al₂O₃) | Boehmite (γ-AlOOH) |

|---|---|---|

| Chemistry | Oxide | Oxyhydroxide |

| Phases | α, γ, δ, θ | Orthorhombic |

| Surface area | Low (α), High (γ) | Medium → High (after calcination) |

| Thermal stability | Excellent, up to 2000 °C | Converts on heating |

| Applications | Refractory, ceramics, polishing | Catalyst binder, precursor, flame-retardant |

Typical Specifications

Alumina Powder (γ-Al₂O₃)

- Al₂O₃: ≥ 99.8%

- Na₂O: ≤ 0.3%

- BET surface area: 150–250 m²/g

- Particle size (D50): 3–10 μm

Boehmite Powder (γ-AlOOH)

- AlOOH content: ≥ 99.5%

- Loss on ignition (LOI): 15–18%

- Particle size (D50): 1–3 μm

- Dispersibility: Excellent in acidic aqueous solutions

Detailed specifications can be found on our Boehmite product page.

Application Insights

- Alumina is best for: refractory bricks, ceramics, abrasive powders, catalyst supports.

- Boehmite is best for: catalyst shaping, sol-gel processes, flame retardancy, membrane preparation.

In catalyst manufacturing, customers often start with boehmite due to its di1. What is the difference between alumina and boehmite?

Alumina is aluminum oxide (Al₂O₃), stable and refractory. Boehmite is aluminum oxyhydroxide (AlOOH), a precursor that transforms into alumina on heating.

Selection guide by goal

Use this checklist to choose fast.

- High temperature strength? Choose alpha-alumina.

- High surface area support? Choose γ-alumina, often from boehmite.

- Need to tailor pore size? Start with boehmite, then calcine.

- Want easy dispersion in water? Boehmite peptizes well.

- Abrasive or polishing? Use alumina, grade as needed.

- Catalyst shaping and binding? Use boehmite for green strength.

- Dense ceramic with minimal porosity? Use alpha-alumina or sinter to alpha.

FAQs: What is the difference between alumina and boehmite?

Is boehmite a type of alumina?

Not exactly. Boehmite is AlOOH. It turns into γ-alumina after heating.

Which is better for catalyst supports?

Use γ-alumina for the support. Start from boehmite to tune pores and surface area.

Which is better for high-temperature ceramics?

Alpha-alumina is best. It is dense and stable at high temperature.

Can I use boehmite directly as a flame-retardant filler?

Yes, as a synergist. It releases water on heating and helps with char formation.

At what temperature does boehmite become alumina?

Commonly around 400–600 °C for γ-alumina. Final α-alumina needs much higher temperatures.

Why choose boehmite instead of buying γ-alumina?

Control. You can design the pore structure by adjusting the calcination steps.

Conclusion

The difference between alumina and boehmite lies in their chemistry and application. Alumina is the stable oxide used in refractories, ceramics, abrasives, and catalyst supports. Boehmite is the reactive oxyhydroxide precursor, ideal for sol-gel processing, binders, and flame-retardant formulations.

At BanlanChem, we provide both high-purity alumina and boehmite powders, tailored to industrial needs. Our technical team can recommend the right grade for your project.

📩 Contact us to request detailed specifications, samples, or technical consultation.